Coal ground production system train loading method and device

A production system and train technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve problems such as the arrival time mismatch between trains and buffer warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

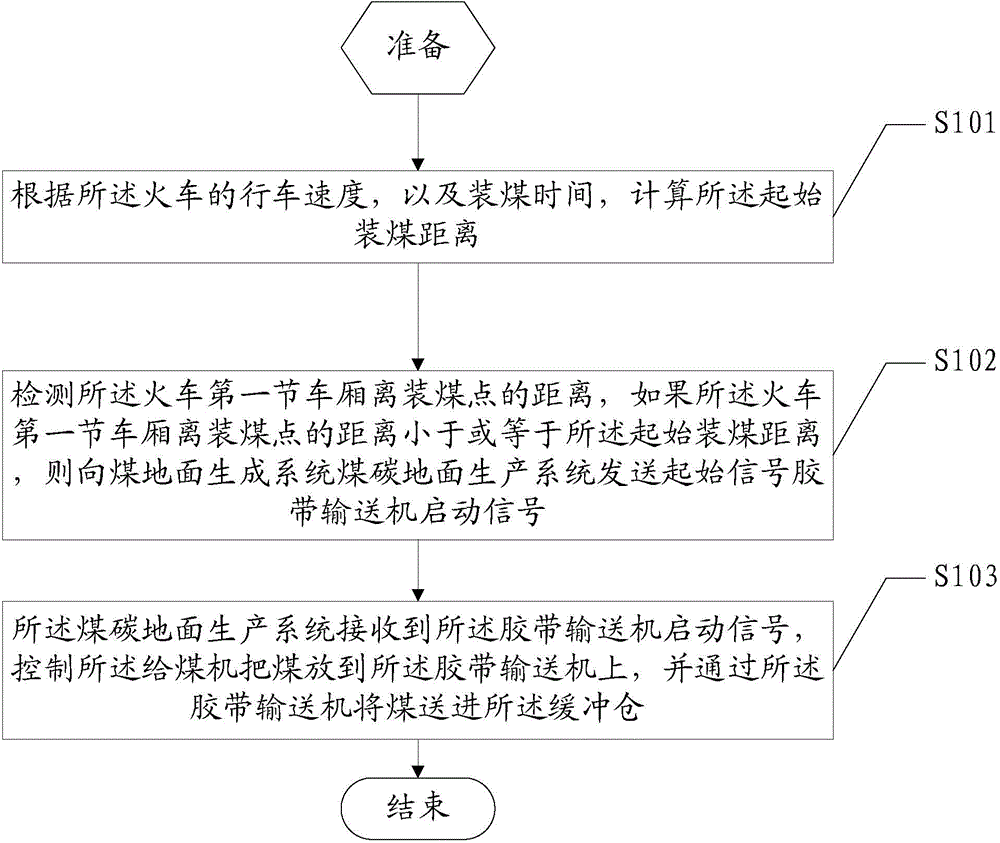

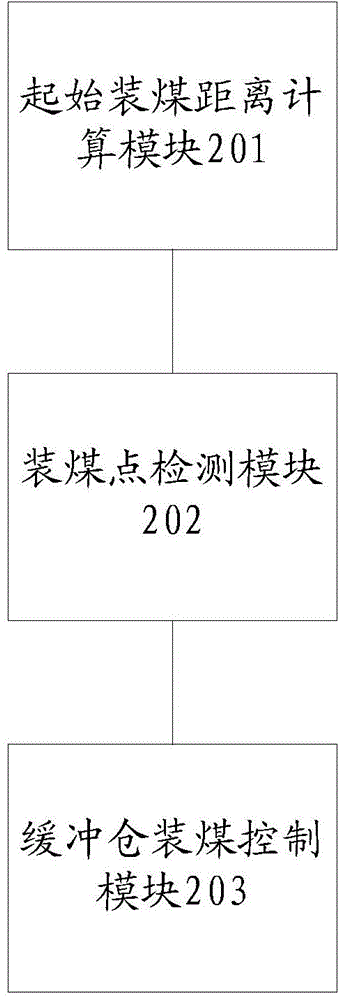

[0017] like figure 1 Shown is a working flow chart of a method for loading trains in a coal surface production system of the present invention, including:

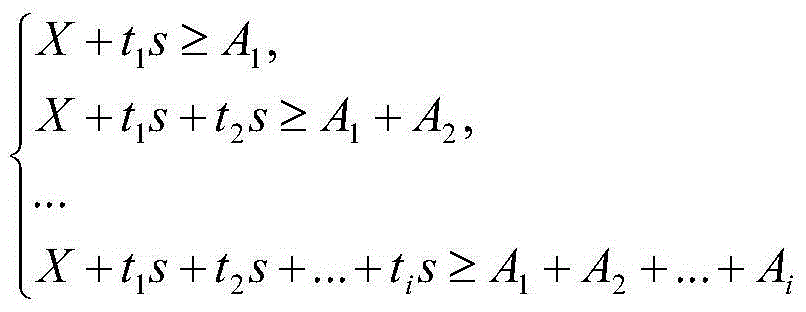

[0018] Step S101, calculate the initial coal loading distance according to the train speed and coal loading time, the initial coal loading distance is the driving speed multiplied by the coal loading time, the coal loading time Put coal on the belt conveyor for multiple coal feeders of the coal ground production system, and send the coal into the buffer bin through the belt conveyor so that the storage position in the buffer bin reaches a reasonable storage position;

[0019] Step S102: Detect the distance between the first car of the train and the coal charging point, if the distance between the first car of the train and the coal charging point is less than or equal to the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com