Method and device for radio frequency identification and parameter configuration of three-dimensional printing consumables

A parameter configuration method and three-dimensional printing technology, which are applied in the field of radio frequency identification and parameter configuration of three-dimensional printing consumables, can solve problems such as overflow of printing materials, affect printing quality, and reduce printing quality, and achieve protection of legitimate rights and interests, reliable identification methods, and improved The effect of print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] The parameters of the 3D printing consumables include the printing parameters of the 3D printing consumables and the auxiliary parameters of the 3D printing consumables, which can be encrypted and stored to further increase the difficulty of counterfeiting the 3D printing consumables.

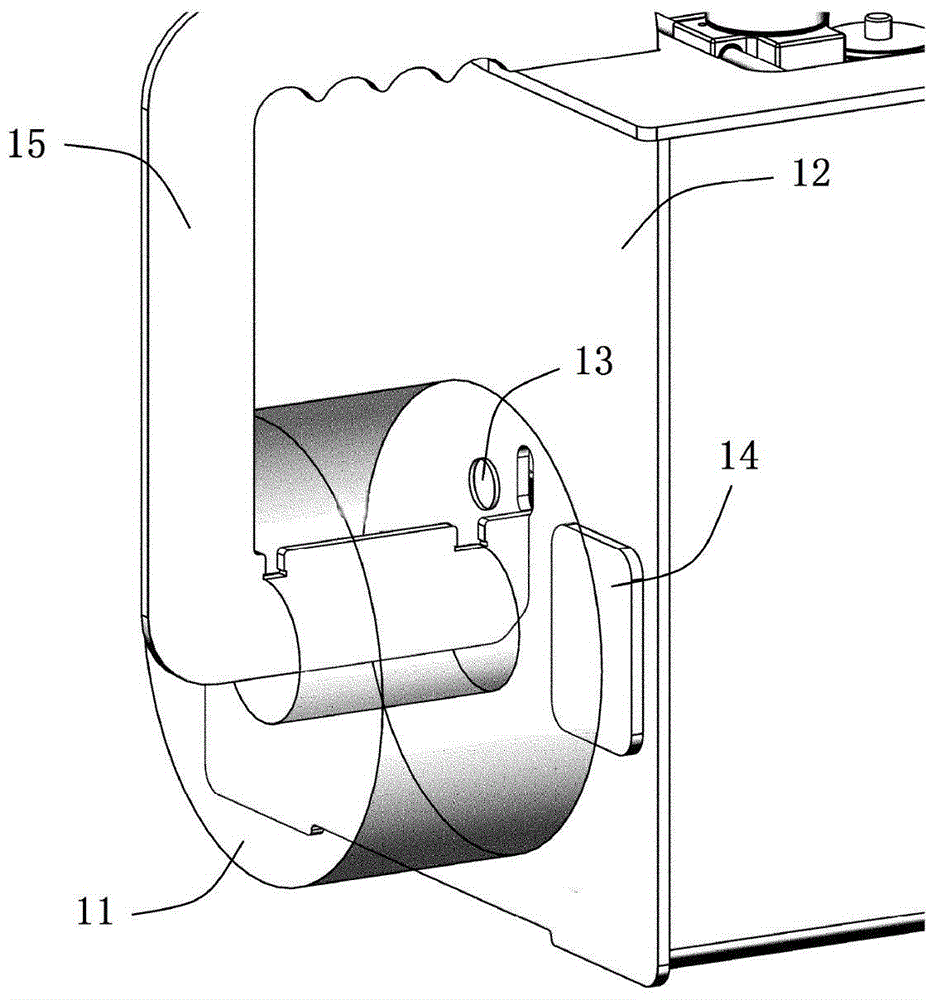

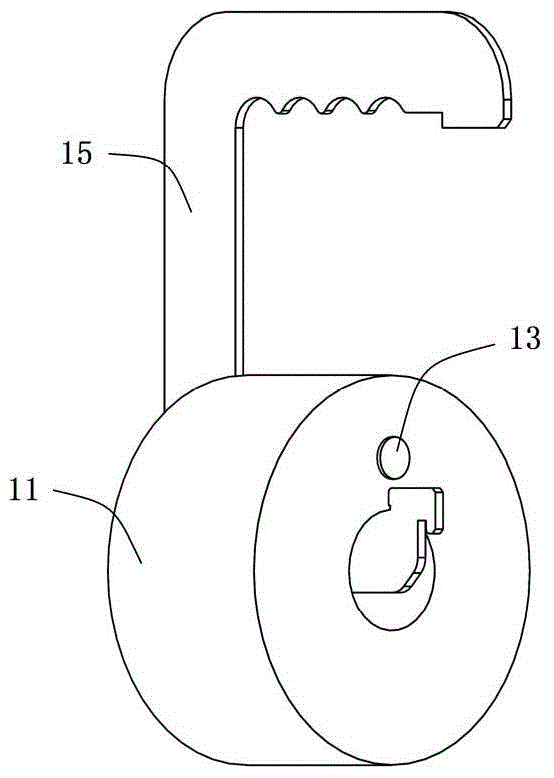

[0037] figure 1 It is a schematic diagram of a 3D printing consumable with an RFID chip and a 3D printer equipped with a corresponding interface device of the present invention. The 3D printing consumables 11 are drawn transparently for clarity of illustration. The 3D printing consumables mounting part 15 is used to hang the 3D printing consumables on the 3D printer 12. The 3D printing consumables 11 are installed on the 3D printer 12 through the 3D printing consumables mounting parts 15. The chip 13 is fixed on the side close to the 3D printer 12 when the 3D p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com