Organic waste liquid treatment method

A technology of organic waste liquid and treatment method, applied in water/sewage treatment, chemical instruments and methods, flotation water/sewage treatment, etc., can solve the problems of poor biodegradability, high cost, and low COD reduction of organic waste liquid, etc. To achieve the effect of easy control of the treatment process, less power consumption and less investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

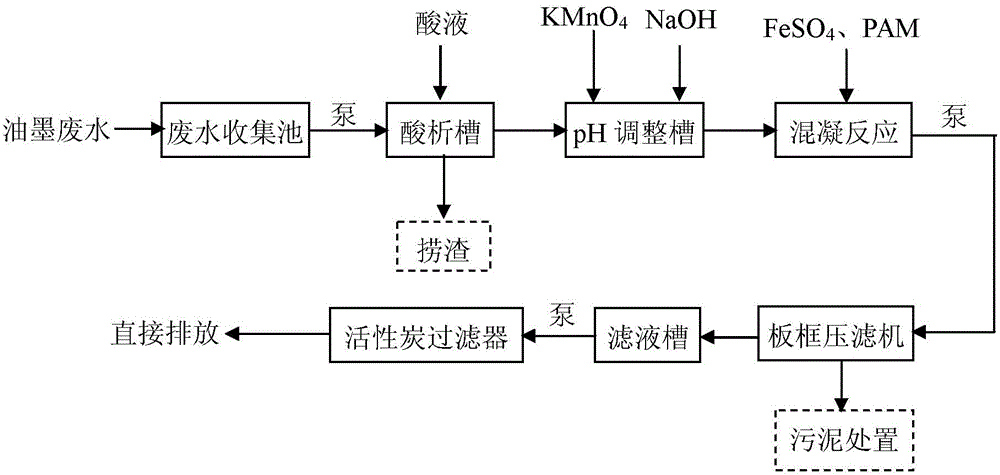

[0024] see figure 2 , the organic waste liquid (ink waste water) generated by the PCB production line is treated by the following methods:

[0025] 1) Adjust the pH of the organic waste liquid to 2-3, aerate and stir, the organic waste liquid will precipitate jelly, and remove the scum;

[0026] 2) Add alkali to adjust the pH value to 8~9, add 1~2g / L potassium permanganate (that is, put 1~2g potassium permanganate into 1L waste liquid), and react for 20~40min;

[0027] 3) Add flocculant FeSO 4 and coagulant PAM, coagulate and precipitate, and then filter through a filter press;

[0028] 4) The filtrate obtained in step 3) is filtered by activated carbon adsorption and discharged up to the standard.

[0029] In the acid analysis treatment of the above step 1), the pH of the organic waste liquid can be adjusted by using the waste acid liquid produced on the PCB produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com