A new energy-saving process of heat pump distillation for desulfurization solvent in renewable flue gas desulfurization

A technology for regenerative flue gas and heat pump distillation, which is applied in steam distillation, sustainable manufacturing/processing, flash evaporation, etc. It can solve problems such as insufficient heat recovery, high material grade requirements, and high operating pressure of reboiler, so as to reduce distillation Effects of energy consumption, improvement of energy utilization rate, and reduction of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

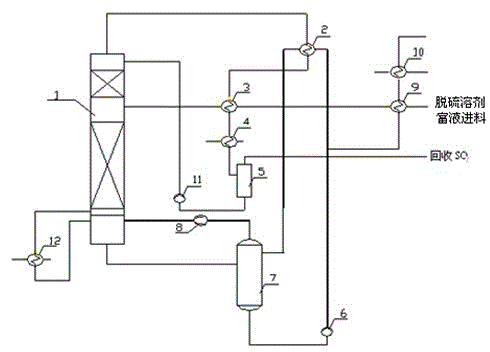

[0038] A new heat pump distillation energy-saving process for desulfurization solvent in renewable flue gas desulfurization, the process steps are as follows:

[0039] A. The self-desulfurization section contains SO2 The rich liquid of the desulfurization solvent is distilled and separated from SO in the distillation tower 2 , the lean liquid at the bottom of the distillation tower is sent to the flash tower, and flashed in the flash tower;

[0040] B. The flash steam generated by flash evaporation is sent into the compressor, and the compressor is used to compress the flash steam to do work;

[0041] C. Send the steam output from the compressor to the bottom of the distillation tower, form the rising steam required for distillation with the vaporized water, and conduct mass transfer and heat transfer with the rich liquid descending from the upper part of the distillation tower to complete the distillation process;

[0042] The part of the lean liquid after flash evaporation ...

Embodiment 2

[0044] A new heat pump distillation energy-saving process for desulfurization solvent in renewable flue gas desulfurization, the process steps are as follows:

[0045] A. The self-desulfurization section contains SO 2 The rich liquid of the desulfurization solvent is distilled and separated from SO in the distillation tower 2 , the lean liquid at the bottom of the distillation tower is sent to the flash tower, and flashed in the flash tower;

[0046] B. The flash steam generated by flash evaporation is sent into the compressor, and the compressor is used to compress the flash steam to do work;

[0047] C. Send the steam output from the compressor to the bottom of the distillation tower, form the rising steam required for distillation with the vaporized water, and conduct mass transfer and heat transfer with the rich liquid descending from the upper part of the distillation tower to complete the distillation process;

[0048] The part of the lean liquid after flash evaporatio...

Embodiment 3

[0050] A new heat pump distillation energy-saving process for desulfurization solvent in renewable flue gas desulfurization, the process steps are as follows:

[0051] A. The self-desulfurization section contains SO 2 The rich liquid of the desulfurization solvent is distilled and separated from SO in the distillation tower 2 , the lean liquid at the bottom of the distillation tower is sent to the flash tower, and flashed in the flash tower;

[0052] B. The flash steam generated by flash evaporation is sent into the compressor, and the compressor is used to compress the flash steam to do work;

[0053] C. Send the steam output from the compressor to the bottom of the distillation tower, form the rising steam required for distillation with the vaporized water, and conduct mass transfer and heat transfer with the rich liquid descending from the upper part of the distillation tower to complete the distillation process;

[0054] The part of the lean liquid after flash evaporatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com