Preparation method of solid catalyst for Knoevenagel reaction

A solid catalyst and catalyst technology, which is applied in the preparation of organic compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of difficult catalyst recovery and high cost, and achieve low production costs, reduced preparation costs, and catalytic activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

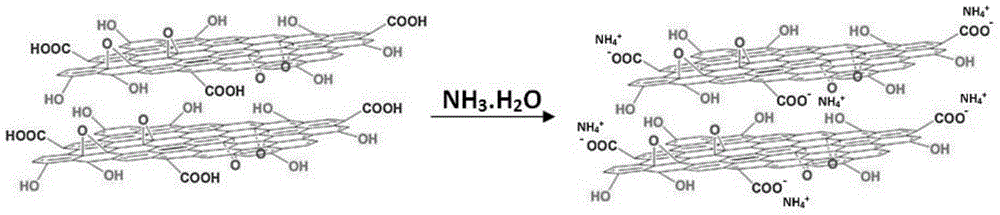

Method used

Image

Examples

Embodiment 1

[0019] Take 0.1g of graphene oxide and put it into 10g of ammonia water, the concentration of ammonia water is 28%, stir vigorously at 20°C for 6h, perform suction filtration after the reaction, wash with deionized water until the filtrate is neutral, and then filter the cake Dry the required catalyst in a vacuum oven at 40°C (10Pa) for 6h, which is designated as Cat1.

Embodiment 2

[0021] Take 0.1g of graphene oxide and put it into 20g of ammonia water, the concentration of ammonia water is 28%, stir vigorously at 20°C for 6h, perform suction filtration after the reaction, wash with deionized water until the filtrate is neutral, and then filter the cake Dry the required catalyst in a vacuum oven at 40°C (10Pa) for 6h, and record it as Cat2.

Embodiment 3

[0023] Take 0.1g of graphene oxide and put it into 15g of ammonia water, the concentration of ammonia water is 28%, stir vigorously at 10°C for 6h, carry out suction filtration after the reaction, wash with deionized water until the filtrate is neutral, then remove the filter cake Dry the required catalyst in a vacuum oven at 40°C (10Pa) for 6h, and record it as Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com