Fusion shrinkage preparation method of core rod of optical fiber preform rod

A technology of optical fiber prefabricated rods and core rods, which is applied in the field of optical fiber manufacturing, can solve problems such as insufficient corrosion and unstable water peaks of core rods, and achieve the effects of improving efficiency, avoiding core refractive index depression, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

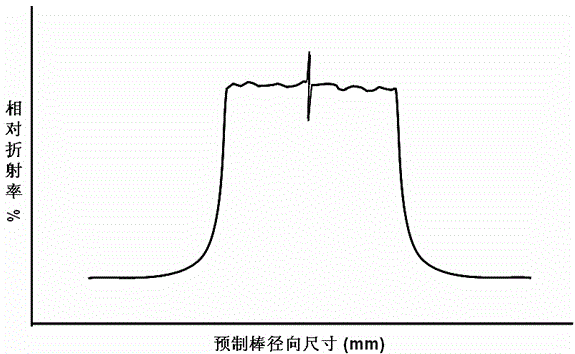

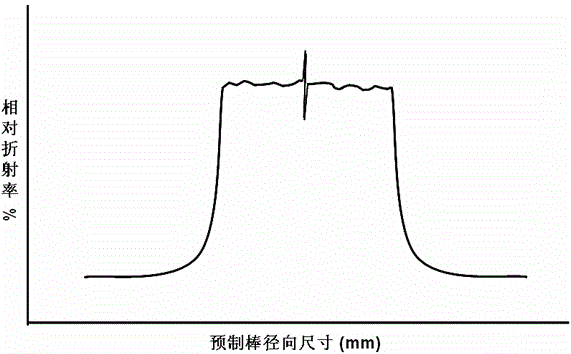

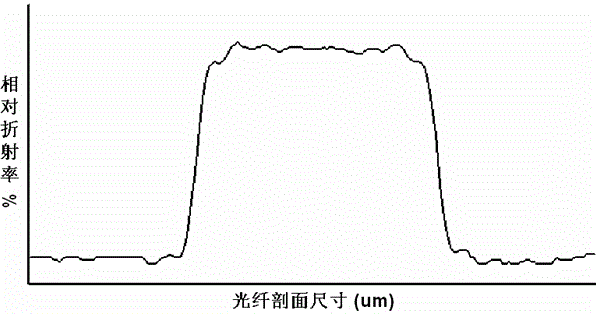

Image

Examples

Embodiment 1

[0024] Embodiment 1: Take the deposited SiO with an outer diameter of 35 mm, a single side wall thickness of 3.5 mm, and a length of 1 m. 2 Liner with doped SiO deposited on the inner wall 2 (with GeO 2 etc.), install it on the preform (mandrel) shrinkage equipment;

[0025] Use a graphite heating furnace as the heat source, the axial length of the heating area of the heating element is 100mm, the furnace body moves at a speed of 20-25mm / min, the surface temperature of the liner is about 1900-2000°C, and the rotation speed of the quartz liner is 15rad / min;

[0026] When the temperature of the heating element rises to 1900°C, the first melting and shrinkage begins, and the mixed gas O is introduced from one end of the liner. 2 and C 2 f 6 , the gas flow is precisely controlled by the flow controller, and the gas pressure at the gas outlet end of the liner is controlled at the same time, and it is stabilized within a certain range to ensure a uniform and controllable chan...

Embodiment 2

[0027] Embodiment 2: Take the deposited SiO with an outer diameter of 45 mm, a single side wall thickness of 15 mm, and a length of 2.5 m. 2 Liner with doped SiO deposited on the inner wall 2 (with GeO 2 etc.), place it on the preform (mandrel) shrinkage equipment;

[0028] Using a graphite heating furnace as a heat source, the axial length of the heating area of the heating element is 300mm, the furnace moves at a speed of 40-45mm / min, the surface temperature of the liner is about 2000-2100°C, and the rotation speed of the quartz liner is 24rad / min;

[0029] When the temperature of the heating element rises to 2000°C, the first melting and shrinkage begins, and the mixed gas (O 2 / C2 f 6 ), the gas flow is accurately controlled by the flow controller, and the gas pressure at the gas outlet of the liner is controlled at the same time, and it is stabilized within a certain range to ensure a uniform and controllable change in the outer diameter of the mandrel. When the furn...

Embodiment 3

[0031] Embodiment 3: Take the deposited SiO with an outer diameter of 60 mm, a single side wall thickness of 22 mm, and a length of 1.8 m. 2 Liner with doped SiO deposited on the inner wall 2 (with GeO 2 etc.), place it on the preform (mandrel) shrinkage equipment;

[0032] Using a graphite heating furnace as a heat source, the axial length of the heating area of the heating element is 350mm, the furnace moves at a speed of 30-35mm / min, the surface temperature of the liner is about 2150-2250°C, and the rotation speed of the quartz liner is 30rad / min;

[0033] When the temperature of the heating element reaches 2100°C, the first melting and shrinkage begins, and the mixed gas (O 2 / C 2 f 6 ), the gas flow is accurately controlled by the flow controller, and the gas pressure at the gas outlet of the liner is controlled at the same time, and it is stabilized within a certain range to ensure a uniform and controllable change in the outer diameter of the mandrel. When the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com