Objective lens frame connector

A technology of frame connectors and objective lenses, which is applied in the field of lithography, can solve problems such as amplifying the influence of disturbances, and achieve the effects of avoiding disturbances, improving connection stability, and reducing response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

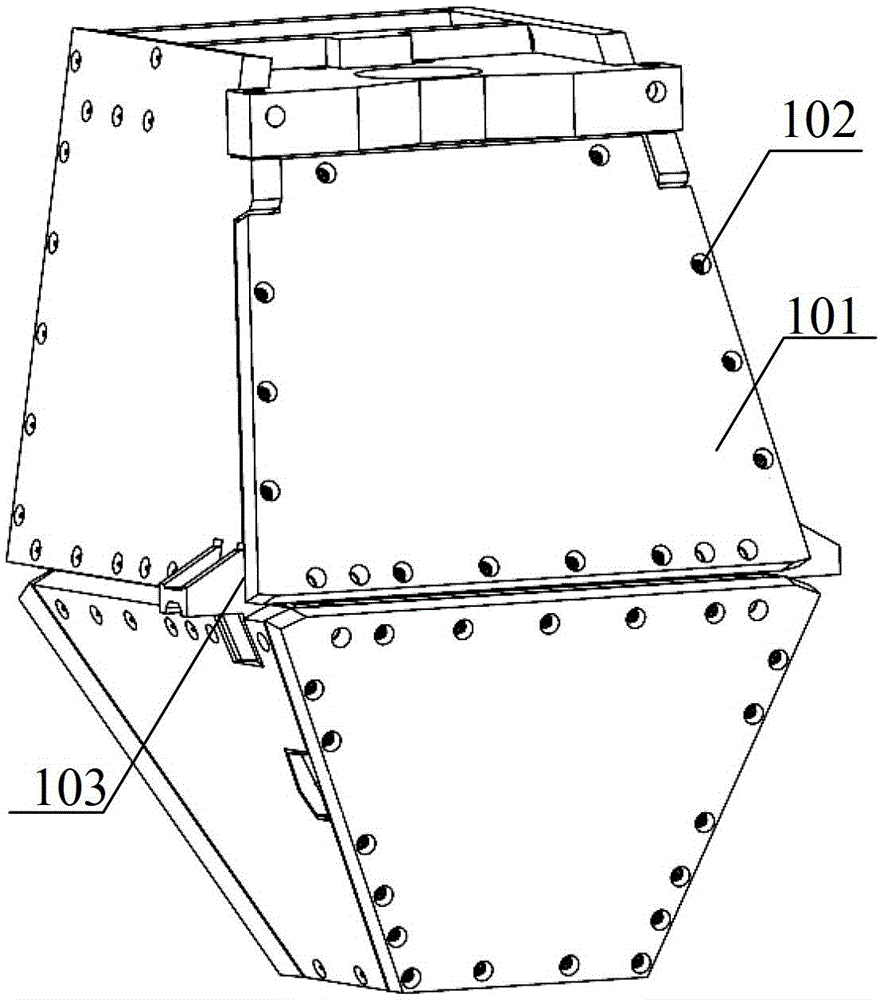

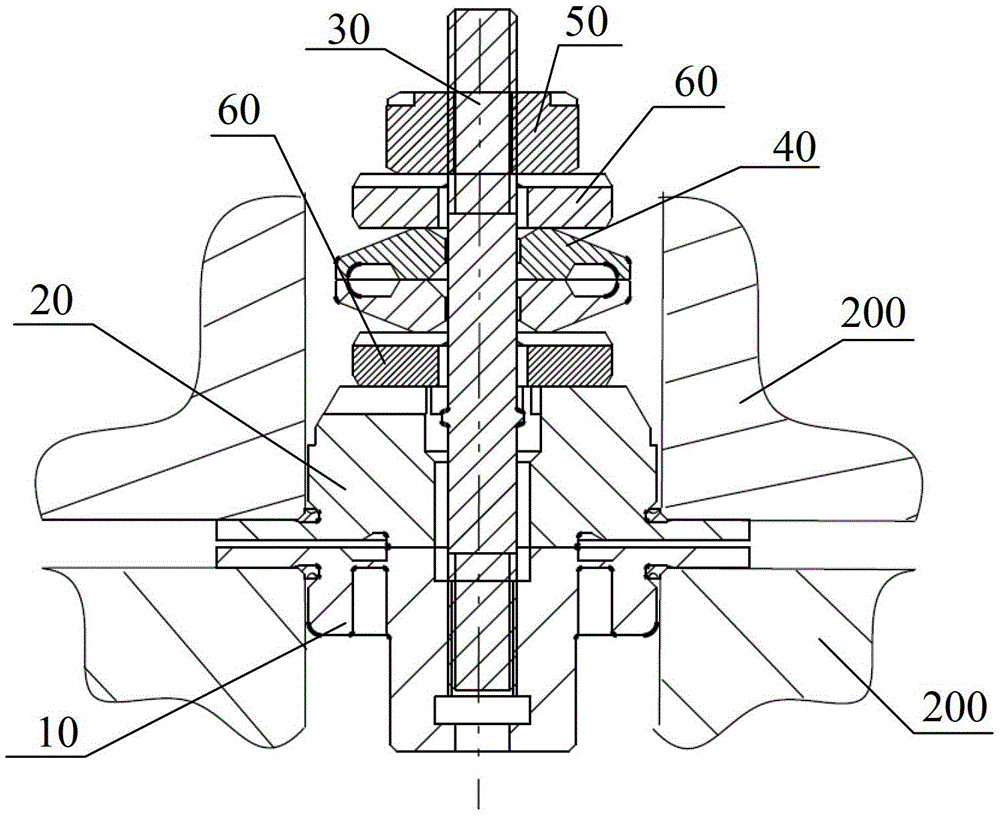

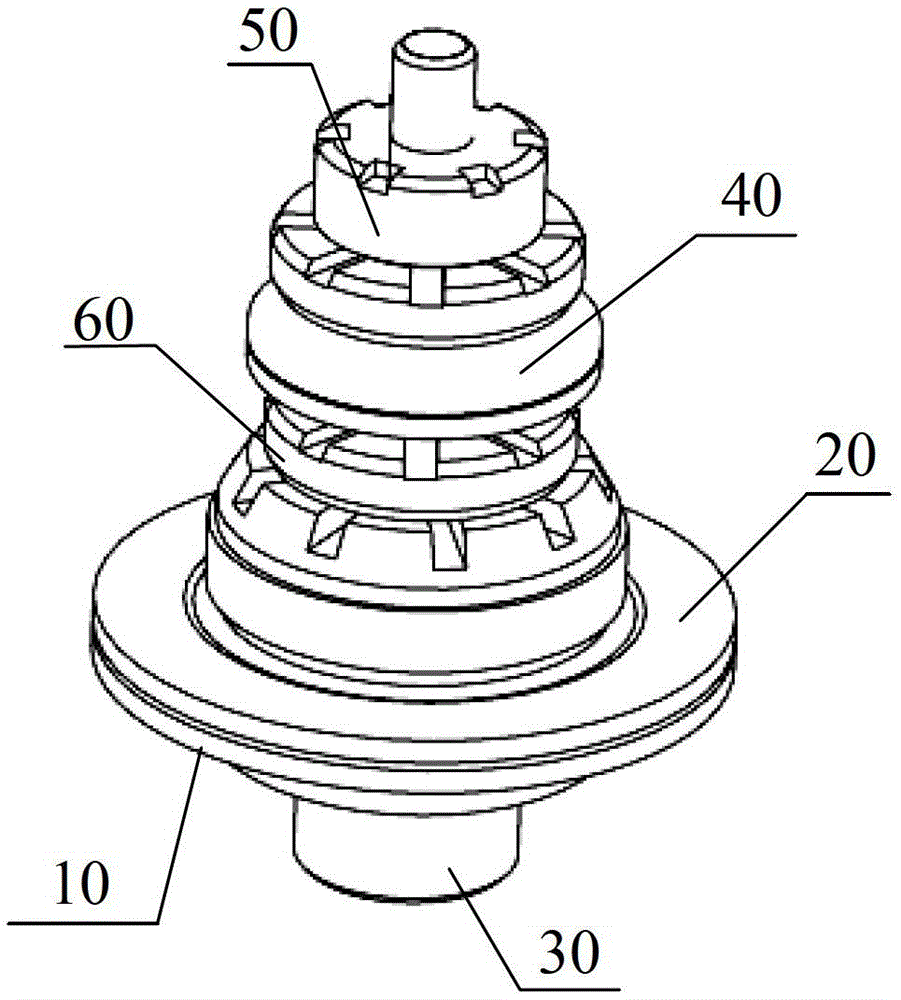

[0032] The objective lens frame connector of the present embodiment, Figure 2-6 As shown, it includes: a flexible base 10 , a flexible cover 20 , stud bolts 30 and butterfly spring sets 40 . Wherein, the flexible base 10 and the flexible cover 20 are connected through the stud bolts 30, and the flexible base 10 and the flexible cover 20 are respectively fixedly connected with the objective lens frame 200, and the butterfly spring group 40 is fixed on the On the above-mentioned stud bolt 30. Specifically, the objective lens frame connector is used for the connection between two objective lens frames 200, the belleville spring group 40 is used to preload the objective lens frame connector, and the stud bolt 30 plays the role of one-way locking, The connection stability of the objective lens frame connector can be improved. Since the studs 30, the flexible base 10 and the flexible cover 20 can be quickly disassembled and installed, each frame surface of the objective lens fram...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 lies in the structure of the flexible upper cover.

[0042] Please refer to Figure 7-8 , the flexible base 10' is provided with a flexible connecting ring 80', and the two sides of the flexible connecting ring 80' are respectively provided with flexible lower grooves 90'. Further, a flexible upper groove 100' is also provided on the flexible cover plate 20'. At this time, the axial stiffness of the objective lens frame connector is higher than the shear stiffness, where the axial (Z’) stiffness is 0.1×10 5 N / mm to 10×10 5 Between N / mm, the shear stiffness (R’) is 0.1×10 5 N / mm to 5×10 5 Between N / mm. Specifically, when the axial width of the flexible connecting ring 80' becomes larger, both the axial and shear stiffnesses become larger, and the axial stiffness is most affected; when the position of the flexible connecting ring 80' is along the shear width The axial stiffness and the shear stiffness are both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com