Polycarbonate resin composition and molded body thereof

A technology of polycarbonate resin and composition, which is applied in the field of polycarbonate resin composition, can solve the problems of peeling of resin composition and uneven gloss of molded products, achieve excellent impact resistance, less uneven gloss, and improve compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~5

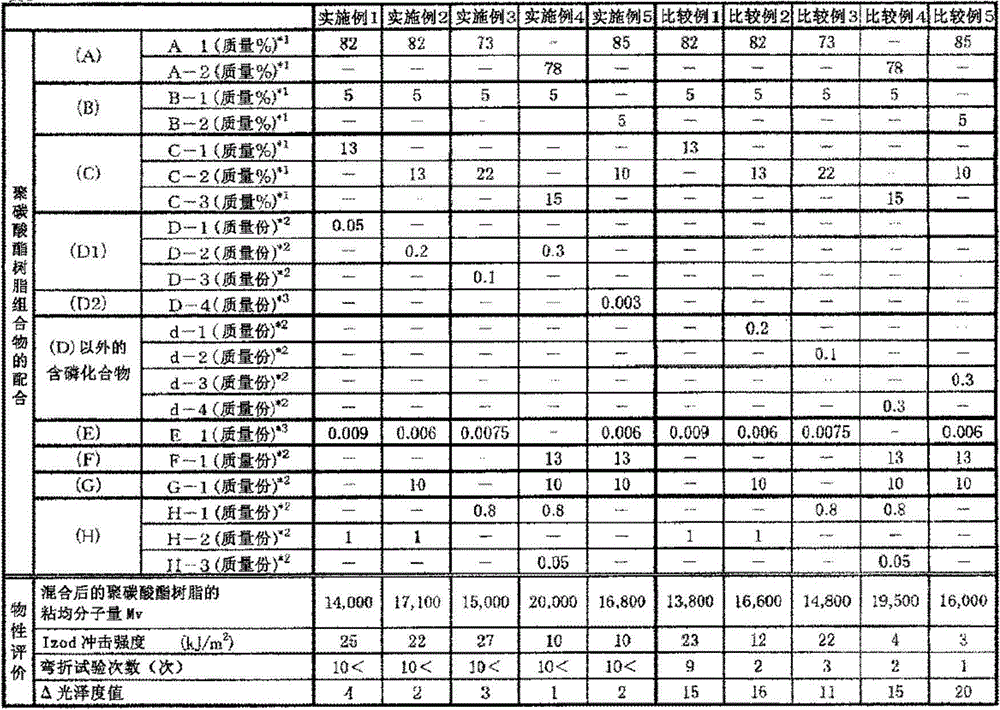

[0189] The resin composition was blended in the blending ratio shown in Table 1 to produce pellets, and the preparation of test pieces and evaluation of physical properties were performed by the above-mentioned method. Table 1 shows the obtained results.

[0190] [Table 1]

[0191] Table 1

[0192]

[0193] (quality%) *1 : % by mass in the total amount of components (A), (B) and (C)

[0194] (parts by mass) *2 : Parts by mass relative to 100 parts by mass of the total amount of components (A), (B) and (C)

[0195] (parts by mass) *3 : Parts by mass of active ingredients relative to 100 parts by mass of the total amount of components (A), (B) and (C)

[0196] As can be seen from Table 1, molded articles obtained from the polycarbonate resin composition of the present invention are superior in impact resistance compared to respective corresponding comparative examples, and even in the case of thin molded articles having film gates, they are There was no layered peeling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com