Preparation method for polymer carbon material

A technology of carbon materials and polymers, applied in the field of preparation of polymer carbon materials, can solve problems such as complex adsorption and storage mechanisms, achieve the effect of less process steps, less by-products, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

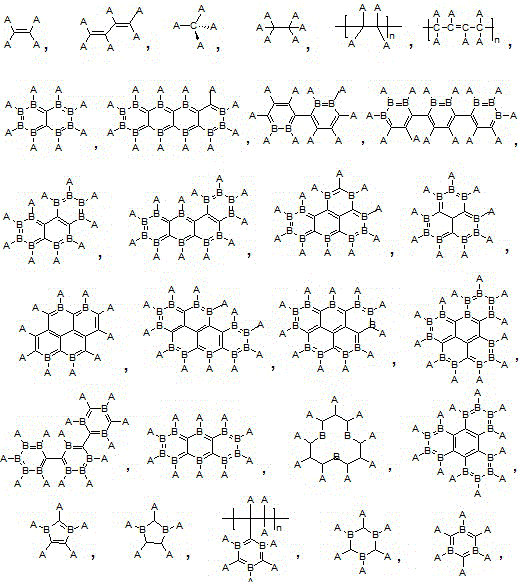

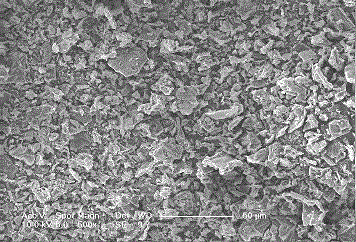

Image

Examples

Embodiment 1

[0044] Embodiment 1, the synthesis of polymer carbon material

[0045] In a clean and dry reactor, add 100 mL of toluene, 30 mL of tetrahydrofuran, 3.0 g of sodium metal, 6.0 g of hexabromobenzene, and 3.0 g of polyvinyl chloride. After 8 hours of reflux reaction under the protection of argon, stop heating and cool to room temperature. Obtain a black polymer carbon material suspension, then add 20 milliliters of absolute ethanol, stir and react for 2 hours, then filter the crude polymer carbon material product under reduced pressure, wash it with acetone 3 times, water 3 times, and 10% hydrochloric acid 2 times, and then washed with water several times until neutral, and dried in vacuum to obtain a pure polymer carbon material.

Embodiment 2

[0046] Embodiment 2, the synthesis of polymer carbon material

[0047] In a clean and dry reactor, add 100 mL of toluene, 2.0 g of sodium metal, 4.0 g of trichlorotribromobenzene, and 2.0 g of trichloropyridine. After 8 hours of reflux reaction under nitrogen protection, stop heating and cool to room temperature to obtain black Polymer carbon material suspension, then add 50 ml of absolute ethanol, stir and react for 2 hours, then filter the crude polymer carbon material product under reduced pressure, wash it with acetone for 3 times, water for 3 times, and 10% phosphoric acid for 2 times , and then washed with water several times until neutral, and dried in vacuum to obtain a pure polymer carbon material.

Embodiment 3

[0048] Embodiment 3, the synthesis of polymer carbon material

[0049] In a clean and dry reaction kettle, add 10mL xylene, 50mL tetrahydrofuran, 3.0g polychloroprene, 3.0g sodium metal, and 6.0g tribromobenzene. After reflux reaction for 10 hours, stop heating and cool to room temperature to obtain a black polymer Carbon material suspension, then add 30 ml of anhydrous methanol, after stirring for 2 hours, the crude product of polymer carbon material filtered under reduced pressure, then wash 3 times with acetone, wash 3 times with water, wash 2 times with 10% sulfuric acid, and then Wash with water several times until neutral, and dry in vacuum to obtain a pure polymer carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com