Method for preparing pure phase bismuth titanate and titanium oxide composite material by using alcohol heat method

A pure-phase bismuth titanate and composite material technology, which is applied in the field of preparation of bismuth titanate-titanium oxide composite materials, can solve the problems of high process requirements and complex synthesis routes, and achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

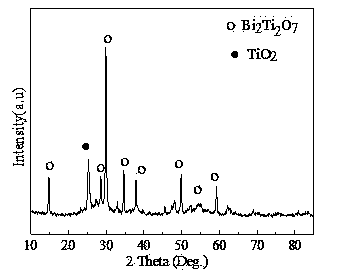

[0029] Mix glycerol and ethanol, stir and mix thoroughly, then add bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixture, stir vigorously for 30 minutes, and then ultrasonically treat the mixture for 15 minutes Transfer to a reaction kettle; the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.2:1; the volume ratio of glycerol and ethanol is 0.05:1. Place the reaction kettle in a constant temperature oven at 120°C to react for 24 hours; after cooling, filter and dry the mixture in the kettle and place it in a temperature-controlled furnace for calcination at 600°C for 3 hours. After cooling, grind the calcined product into a powder with uniform particles. After X-ray diffraction pattern and comparison with cards 04-0477 and 32-0118, it can be confirmed that the obtained sample is Bi 2 Ti 2 o 7 / TiO 2 composite material.

[0030] figure 1 It is the X-ray diffraction spectrum of the sample prepared in embodiment 1, can ...

Embodiment 2

[0032] Mix glycerol and ethanol, stir and mix thoroughly, then add bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixture, stir vigorously for 30 minutes, and then ultrasonically treat the mixture for 15 minutes Transfer to a reaction kettle; the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.2:1; the volume ratio of glycerol and ethanol is 0.1:1. Place the reaction kettle in a constant temperature oven at 120°C to react for 24 hours; after cooling, filter and dry the mixture in the kettle and place it in a temperature-controlled furnace for calcination at 600°C for 3 hours. After cooling, grind the calcined product into a powder with uniform particles. After X-ray diffraction pattern and comparison with cards 04-0477 and 32-0118, it can be confirmed that the obtained sample is Bi 2 Ti 2 o 7 / TiO 2 composite material.

[0033] image 3 It is the X-ray diffraction spectrum of the prepared sample of embodiment 2, can d...

Embodiment 3

[0035] Mix glycerol and ethanol, stir and mix thoroughly, then add bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixture, stir vigorously for 30 minutes, and then ultrasonically treat the mixture for 15 minutes Transfer to a reaction kettle; the molar ratio of bismuth nitrate and tetrabutyl titanate is 0.2:1; the volume ratio of glycerol and ethanol is 0.2:1. Place the reaction kettle in a constant temperature oven at 120°C to react for 24 hours; after cooling, filter and dry the mixture in the kettle and place it in a temperature-programmed furnace for calcination at 500°C for 3 hours. After cooling, grind the calcined product into a powder with uniform particles. After the X-ray diffraction pattern and comparison with the cards JCPDS04-0477 and 32-202, it can be determined that the obtained sample is Bi 20 TiO 32 / TiO 2 composite material.

[0036] Figure 5 It is the X-ray diffraction spectrum of the sample prepared in embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com