Urban rail wheel guard rail device and its installation method

A technology of urban rail and installation method, which is applied in the direction of rails, roads, rails, etc., can solve the problems of weak resistance to lateral deformation of the rail frame structure, no device for preventing train wheels from derailing, shortening the service life of rails, etc. The effect of material utilization, easy installation and drilling, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

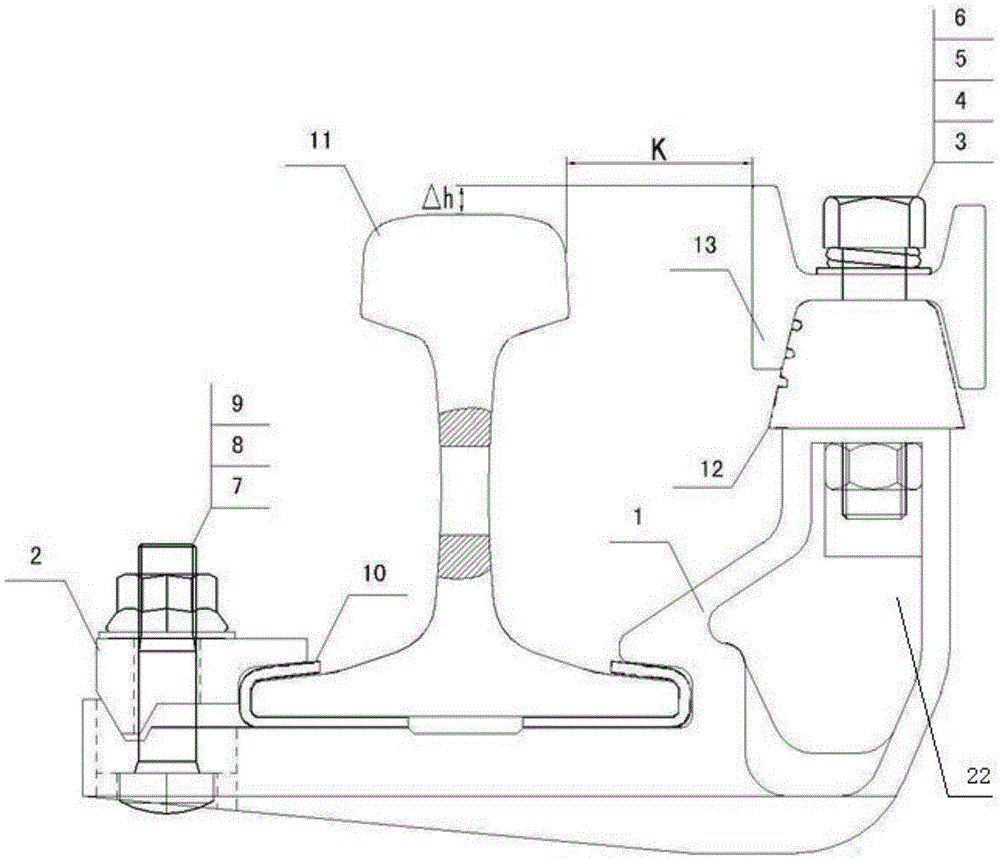

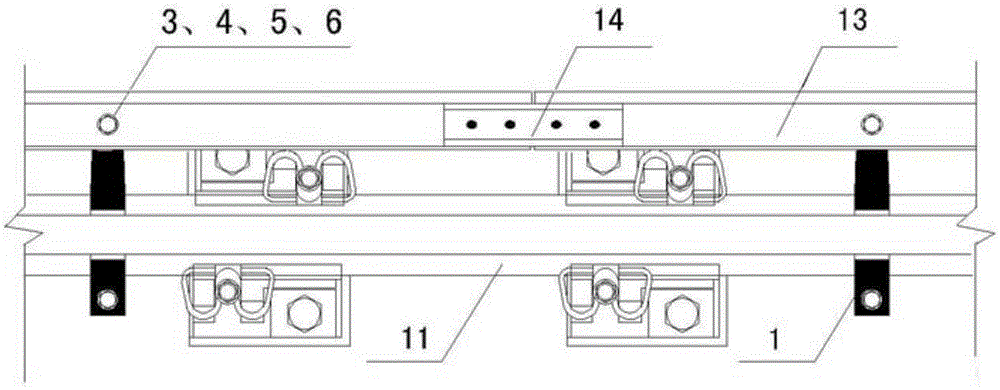

[0038] The present invention will be described in further detail below in conjunction with the drawings.

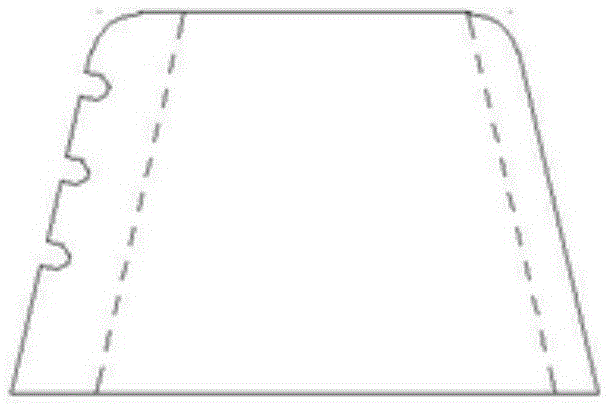

[0039] Such as Figure 1 to Figure 6 As shown, the present invention discloses a new type of urban rail wheel guard rail device, including a guard rail bracket 1, the guard rail bracket 1 is "L" shaped, one end of the guard rail bracket 1 is located under the running rail 11 and is at the bottom of the running rail 11 Fastening connection; the other end of the guard rail bracket 1 is connected to the guard rail 13, the end of the connecting end of the guard rail bracket 1 and the guard rail 13 is covered with a boot type elastic pad 12, the inner surface of the boot type elastic pad 12 and the guard rail The ends of the bracket 1 are in close contact, and the bottom side of the running rail 11 is clamped into the slot of the guard rail bracket 1, and the other side of the rail bottom is pressed by the wedge-shaped buckle plate 2. The wedge-shaped buckle plate 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com