Filter core type deduster and control method thereof

A dust collector and filter element technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of easy blockage of the filter device, incomplete dust filtration, troublesome cleaning of the filter device, etc., and achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

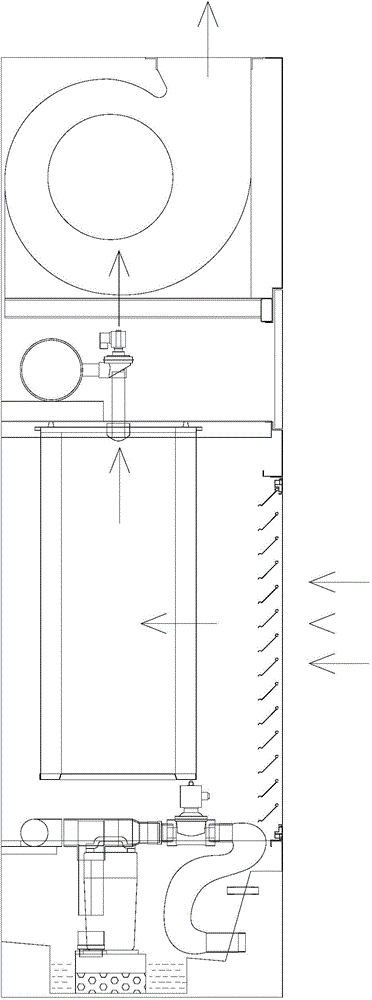

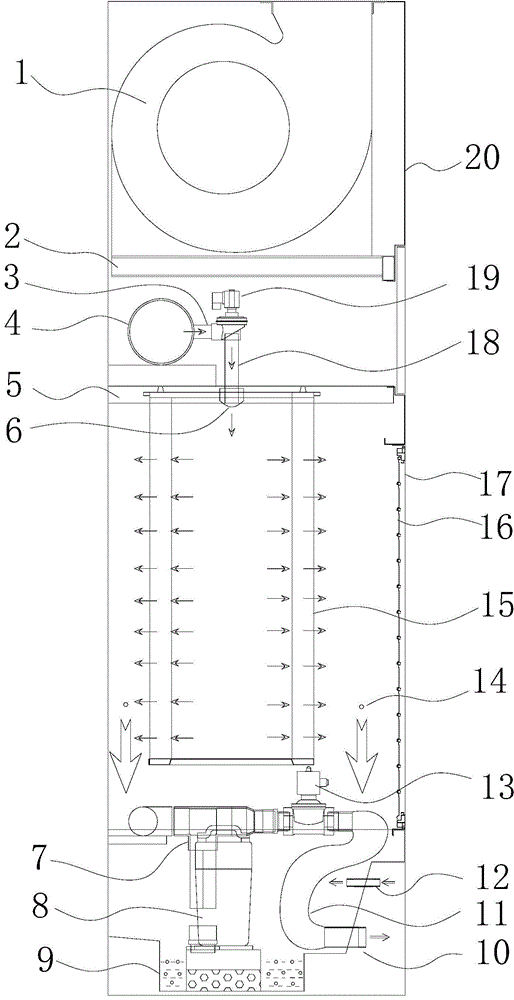

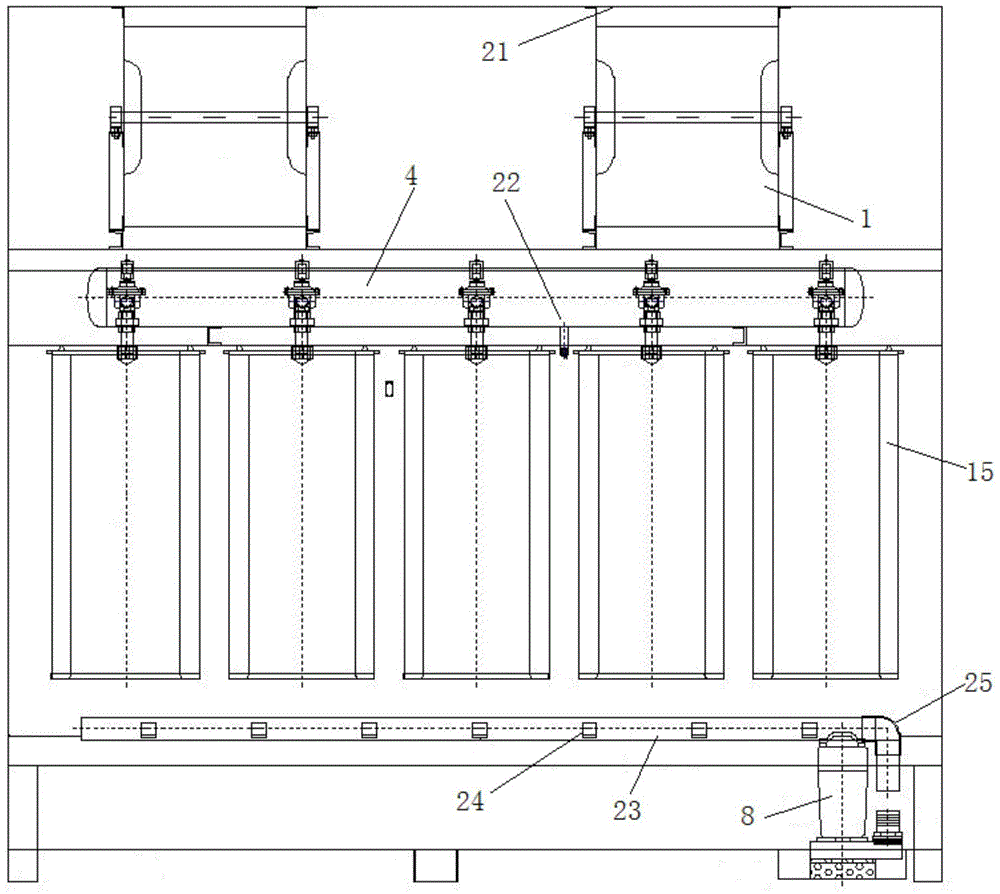

[0032] This embodiment relates to a filter element type dust collector, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a cabinet body 20, a fan 1 and a dirt accumulation tank 9, the fan 1 is arranged on the top of the cabinet body 20 through the fan support plate 2, the top surface of the fan 1 is provided with an air outlet 21, and the dirt accumulation tank 9 is arranged on the cabinet body At the bottom of 20, a filter element 15 is arranged between the blower fan 1 and the dirt tank 9, and a cylindrical porous fiber filter element can be used. The filter element 15 is fixed on the inside of the cabinet 20 by the filter element mounting plate 5, and the bottom end of the filter element 15 is closed. The middle part of the top is provided with a through hole, and the through hole is equipped with a blowing explosion head 6, and the blowing explosion head 6 is connected with a pulse valve 19 through a blowing pipe 18, and the filter element moun...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is: as Figure 5 As shown, the water inlet and outlet are set on the opposite side of the sewage tank, and the height of the water inlet is greater than the height of the water outlet. Firstly, the water inlet is connected to the self-contained water source. , The drain valve is always open, so that after the water entering the dirt tank fully washes the dust, the dust and water form mud and then flow out from the water outlet, realizing the self-circulation flushing of the dirt tank without manual cleaning, which is very convenient. In the case of a production workshop with drainage ditches and sedimentation tanks, the mud can automatically flow to the drainage ditch; in the case of no drainage ditches in the production workshop, the sewage pump can be controlled by one key through the circuit, and it can be directly discharged to the further sedimentation through the pipeline pool.

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is that the dry powder collection type is used to directly recover dust or highly polluted dust, such as Figure 6 As shown, there is no water in the dirt tank at the bottom of the cabinet, and the dust deposited on the outer surface of the filter element falls off and settles in the bottom dirt tank of the cabinet, and then the dust at the bottom can be directly recovered, especially suitable for dust with special properties , such as dust that is likely to cause water pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com