Super-hydrophilic self-cleaning antifogging composite film, and preparation method and application thereof

A composite film and super-hydrophilic technology, applied in the field of super-hydrophilic self-cleaning anti-fog composite film and its preparation, can solve the problems of low utilization rate of sunlight and low quantum efficiency, and achieve simple process flow and fast operation. Simple and good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention uses a sol-gel process. 5g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 4.2 mL HNO 3 Then add 2 g citric acid, 4 mL Triton X-100 (OP), 2 mL polyethylene glycol 200 and 10 mL acetone, stir for 5 h, then add copper sulfate pentahydrate (CuSO 4 ·5H 2 O), and then stirred again (where the stirring speed was 25 r / min and the temperature was 30°C) for 3 h to obtain Cu-Bi with a molar ratio of n(Cu):n(Bi)=5%. 2 o 3 sol; tetraethyl orthosilicate (TEOS) was dissolved in absolute ethanol (EtOH), and then added dropwise to polyoxyethylene (4) ether lauryl alcohol (Brij R 30) In the mixed solution with hydrochloric acid, the mixed solution of the reactants was obtained, and then stirred in a collector type constant temperature heating magnetic stirrer (where the stirring speed was 20 r / min, and the temperature was 30°C) to obtain SiO 2 Sol, of which tetraethyl orthosilicate: Brij R30: hydrochloric acid: absolute ethanol=8: 0.9: 1: 50...

Embodiment 2

[0031] The present invention uses a sol-gel process. 6g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 5.5 mL HNO 3 Then add 2.5 g citric acid, 5 mL Triton X-100 (OP), 2.5 mL polyethylene glycol 200 and 13 mL acetone, stir for 5.5 h, then add copper sulfate pentahydrate (CuSO 4 ·5H 2 O), and then stirred again (where the stirring speed was 20 r / min and the temperature was 35°C) for 2.5 h to obtain Cu-Bi with a molar ratio of n(Cu):n(Bi)= 3%. 2 o 3 sol; tetraethyl orthosilicate (TEOS) was dissolved in absolute ethanol (EtOH), and then added dropwise to polyoxyethylene (4) ether lauryl alcohol (Brij R 30) In the mixed solution with hydrochloric acid, the mixed solution of the reactants was obtained, and then stirred in a collector type constant temperature heating magnetic stirrer (where the stirring speed was 25 r / min, and the temperature was 35°C) to obtain SiO 2 Sol, of which tetraethyl orthosilicate: Brij R 30: hydrochloric acid: absolute ethanol=24:...

Embodiment 3

[0033] The present invention uses a sol-gel process. With 7.5g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 6.3 mL HNO 3 Then add 3 g citric acid, 6 mL Triton X-100 (OP), 3 mL polyethylene glycol 200 and 15 mL acetone, stir for 6 h, then add copper sulfate pentahydrate (CuSO 4 ·5H 2 O), and then stirred again (where the stirring speed was 15 r / min, and the temperature was 25°C) for 2 h to obtain Cu-Bi with a molar ratio of n(Cu):n(Bi)=7%. 2 o 3 sol; tetraethyl orthosilicate (TEOS) was dissolved in absolute ethanol (EtOH), and then added dropwise to polyoxyethylene (4) ether lauryl alcohol (Brij R 30) In the mixed solution with hydrochloric acid, the mixed solution of the reactants was obtained, and then stirred in a collector type constant temperature heating magnetic stirrer (the stirring speed was 15 r / min, and the temperature was 25°C) to obtain SiO 2 Sol, of which tetraethyl orthosilicate: Brij R 30: hydrochloric acid: absolute ethanol=32: 0.9: 1...

PUM

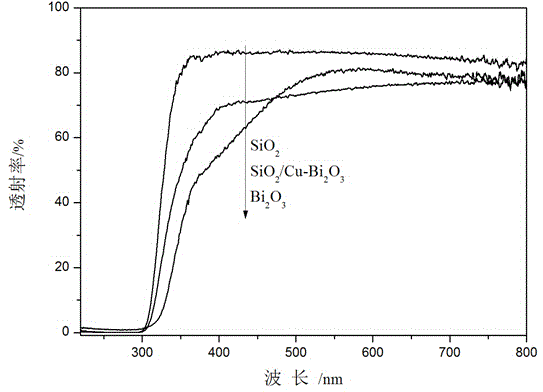

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com