A line-selecting annular cavity for chemical laser devices

A chemical laser and ring cavity technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as high threshold, poor beam quality, and large noise, and achieve low threshold, reduce optical loss, and beam quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

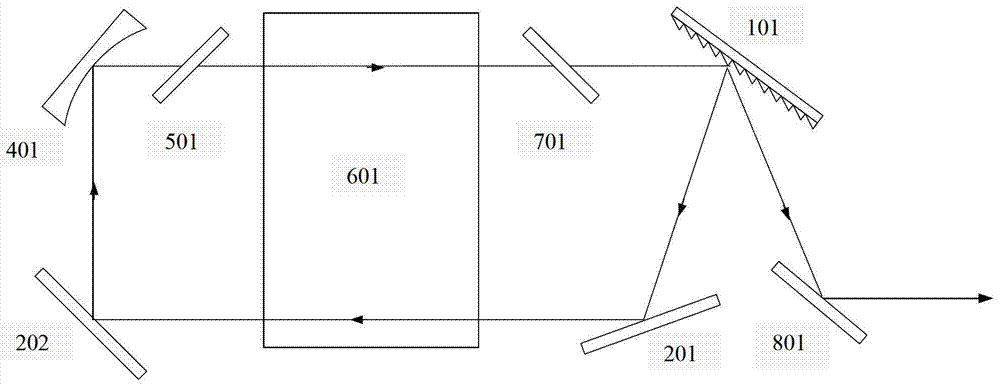

[0032] as attached figure 1 As shown, the structure of the line-selecting four-mirror rectangular cavity used in the chemical laser device of the present invention includes: a gain medium region 601, a Brewster plate I 701, a blazed grating 101, two plane mirrors 201, 202, and a plano-concave mirror 401, Brewster sheet II 501, plane mirror III 801.

[0033] The blazed grating 101 is placed on a motorized turntable, and its diffraction angle is adjusted to the diffraction angle corresponding to the line selection wavelength. When the laser is working, the activated medium in the gain medium region 601 produced by the chemical reaction produces stimulated radiation light of different wavelengths, and these radiation lights pass through the Brewster plate I701 and become linearly polarized light whose vibration direction is parallel to the incident plane. When these linearly polarized lights are incident on the blazed grating 101, the radiated light meeting the first-order diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com