Spray coke-removal/powder rubbing treatment agent for synthetic leather and preparation method thereof

A treatment agent and synthetic leather technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of low contrast of burnt feeling of products, large amount of organic matter in treatment agent, and low degree of fineness of powdery feeling, so as to achieve superior leathery feeling, Good gloss effect, excellent color development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

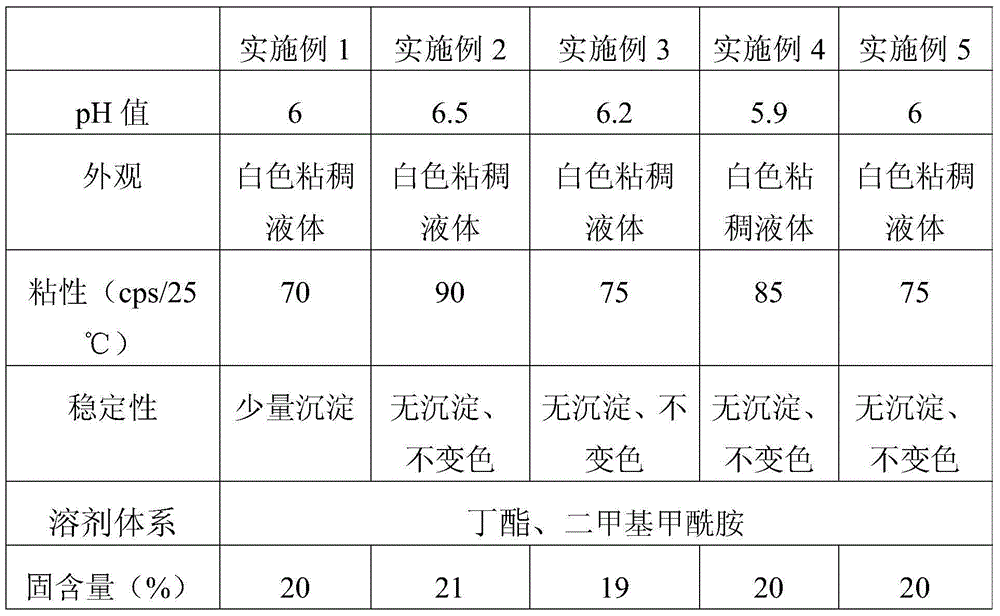

Examples

Embodiment 1

[0025] The synthetic leather is made up of the components of the following proportions: 23 parts by weight of modified polyurethane, 18 parts by weight of dimethylformamide, 20 parts by weight of butyl ester, 25 parts by weight of ethylene dichloride, 5 parts by weight of wax powder, 5 parts by weight of silica matting powder, 1 part by weight of water repellent, 1 part by weight of modified phenyl silicone oil, and 0.5 part by weight of dispersant.

[0026] The preparation method of the above-mentioned synthetic leather with spraying coke polishing / powder rubbing treatment agent is: under normal temperature and pressure, 11.5 parts by weight of modified polyurethane and 18 parts by weight of dimethylformamide, 20 parts by weight of butyl ester, 25 parts by weight Dichloroethane in parts by weight, wax powder in 5 parts by weight, silica matting powder in 5 parts by weight and dispersant in 0.5 parts by weight are stirred evenly; Stir the modified phenyl silicone oil evenly; f...

Embodiment 2

[0028] The synthetic leather is made up of the components of the following proportions: 25 parts by weight of modified polyurethane, 19 parts by weight of dimethylformamide, 18 parts by weight of butyl ester, 24 parts by weight of ethylene dichloride, 6 parts by weight of wax powder, 7 parts by weight of silica matting powder, 2 parts by weight of water repellent, 2 parts by weight of modified phenyl silicone oil, and 0.1 part by weight of dispersant.

[0029] The preparation method of the above-mentioned synthetic leather with spraying burnishing / powder rubbing treatment agent is: under normal temperature and pressure, 12.5 parts by weight of modified polyurethane and 19 parts by weight of dimethylformamide, 18 parts by weight of butyl ester, 24 parts by weight Parts by weight of dichloroethane, 6 parts by weight of wax powder, 7 parts by weight of silica matting powder and 0.1 parts by weight of dispersant are stirred evenly; add 2 parts by weight of water repellent and 2 par...

Embodiment 3

[0031] The synthetic leather is made up of the components of the following proportions: 26 parts by weight of modified polyurethane, 20 parts by weight of dimethylformamide, 19 parts by weight of butyl ester, 22 parts by weight of ethylene dichloride, 5 parts by weight of wax powder, 6 parts by weight of silica matting powder, 2 parts by weight of water repellent, 2 parts by weight of modified phenyl silicone oil, and 0.4 parts by weight of dispersant.

[0032] The preparation method of the above-mentioned synthetic leather with spraying burnishing / powder rubbing treatment agent is: under normal temperature and pressure, 13 parts by weight of modified polyurethane and 20 parts by weight of dimethylformamide, 19 parts by weight of butyl ester, 22 parts by weight Parts by weight of dichloroethane, 5 parts by weight of wax powder, 6 parts by weight of silica matting powder and 0.4 parts by weight of dispersant are stirred evenly; add 2 parts by weight of water repellent and 2 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com