Membrane element, water treatment device and water treatment method

A membrane element and pure water technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of increasing wastewater and reducing scaling, and achieve the goals of prolonging service life, reducing scaling tendency, and reducing scaling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

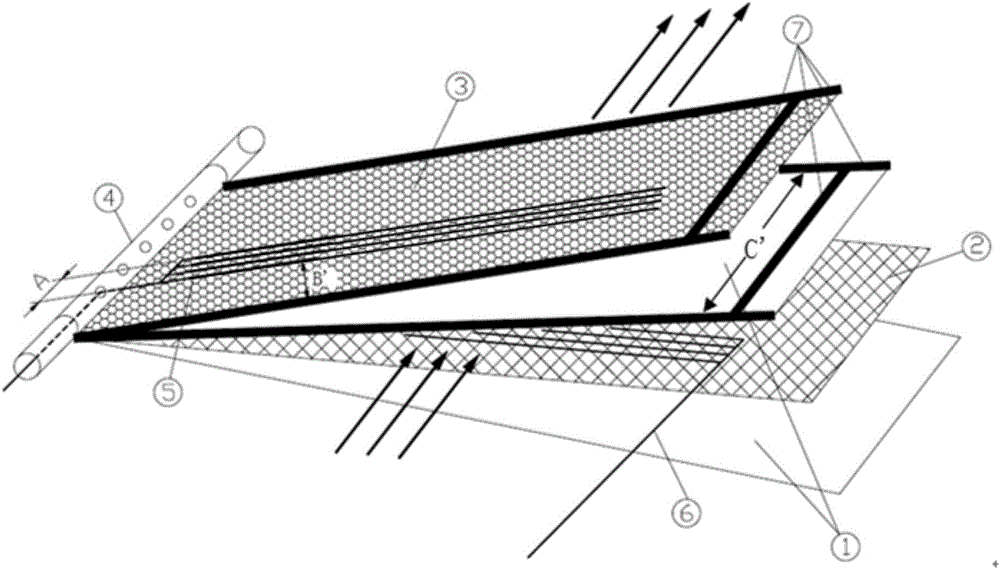

[0051] Add seven 10cm-long 0.5mm-diameter iridium oxide-coated titanium wires as electrodes in the inlet grid of the 1810-75G-ss side-flow type reverse osmosis membrane element (the water inlet direction changes), and the pure water guide cloth Add seven 5cm-long and 0.5mm-diameter iridium oxide-coated titanium wires as electrodes, and the total surface area S of the pure water end electrodes is 5.5cm 2 , the length of each diaphragm is 72.5cm, and the total distance between the electrodes is 15cm. In this example, the long side of the electrode layout area of the pure water end is 15cm long, the long side is perpendicular to the direction of water flow, the short side is 5cm long, and the short side is parallel to the inlet water flow direction. Water flow direction; where A is the length of the short side of the pure water electrode layout area, which is 5cm, B is the distance from the electrode wire closest to the water inlet to the water collection pipe, which is 5cm, and...

Embodiment 2

[0053] Add 7 10cm-long 0.5mm diameter iridium oxide-coated titanium wires as electrodes to the water inlet grid of TW-1812-75G ordinary reverse osmosis membrane element (the water inlet direction does not change), and add 3 wires to the pure water guide cloth 15cm long copper wire with a diameter of 0.25mm is used as the electrode, the length of the water inlet channel is 30cm, and the total distance between the electrodes is 2.5cm. The short side is 2.5cm, parallel to the flow direction of the influent water, where A is 2.5cm, B is 1cm, and C' is 30cm. A new type of roll-type membrane element for controlling membrane fouling is prepared, and the pure water end electrode wire and the negative electrode of the DC power supply The electrode wire at the water inlet is connected to the positive pole of the DC power supply. When the power is on, the tap water is separated by using the new roll-type membrane element that controls membrane fouling. The recovery rate is 33%. When the ...

Embodiment 3

[0055] The preparation method of the roll type membrane element of novel control membrane fouling is as embodiment 1, wherein adds 6 iridium-coated titanium wires of 15cm length in the pure water guiding cloth, under electrification condition, TDS is that the tap water of 160ppm is separated, and the recovery rate Controlled at 50%, when the current is 60-100mA, the pH of the pure water increases from 6.5 to 8.5, and the LSI at the wastewater end decreases to below 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com