Method for simultaneously extracting and separating chlorogenic acid, solanesol, alkaloid and rutin in tobacco

A technology of solanesol and rutin, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of unsatisfactory extraction process, high extraction temperature, and low extraction rate, so as to reduce energy consumption, Efficient extraction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

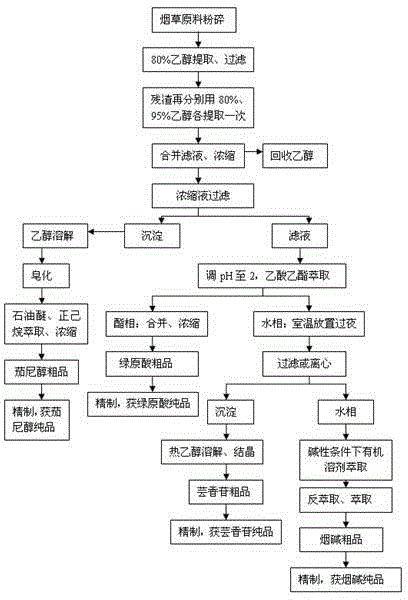

[0021] Such as figure 1 A method for simultaneously extracting and separating tobacco chlorogenic acid, solanesol, nicotine, and rutin is shown, and its steps include:

[0022] 1. Simultaneous extraction of tobacco chlorogenic acid, solanesol, nicotine and rutin

[0023] Weigh 500g of the pulverized tobacco powder sample, extract once with 80% ethanol at a solid-liquid ratio of 1:10, ultrasonic frequency 45 KHz, extraction temperature 40-50°C, and then use 80% and 95% ethanol to remove the residue Each extraction was performed once for 20 minutes; the obtained extracts were combined to obtain extracts of tobacco chlorogenic acid, solanesol, nicotine, and rutin, and the extraction rates of the four components all reached 100%.

[0024] 2. Separation of tobacco chlorogenic acid, solanesol, nicotine and rutin

[0025] 1. Separation of solanesol

[0026] The extract obtained in step 1 was concentrated under reduced pressure at 50°C until there was no alcohol smell, and the eth...

Embodiment 2

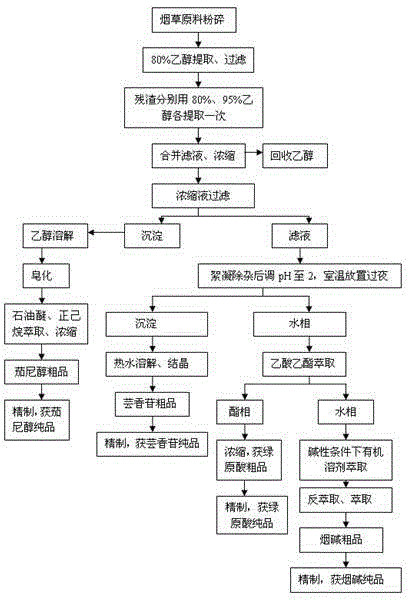

[0033] Such as figure 2 As shown, the difference from Example 1 is:

[0034] 2. Separation of tobacco chlorogenic acid, solanesol, nicotine and rutin

[0035] 1. Separation of solanesol

[0036] The extract was concentrated under reduced pressure at 50°C until there was no alcohol smell, and ethanol was recovered. After the concentrated solution is cooled, it is quickly filtered, solanesol remains in the precipitate, and chlorogenic acid, rutin, and nicotine remain in the filtrate. Wash the precipitate with 20-40% ethanol solution, dissolve it in absolute ethanol, add 30% sodium hydroxide solution, saponify at 40-50°C under ultrasonic conditions for 40min, add deionized water after saponification, and then extract with petroleum ether 3 times, the extracts were combined and concentrated to obtain crude solanesol. The crude solanesol is refined by column chromatography, preparative chromatography, crystallization and other methods to obtain pure solanesol.

[0037] 2. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com