Concrete contraction-reducing, anti-cracking, water reducing and proofing compacting agent and preparation method thereof

A waterproof compaction and concrete technology, which is applied in the field of concrete shrinkage reduction, crack reduction, water reduction and waterproof compaction agent, can solve the problems of poor effect, complex raw materials and high cost, and can reduce shrinkage, improve impermeability and water reduction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

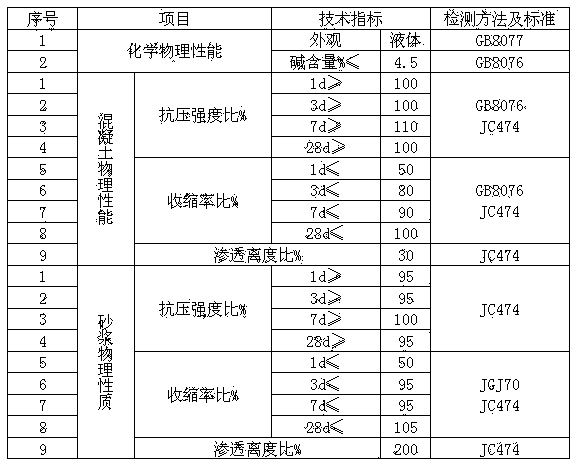

Image

Examples

Embodiment 1

[0020] (1) Raw materials and weight:

[0021] 53 kg of polyether type high-performance polycarboxylic acid water reducing agent with 40% solid content; 15 kg of ferric chloride, 5 kg of sodium gluconate; 3 kg of sucrose; 15 kg of water.

[0022] (Two) production

[0023] Put the ferric chloride into the water first, dissolve it completely in the water under stirring, let it cool naturally, add sodium gluconate and sucrose, and then add the high-performance polycarboxylic acid water reducing agent. According to the above sequence, the raw materials are metered into the container, mixed and stirred until all dissolved, and then entered into the finished product packaging tank, and the packaging is inspected to obtain the product.

Embodiment 2

[0025] (1) Raw materials and weight:

[0026] 52 kg of polyester type high-performance polycarboxylic acid water reducing agent with 40% solid content; 16 kg of ferric chloride; 5 kg of sodium gluconate; 3 kg of sucrose; 15 kg of water.

[0027] (Two) production

[0028] Put the ferric chloride into the water first, dissolve it completely in the water under stirring, let it cool naturally, add sodium gluconate and sucrose, and then add the high-performance polycarboxylic acid water reducing agent. According to the above sequence, the raw materials are metered into the container, mixed and stirred until all dissolved, and then entered into the finished product packaging tank, and the packaging is inspected to obtain the product.

Embodiment 3

[0030] (1) Raw materials and weight:

[0031] 54 kg of polyether type high-performance polycarboxylic acid water reducing agent with 40% solid content; 19 kg of ferric chloride, 9 kg of sodium gluconate; 5 kg of sucrose; 15 kg of water.

[0032] (Two) production

[0033] Put the ferric chloride into the water first, dissolve it completely in the water under stirring, let it cool naturally, add sodium gluconate and sucrose, and then add the high-performance polycarboxylic acid water reducing agent. According to the above sequence, the raw materials are metered into the container, mixed and stirred until all dissolved, and then entered into the finished product packaging tank, and the packaging is inspected to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com