Novel method for preparing 5-hydroxymethylfurfural and furfural by adopting biomass raw material

A biomass raw material, the technology of hydroxymethyl furfural, applied in the direction of organic chemistry and the like, can solve the problems of complex catalyst preparation, high price and the like, and achieve the effects of good industrialization prospects, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 0.2 g of fructose, 0.2 g of iron phosphate, 10 mL of high-purity water, and 50 mL of THF into a 100 mL autoclave, and react at a speed of 350 r / min and a temperature of 140 °C for 15 min. The product is separated into an aqueous phase and an organic phase using a separatory funnel , the content of reducing sugar in the aqueous phase was measured by DNS method, and the content of 5-HMF in the organic phase was determined by high performance liquid chromatography. The conversion rate of fructose was >99%, the yield of HMF was 71.49%, and the selectivity was 71.58%.

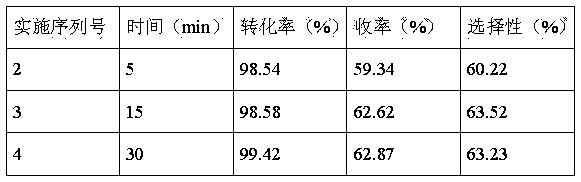

Embodiment 2-4

[0033] Add 0.2 g of fructose, 0.05 g of iron phosphate, 10 mL of high-purity water, and 30 mL of THF into a 100 mL autoclave, and react at a speed of 350 r / min and a temperature of 140 °C for 5, 15, and 30 min respectively, and separate the products using a separatory funnel It is an aqueous phase and an organic phase, the content of reducing sugar in the aqueous phase is measured by DNS method, and the content of 5-HMF in the organic phase is determined by high performance liquid chromatography. The specific reaction results are listed in Table 1.

[0034] Table 1 The conversion rate of fructose at different reaction times, the yield and selectivity of 5-HMF.

[0035]

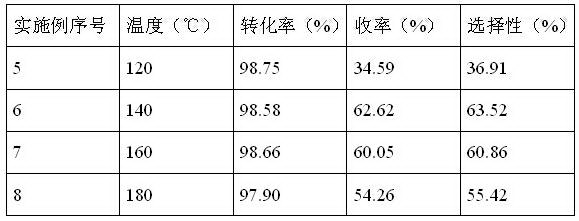

Embodiment 5-8

[0037] Add 0.2 g of fructose, 0.05 g of iron phosphate, 10 mL of high-purity water, and 30 mL of THF into a 100 mL autoclave, and react at 120, 140, 160, and 180 °C for 15 min at a speed of 350 r / min. The separating funnel was separated into water phase and organic phase, the content of reducing sugar in the water phase was measured by DNS method, and the content of 5-HMF in the organic phase was determined by high performance liquid chromatography. The specific reaction results are listed in Table 2.

[0038] Table 2 The conversion rate of fructose, the yield and selectivity of 5-HMF under different reaction temperatures.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com