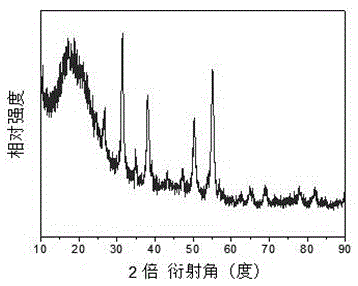

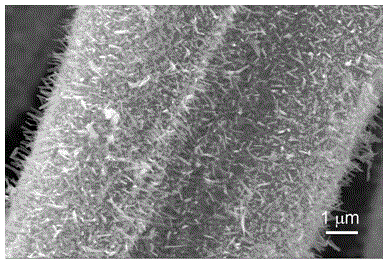

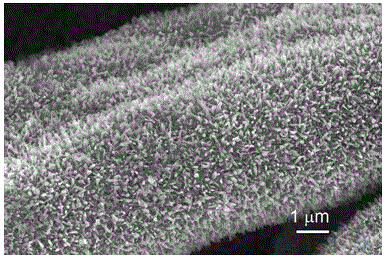

One-dimensional nico on the surface of activated carbon fibers 2 the s 4 Crystal array and its preparation method

A technology of activated carbon fiber and crystal array, applied in the field of one-dimensional NiCo2S4 crystal array and its preparation, to achieve good binding force and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 0.0124g nickel acetate tetrahydrate and 0.0249g cobalt acetate tetrahydrate are jointly dissolved in the 15.0mL mixed solvent system, and the total molar concentration of nickel ion and cobalt ion in the solution is 0.01 mole / liter; Diols are mixed at a volume ratio of 1:1. The ratio of the moles of nickel ions to cobalt ions is 1:2, and magnetic stirring is carried out for 15 minutes to obtain a uniform solution; 0.0219 g of ethylenediaminetetraacetic acid is added to the above solution, and the moles of ethylenediaminetetraacetic acid are 0.075 millimoles, which is equal to Half of the total moles of nickel ions and cobalt ions; stir to dissolve ethylenediaminetetraacetic acid completely; add 0.0571g of thiourea to the above solution, the molar number of thiourea is 0.75 mmol, which is equal to the total moles of nickel ions and cobalt ions 5 times; stir to completely dissolve thiourea; immerse the activated carbon fiber in the above solution for 60 minutes. The fina...

Embodiment 2

[0030]0.0727g nickel nitrate hexahydrate and 0.1455g cobalt nitrate hexahydrate are jointly dissolved in the 15.0mL mixed solvent system, and the total molar concentration of nickel ion and cobalt ion in the solution is 0.05 mol / liter; Diols are mixed at a volume ratio of 1:1. The ratio of the moles of nickel ions to cobalt ions is 1:2, and magnetic stirring is used for 15 minutes to obtain a homogeneous solution; 0.1096 g of ethylenediaminetetraacetic acid is added to the above solution, and the moles of ethylenediaminetetraacetic acid are 0.375 millimoles, which is equal to Half of the total moles of nickel ions and cobalt ions; stir to dissolve ethylenediaminetetraacetic acid completely; add 0.4567g thiourea to the above solution, the molar number of thiourea is 6 millimoles, which is equal to the total molar ratio of nickel ions and cobalt ions 8 times; stir to completely dissolve thiourea; immerse the activated carbon fiber in the above solution for 60 minutes. The final...

Embodiment 3

[0033] 0.1188g nickel chloride hexahydrate and 0.2379g cobalt chloride hexahydrate are dissolved in 15.0mL mixed solvent system, the total molar concentration of nickel ion and cobalt ion in the solution is 0.1 mol / liter; mixed solvent system is made of deionized water It is mixed with ethylene glycol at a volume ratio of 1:1. The ratio of the moles of nickel ions to cobalt ions is 1:2, and magnetic stirring is carried out for 15 minutes to obtain a uniform solution; 0.2192 g of ethylenediaminetetraacetic acid is added to the above solution, and the moles of ethylenediaminetetraacetic acid are 0.75 millimoles, which is equal to Half of the total moles of nickel ions and cobalt ions; stir to dissolve ethylenediaminetetraacetic acid completely; add 1.1418g thiourea to the above solution, the molar number of thiourea is 15 millimoles, which is equal to the total moles of nickel ions and cobalt ions 10 times; stir to completely dissolve thiourea; immerse activated carbon fibers in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com