An electrolytic stripping device and method for carbon extraction replication of steel mounted samples

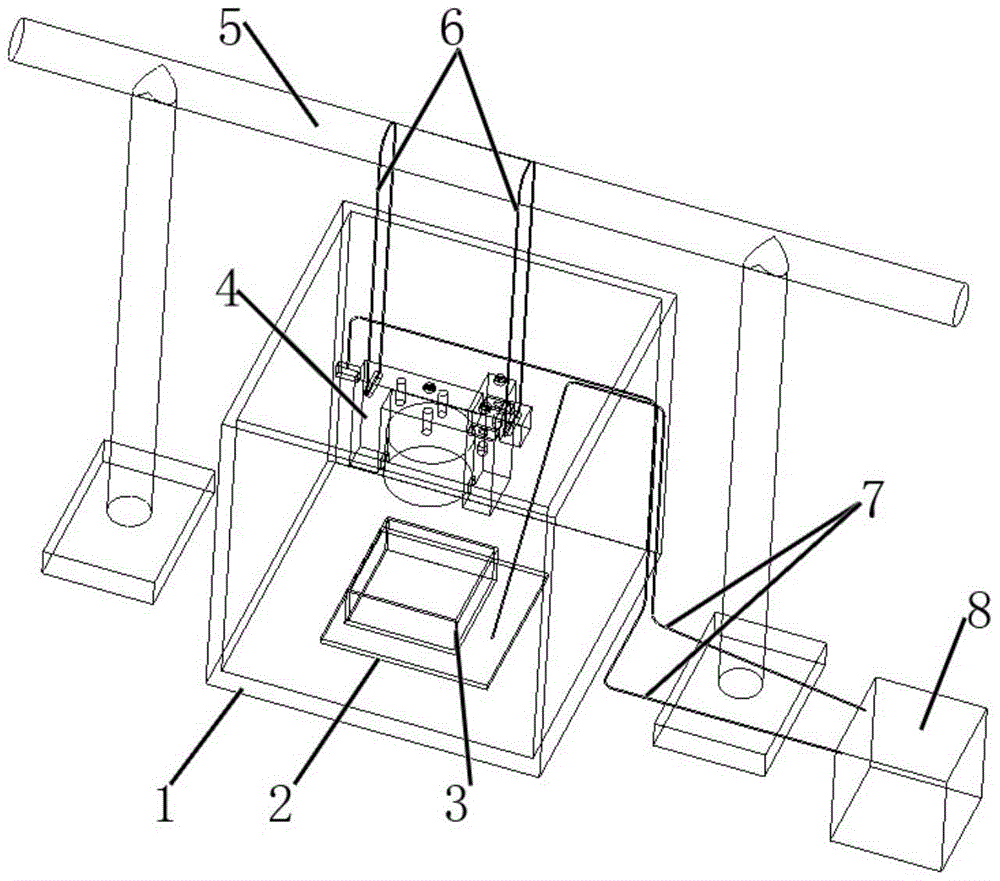

A technology of extraction replica and membrane device, applied in the field of analysis of iron and steel material precipitates, can solve the problems of hours or even dozens of hours, high requirements for operator experience, and great influence on test results, so as to improve the stripping speed, Safe operation, convenient and quick effect of removing carbon film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

