Novel centrifugal melt electrostatic spinning device

A new technology of melt electrospinning, applied in textiles and papermaking, filament/thread forming, fiber processing, etc. The effect of batching silk and avoiding nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is described in further detail below:

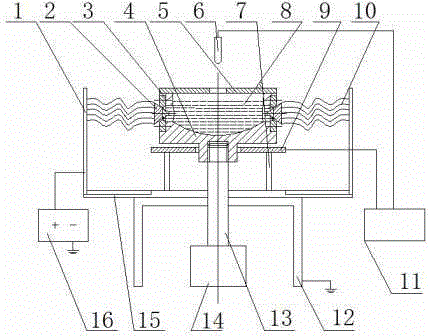

[0009] The invention proposes a centrifugal electrostatic spinning device, which mainly includes a spinning part, a receiving part, an electromagnetic heating part, a high voltage generating part, an electric part and a frame.

[0010] The present invention is a new type of centrifugal melt electrospinning device. The device diagram is shown in figure 1 . like figure 1 The spinning part consists of a liquid storage tank (4), an end cover (5) with a hole in the middle, a truncated cone nozzle assembly 1 (2), and a truncated cone nozzle assembly 2 (3), wherein the truncated cone nozzle assembly 1 (2) and the The frustum nozzle assembly 2 (3) is connected by screws, and then the two are connected with the liquid storage tank (4) by screws, and the liquid storage tank (4) is connected with the shaft (13) through a threaded joint, and the bottom of the liquid storage tank (4) is connected The end cap (5) is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com