CLC constant current network led self-balanced current circuit and its control method

A self-leveling, network-type technology, applied in the direction of lamp circuit layout, electric light source, lighting devices, etc., can solve the problems of low voltage utilization, increased reactive power circulation, difficult to improve the efficiency of LED drivers, etc., to reduce the size of the device effects of stress, reduced component count, improved voltage utilization and converter efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

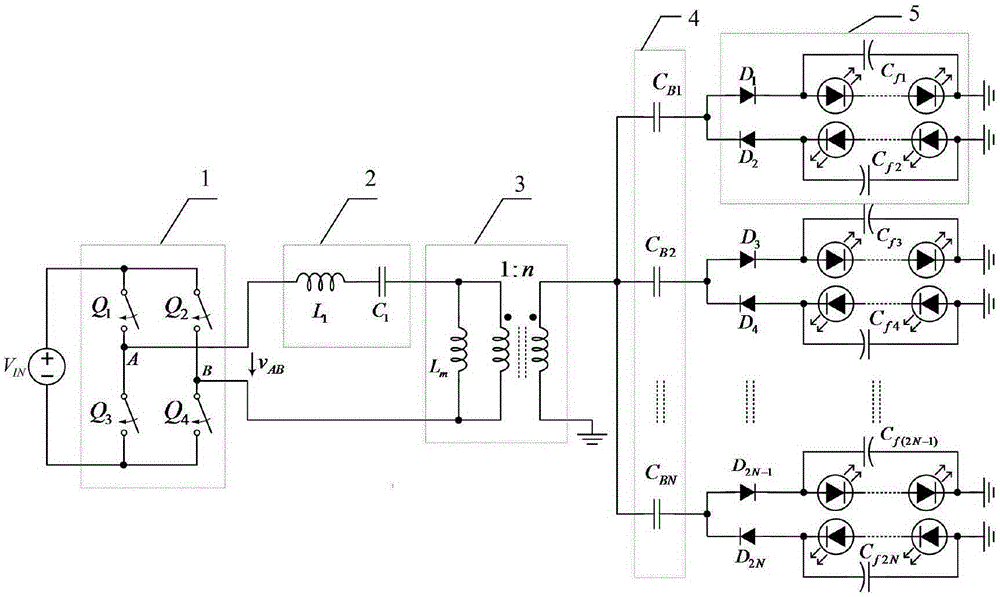

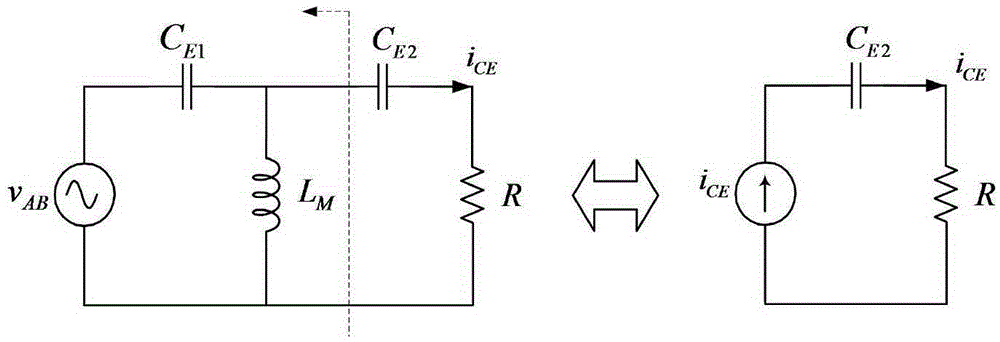

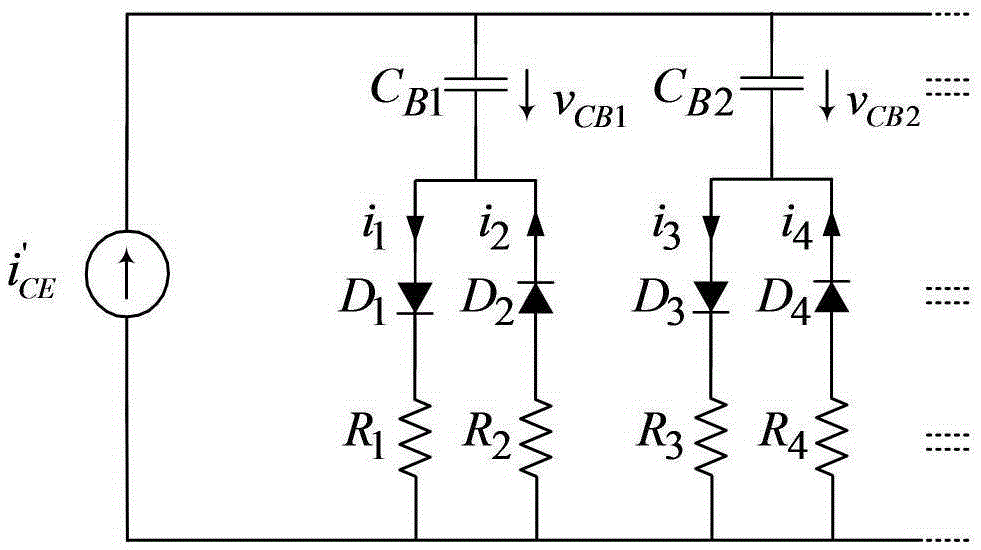

[0034] The present invention is further described in detail below in conjunction with the accompanying drawings of the description: the LED self-balancing circuit of the CLC constant current network structure includes a full-bridge inverter circuit 1, an LC resonance branch 2 that presents capacitive impedance at the resonant frequency point, and a transformation ratio 1:n high-frequency transformer 3, N only current sharing capacitor C B1 、C B2 ,...,C BN A current sharing capacitor unit 4 and N LED output modules 5 are formed. The LC resonance branch 2 presenting capacitive impedance at the resonance frequency point, the high frequency transformer 3 and the current sharing capacitor unit 4 form a CLC constant current network structure. The full-bridge inverter circuit 1 includes: a power switch tube Q 1 , Q 3 The bridge arm (the midpoint of the bridge arm is A), Q 2 , Q 4 The composed bridge arm (the midpoint of the bridge arm is B). There is a primary excitation induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com