Pneumatic blockage-preventing and seed-leakage-free plug seedling and precision seed arrangement method and device

A plug seedling raising and anti-clogging technology, which is applied in the direction of interval quantitative sowing machinery, seeding, planter parts, etc., can solve the problems of easily damaged seeds, and can not be instant without leaking seeds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

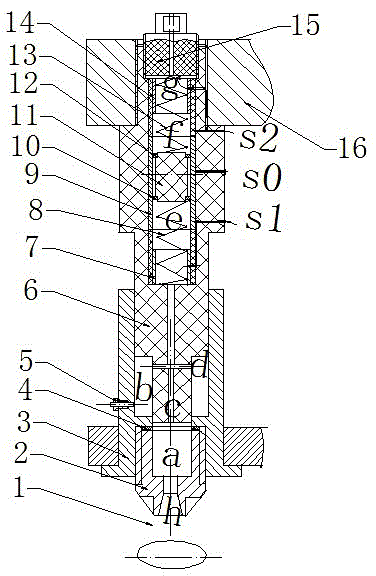

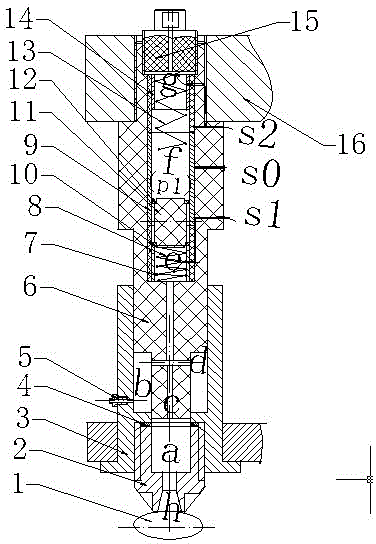

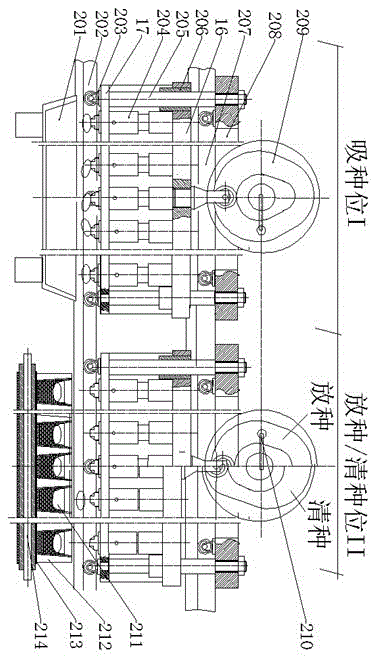

[0042] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] An anti-clogging and non-leaking pneumatic seedling seedling precision seeding method and device, including a multi-suction nozzle suction assembly, a multi-suction nozzle suction assembly transmission system, a seeding frame, a seed tray and its electromagnetic vibrator, and a seedling hole Plate, seedling tray transmission system, air pump and pneumatic circuit, PLC control system, LED light-emitting diode display system, cam clearing device, etc. In order to ensure the detection of no leakage and blockage, each suction nozzle in the multi-nozzle suction assembly is designed as an independent seed suction unit, and each suction unit is equipped with an anti-blockage and leakage prevention device. The piston block detection switch, and the piston block detection switch controls the operation of the multi-nozzle suction assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com