Preparation method of urea-formaldehyde resin from straw ethanol byproduct

A urea-formaldehyde resin and by-product technology, used in aldehyde/ketone condensation polymer adhesives, adhesive types, adhesive additives, etc., can solve the problems of high free formaldehyde of urea-formaldehyde resin, dependence on water resistance of petroleum products, etc. The effect of enhancing water resistance, realizing resource utilization, and saving oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

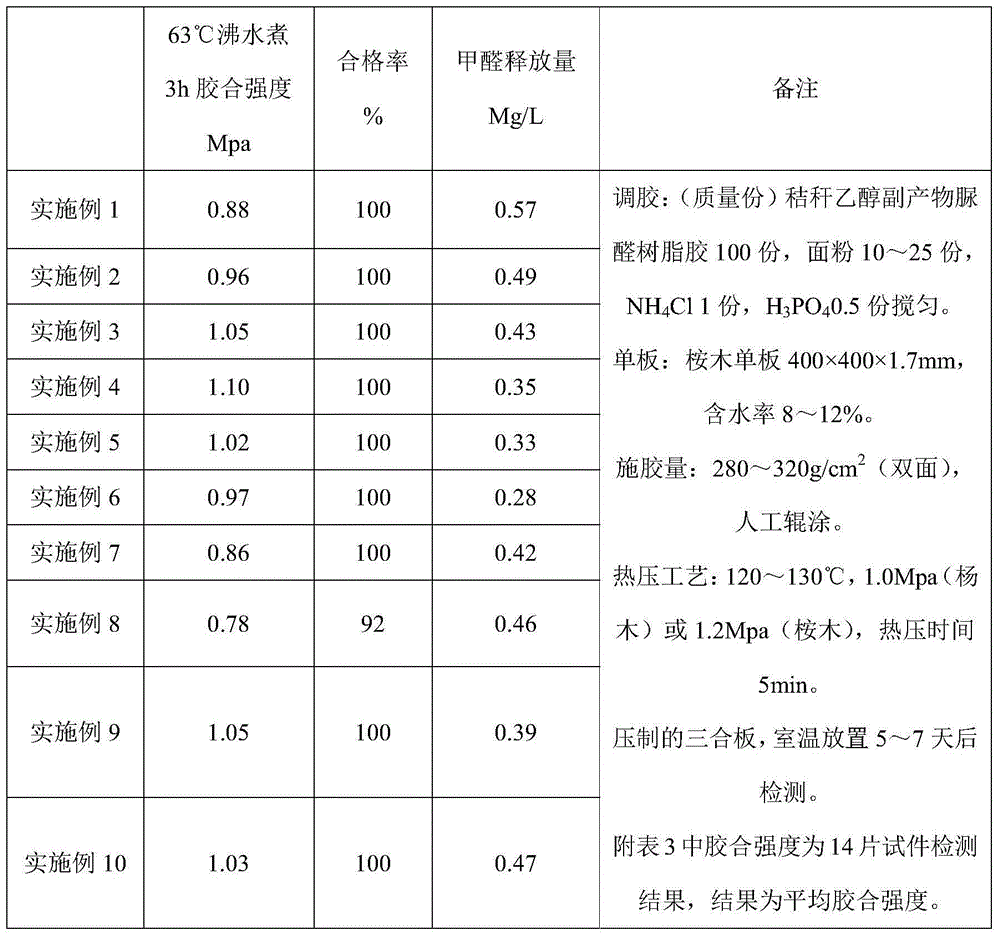

Examples

preparation example Construction

[0017] A method for preparing straw ethanol by-product urea-formaldehyde resin glue, the preparation steps are:

[0018] The first step: add 36.8wt.% formaldehyde solution, water, pre-pressing modifier, the first batch of urea, the first batch of melamine and the first batch of straw ethanol by-products into the reactor, wherein the water / formaldehyde mass ratio is 0.40 ~1.54:1, the mass ratio of pre-press modifier / formaldehyde is 0.001~0.02:1, the mass ratio of the first batch of urea / formaldehyde is 0.70~1.20:1, the mass ratio of the first batch of melamine / formaldehyde is 0.02 ~0.14:1, in order to adjust the pH value to 7.0~9.0, raise the temperature to 80~95℃, react for 30~50min; the second step: adjust the pH to 4.0~6.5, react at 80~95℃, control the reaction at 30min~120min to the cloud point;

[0019] Step 3: Add the second batch of urea, the second batch of melamine and the second batch of straw ethanol by-products, wherein the mass ratio of the second batch of urea / fo...

Embodiment 1

[0024]Step 1: Add 250g of 36.8wt.% formaldehyde solution, 37.8g of water, 0.1g of polyvinyl alcohol 2699, 102.7g of the first batch of urea, 2g of the first batch of melamine and 10g of the first batch of straw ethanol in a 500mL four-necked flask product. Start stirring and adjust the pH value to 7.0 with 30wt.% NaOH solution, raise the temperature to 80°C, and react for 30 minutes;

[0025] The second step: use 20wt.% NH 4 Adjust the pH of the Cl solution to 4.0, and react at 85°C for 30 minutes to the cloud point;

[0026] The third step: add the second batch of urea 34.5g, the second batch of melamine 2g, the second batch of straw ethanol by-product 10g, adjust the pH to 6.0 with 30wt.% NaOH solution, and react at 90°C for 30min;

[0027] Step 4: Add the third batch of melamine 12g and straw ethanol by-product 10g, adjust the pH value to 7.1 with 30wt.% NaOH solution, and react at 90°C for 30min.

[0028] Step 5: Cool down to 70°C, add the third batch of urea 34g, react...

Embodiment 2

[0031] Step 1: Add 250g of 36.8wt.% formaldehyde solution, 50.8g of water, 0.7g of polyvinyl alcohol 1799, 90g of the first batch of urea, 4g of the first batch of melamine and 15g of the first batch of straw ethanol by-products in a 500mL four-neck flask . Start stirring and adjust the pH value to 7.5 with 30wt.% NaOH solution, raise the temperature to 85°C, and react for 40min;

[0032] The second step: use 20wt.% NH 4 Adjust the pH of the Cl solution to 4.5, and react at 90°C for 80 minutes to the cloud point;

[0033] Step 3: add the second batch of urea 27.5g, the second batch of melamine 4g, the second batch of straw ethanol by-product 15g, react at 90°C for 30min, and adjust the pH to 6.5 with 30wt.% NaOH solution;

[0034] Step 4: Add the third batch of melamine 24g and straw ethanol by-product 15g, adjust the pH value to 7.5 with 30wt.% NaOH solution, and react at 85°C for 40min.

[0035] Step 5: Cool down to 70°C, add the third batch of urea 27.5g, react for 10min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com