Steel tube concrete support connecting structure and connecting construction method thereof

A technology of concrete filled steel tube and connection structure, which is applied in earthwork drilling, pillar/support, mining equipment, etc., can solve the problems of uneven stress distribution, complicated installation and high production cost, achieve simple operation, reduce impact ground pressure, prevent The effect of buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

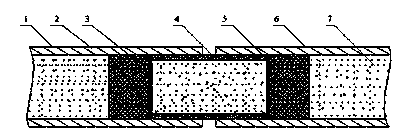

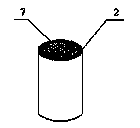

[0023] Such as figure 1 As shown, the connection structure of the steel pipe concrete support is composed of the first section of the steel pipe concrete support (1), the steel pipe (2), the particles (3), the connecting column (4), the steel gasket (5), and the second section of the steel pipe concrete support (6) and concrete core (7), the connecting live column (4) is a steel pipe filled with concrete, and the connecting live column (4) is respectively inserted into the empty pipe section at the end of the first section (1) of the steel tube concrete support, and the steel tube concrete support Empty pipe section at the end of the second section (6). The empty pipe section at the end of the first section (1) of the steel pipe concrete support, the empty pipe section at the end of the second section (6) of the steel pipe concrete support is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com