Installation method for integrated prefabrication of anchor platform and anchor mouth

An installation method and integral prefabrication technology, which can be used in transportation and packaging, ship parts, ships, etc., can solve problems such as crane resource shortage, difficult assembly, and unsmooth anchor pulling experiments, so as to improve production efficiency and welding quality. Occupies less resources and is conducive to the effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

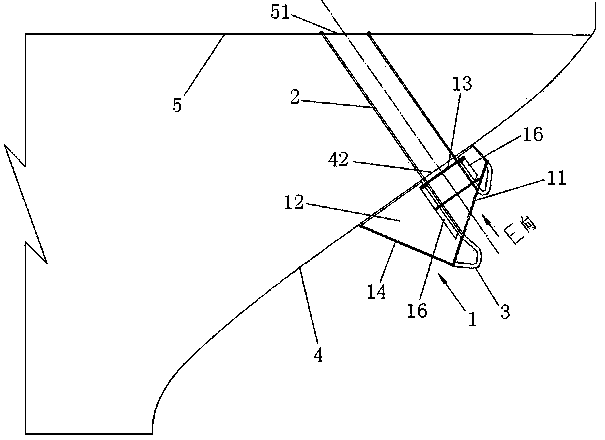

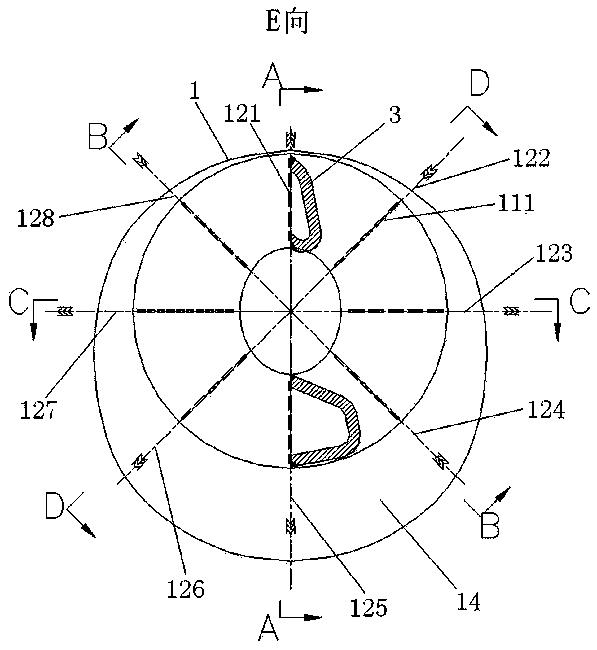

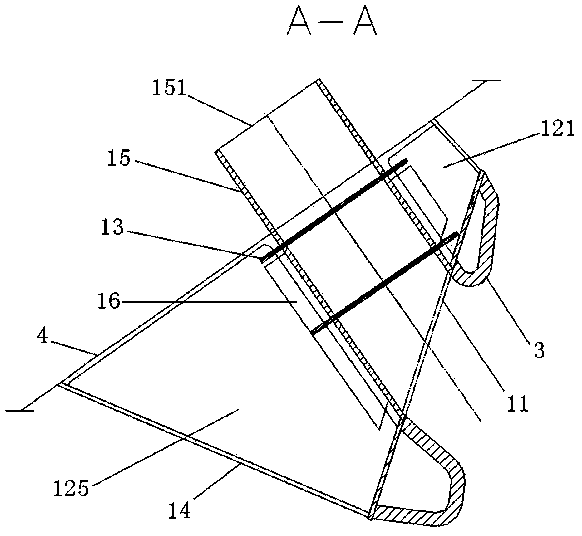

[0032] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] see in conjunction Figure 1-8 As shown, in one embodiment of the present invention, the installation method for the overall prefabrication of the ground of the anchor platform and anchor lip includes the following steps:

[0034] (1) Draw the structural diagram of the anchor platform and its components based on computer-aided drafting, and generate numerical control files to guide the CNC forming system to automatically process the various components of the anchor platform 1. The components include the panel 11, the bracket 12, the ring Connector 13, coaming plate 14, and small-section anchor chain barrel 15; wherein, the panel 11 has intersecting line openings communicating with the small-section anchor chain barrel 15; the brackets 12 are preferably provided with 8 pieces, respectively These are the upper brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com