Acid-making sewage treatment system and method

A technology of sewage treatment system and sewage treatment method, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of acid sewage without recycling, waste of metal elements, acid sewage The level of pollution should not be underestimated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

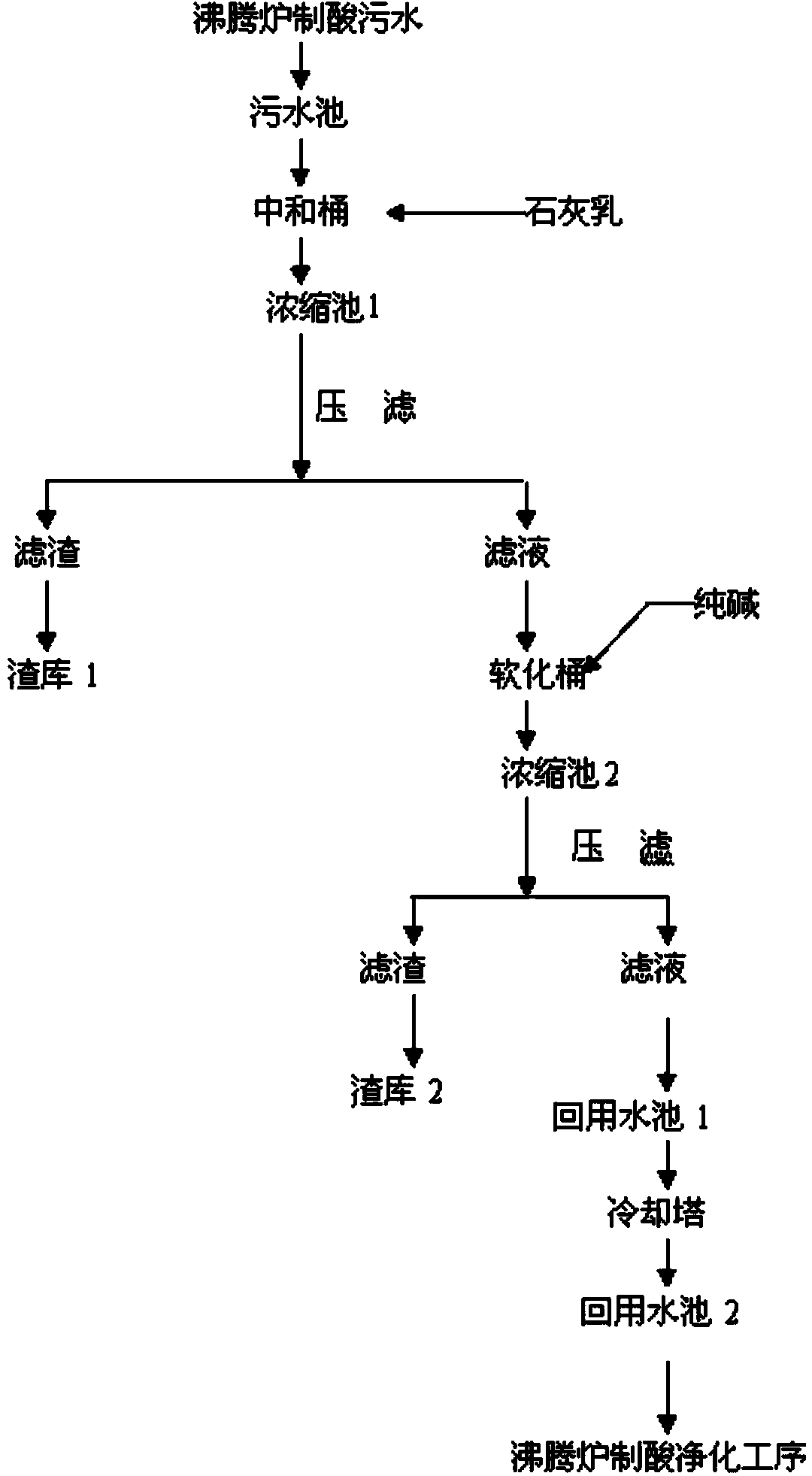

[0068] Pump 600 tons of acid-making sewage in the water inlet tank to the neutralization tank. The hardness of the acid-making sewage is 1000, the pH value is 0.5, and the temperature is 60°C; add lime milk and lime milk to the neutralization tank Ca(OH) in2 The massfraction of is 5%, and described milk of lime will be 9 with the pH value control in the barrel;

[0069] Discharge the sewage generated in the neutralization barrel to the first sewage concentration tank for concentration to obtain the first filtrate and the first waste residue, recycle the first waste residue, transport the first filtrate to the softening barrel, and add industrial soda ash to the softening barrel for about 750kg, control the pH value of the sewage in the neutralization barrel to 8;

[0070] Concentrate the softened sewage through the second sewage concentration tank for 30 minutes to produce a second filtrate and a second waste residue, recover the second waste residue, and transport the second ...

Embodiment 2

[0074] Pump 500 tons of acid-making sewage in the water inlet tank to the neutralization tank. The hardness of the acid-making sewage is 1500, the pH value is 0.5, and the temperature is 58°C; add lime milk and lime milk to the neutralization tank Ca(OH) in 2 The mass fraction is 5%, and the pH value of the sewage in the neutralization barrel is controlled at about 9.5 by the milk of lime;

[0075] Discharge the sewage generated in the neutralization barrel to the first sewage concentration tank for concentration to obtain the first filtrate and the first waste residue, recycle the first waste residue, transport the first filtrate to the softening barrel, and add industrial soda ash to the softening barrel for about 650kg, control the pH value of the sewage in the softening bucket to be around 8.5;

[0076] Concentrate the softened sewage through the second sewage concentration tank for 30 minutes to produce a second filtrate and a second waste residue, recover the second was...

Embodiment 3

[0080] Pump 700 tons of acid-making sewage in the water inlet tank to the neutralization tank. The hardness of the acid-making sewage is 1100, the pH value is 0.5, and the temperature is 61°C; add lime milk to the neutralization tank, and the lime milk Ca(OH) 2 The mass fraction is 5%, and the pH value in the neutralization barrel is controlled at about 9.2 by the milk of lime;

[0081] Discharge the sewage generated after the neutralization tank to the first sewage concentration tank for concentration to obtain the first filtrate and the first waste residue, recycle the first waste residue, and transport the first filtrate to the softening tank in the sewage softening area to soften Add about 850kg of industrial soda ash into the barrel, and control the pH value of the sewage softening zone between 8 and 9;

[0082] Concentrate the softened sewage through the second sewage concentration tank for 30 minutes to produce a second filtrate and a second waste residue, recover the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com