Microwave organic modified particle bentonite/attapulgite adsorbent and preparation method thereof

A technology of attapulgite and bentonite, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the problems of secondary pollution, short ion exchange reaction time, etc., to increase strength and shorten modification time , Improve the effect of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

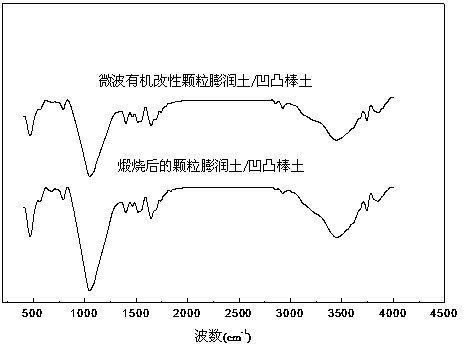

Image

Examples

Embodiment 1

[0027] A microwave organically modified granular bentonite / attapulgite adsorbent and a preparation method thereof. Its specific steps are:

[0028] Step 1, using bentonite powder and attapulgite powder as raw materials, mixing to obtain powdery bentonite / attapulgite; then adding water to the powdery bentonite / attapulgite, and mixing evenly to obtain muddy lump bentonite / attapulgite; Then, the mud-shaped bentonite / attapulgite is dried at 100-110° C. for 16-18 hours to obtain the block-shaped bentonite / attapulgite.

[0029] Among them: the mass ratio of bentonite powder:attapulgite powder is 1:(0.3~0.4); the mass ratio of powdered bentonite / attapulgite:water is 1:(1.2~1.4).

[0030] Step 2, crushing the massive bentonite / attapulgite to a particle size of 0.2-0.45mm to obtain granular bentonite / attapulgite, and then calcining the granular bentonite / attapulgite at 720-780°C for 2~ After 2.5 hours, calcined granular bentonite / attapulgite was obtained.

[0031] Step 3. Dissolve c...

Embodiment 2

[0035] A microwave organically modified granular bentonite / attapulgite adsorbent and a preparation method thereof. Its specific steps are:

[0036] Step 1, using bentonite powder and attapulgite powder as raw materials, mixing to obtain powdery bentonite / attapulgite; then adding water to the powdery bentonite / attapulgite, and mixing evenly to obtain muddy lump bentonite / attapulgite; Then, the mud-shaped bentonite / attapulgite is dried for 18-20 hours under the condition of 100-110° C. to obtain the block-shaped bentonite / attapulgite.

[0037] Among them: the mass ratio of bentonite powder:attapulgite powder is 1:(0.4~0.5); the mass ratio of powdered bentonite / attapulgite:water is 1:(1.4~1.6).

[0038] Step 2, crushing the massive bentonite / attapulgite to a particle size of 0.45~0.9mm to obtain granular bentonite / attapulgite, and then calcining the granular bentonite / attapulgite at 720~780°C for 2~ After 2.5 hours, calcined granular bentonite / attapulgite was obtained.

[0039...

Embodiment 3

[0043] A microwave organically modified granular bentonite / attapulgite adsorbent and a preparation method thereof. Its specific steps are:

[0044] Step 1, using bentonite powder and attapulgite powder as raw materials, mixing to obtain powdery bentonite / attapulgite; then adding water to the powdery bentonite / attapulgite, and mixing evenly to obtain muddy lump bentonite / attapulgite; Then, the mud-shaped bentonite / attapulgite is dried for 20-22 hours under the condition of 100-110° C. to obtain the block-shaped bentonite / attapulgite.

[0045] Among them: the mass ratio of bentonite powder:attapulgite powder is 1:(0.3~0.4); the mass ratio of powdered bentonite / attapulgite:water is 1:(1.8~2).

[0046] Step 2, crushing the massive bentonite / attapulgite to a particle size of 0.45~0.9mm to obtain granular bentonite / attapulgite, and then calcining the granular bentonite / attapulgite at 720~780°C for 2~ After 2.5 hours, calcined granular bentonite / attapulgite was obtained.

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com