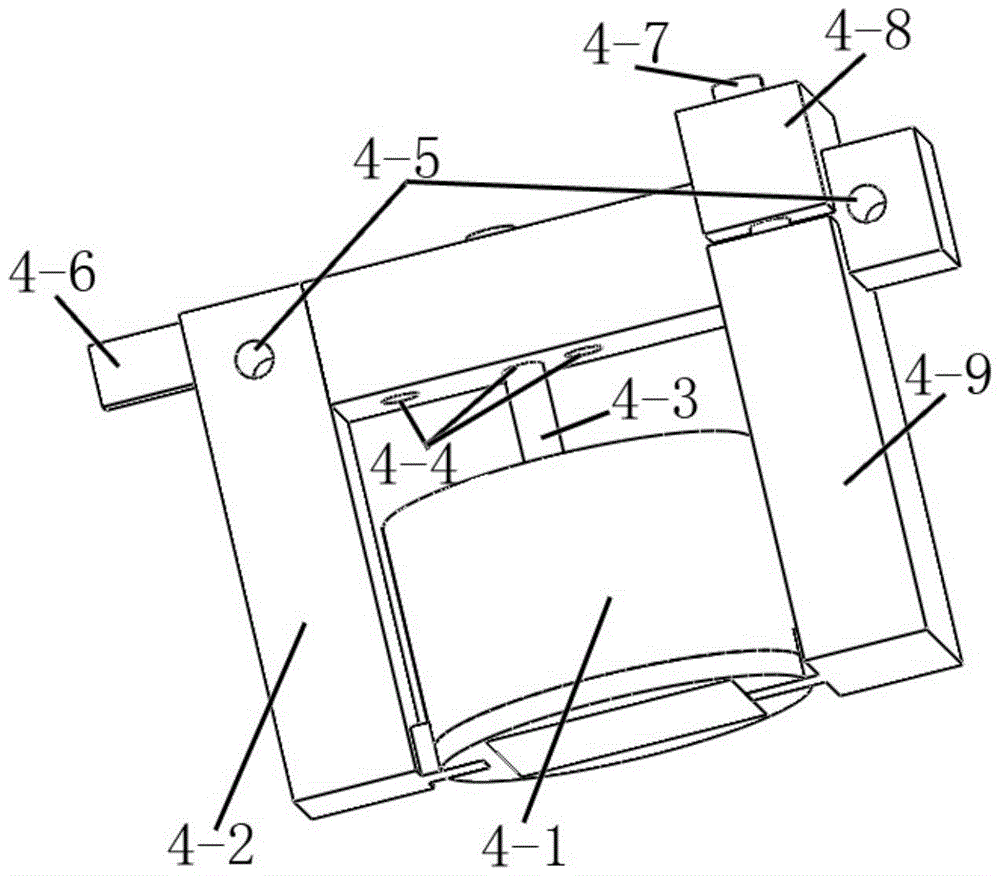

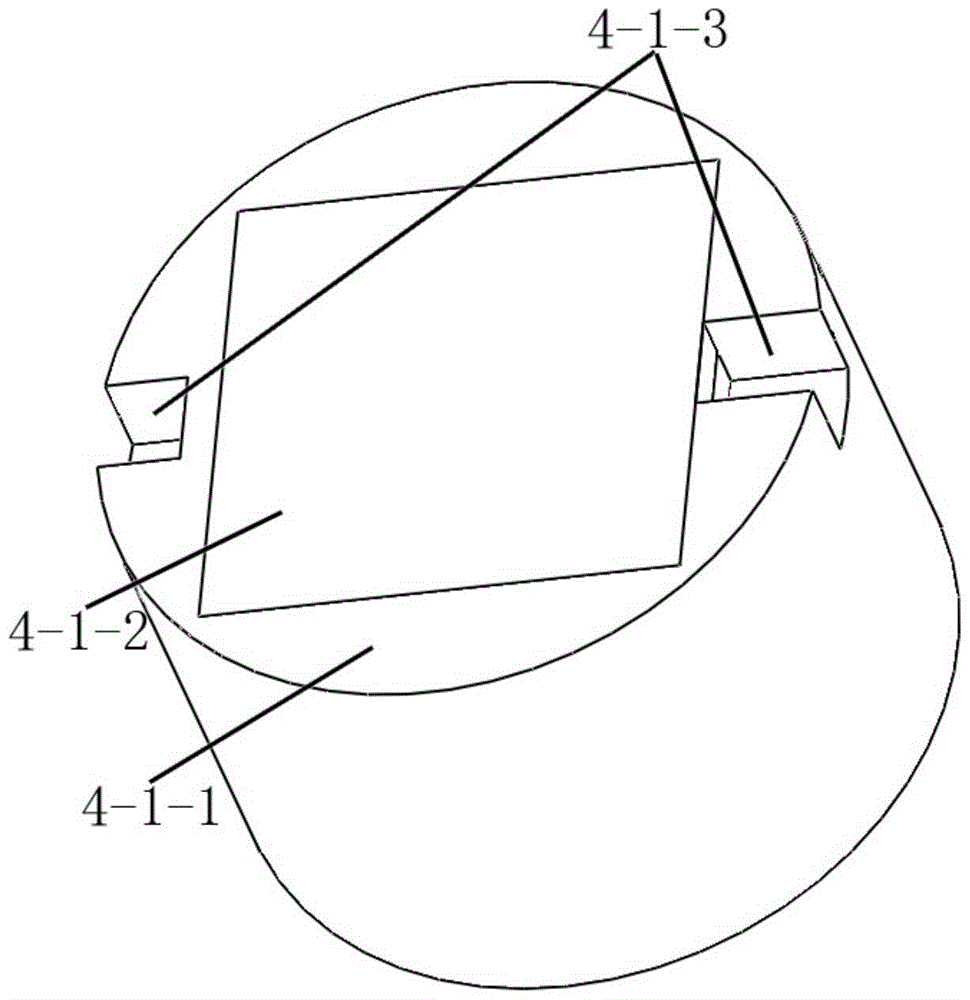

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will now be described in detail below.

[0044] 1. To prepare a special mount of thin-flaky corrosion-resistant steel containing V precipitates, the steps are as follows:

[0045] (1) Use a cutting machine or other methods to obtain two small squares with a size of 4mm×5mm×6mm;

[0046] (2) Place the sample to be mounted and the small cube in the hot-mounting mold, one side of the small cube is close to the side of the sample to be mounted, and the other small cube is as tangent as possible to the edge of the hot-mounting mold;

[0047](3) The sample is mounted on the grinding and polishing machine, and the two sides with the small squares are ground until the plane with two small square sides is exposed;

[0048] (4) Use a utility knife to draw a small pit at the junction of the lower edge of the small square and the inlay, and then use a flat-head screwdriver with a width slightly smaller than the width of the small square to pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com