Flat coal machine

A technology of flat coal machine and coal scraper, applied in the field of flat coal machine, can solve the problems of aging automation of loading equipment, purchase and maintenance, high use cost, complex mechanism, etc., and achieves low use and maintenance cost, simple structure, The effect of reducing coal leveling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, the purpose is only to understand the content of the present invention better.

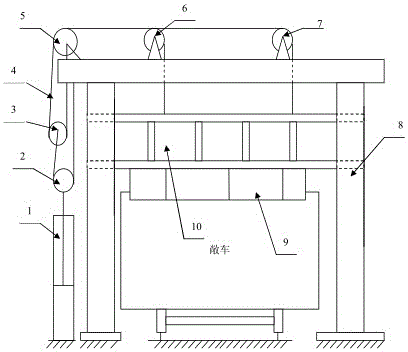

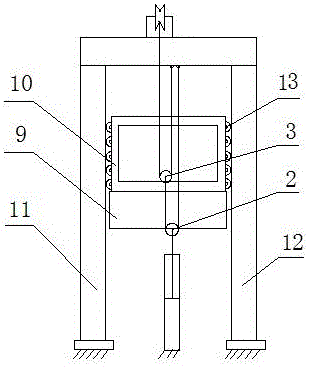

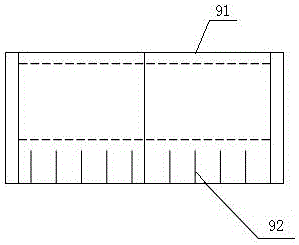

[0018] see figure 1 , figure 2 , the leveling coal machine that present embodiment provides, its gantry 8 adopts seamless steel pipe and channel steel to make, and gantry 8 is fixed on both sides of railway, and lifting frame 10 adopts metal plate or triangular iron to make, and is rectangular parallelepiped structure; Scraping The upper end of the coal plate assembly 9 is fixedly connected to the lower end of the lifting frame 10, the left and right ends of the lifting frame 10 are clamped between the front frame 11 and the rear frame 12 of the gantry frame 8, and the left and right ends of the lifting frame 10 are connected to the gantry The opposite side of frame 8 is provided with rolling roller 13, and the upper end of lifting frame 10 is connected with hoisting device by wire rope 4.

[0019] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com