A kind of lubricating grease composition and preparation method thereof

A grease composition and mixture technology, which is applied in the field of grease, can solve the problems of viscous colloidal substances, grease coking, char residue, etc., and achieve slow coking, good extreme pressure performance, and less char residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a kind of preparation method of the lubricating grease composition described in above-mentioned technical scheme, comprises the following steps:

[0042] mixing polyalphaolefin, polyisobutylene and silicon glycol to obtain a first mixture;

[0043] mixing the first mixture with fumed silica and keeping the temperature constant to obtain a second mixture;

[0044] The second mixture is mixed with an anti-aging agent and a solid lubricant, and then ground to obtain a grease composition.

[0045] In the present invention, polyalpha-olefin, polyisobutylene and silicon glycol are mixed to obtain the first mixture. In the present invention, there is no special limitation on the order of mixing the polyalpha-olefin, polyisobutylene and silicon glycol, preferably the polyalpha-olefin and polyisobutylene are mixed first, and then the silicon glycol is added thereto. The present invention has no special limitation on the mixing equipment, and the ...

Embodiment 1

[0059] Put 800g of base oil, in which PAO20 accounts for 52% and polyisobutylene PB2400 accounts for 48%, add it to the fat-making kettle and heat it up to 30°C, then add 30g of silicon glycol, stir while raising the temperature, after 20min the temperature rises to 150°C Stop stirring to obtain the first mixture;

[0060] When the temperature of the first mixture was raised to 155±5°C, 60 g of fumed silica was added, and stirred at constant temperature for 30 minutes to obtain the second mixture;

[0061] 100 g of molybdenum disulfide and 20 g of DNP were added to the second mixture, and stirred for 10 minutes to obtain a third mixture; the temperature of the third mixture was lowered to 50° C., and the third mixture was ground to obtain a grease composition.

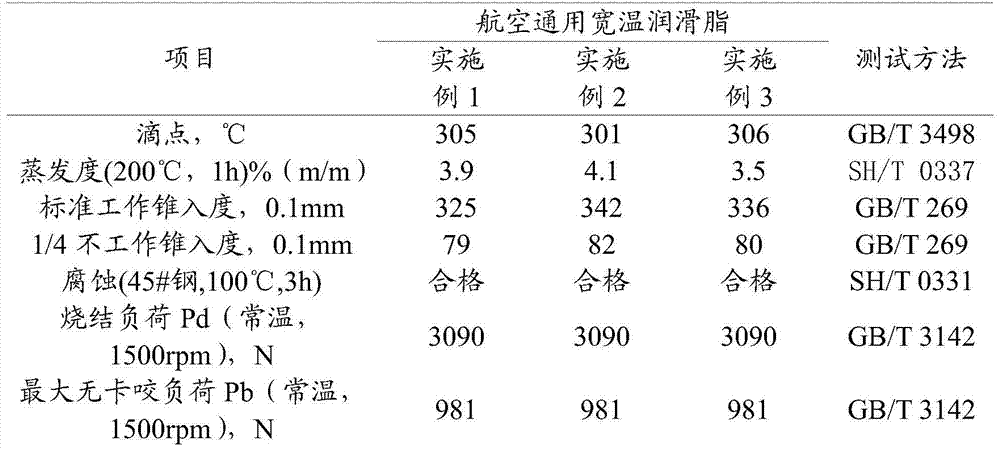

[0062] The present invention performs a performance test on the obtained lubricating grease composition according to the test method described in the above technical scheme, and the test results are shown in Table 1, a...

Embodiment 2

[0064] Add 800g of base oil, in which PAO20 accounts for 57% and polyisobutylene PB2400 accounts for 43%, add it to the fat-making kettle and heat it up to 30°C, then add 30g of silicon glycol, stir while raising the temperature, and heat up to 100°C after 15 minutes Stop stirring to obtain the first mixture;

[0065] When the temperature of the first mixture was raised to 170±5°C, 60 g of fumed silica was added, and stirred at constant temperature for 35 minutes to obtain the second mixture;

[0066] Add 100g of colloidal graphite and 20g of 2,2,4-trimethyl-1,2-dihydroquinoline polymer to the second mixture, and stir for 10min to obtain the third mixture; cool the third mixture to 60°C, The third mixture is subjected to grinding treatment to obtain a grease composition.

[0067] The present invention performs a performance test on the obtained lubricating grease composition according to the test method described in the above technical scheme, and the test results are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com