Lithium niobate photomodulator and manufacturing and packaging method thereof

A technology of optical modulator and packaging method, which is applied in the direction of light guide, optics, instrument, etc., can solve the problems of complex preparation process and large size of lithium niobate waveguide chip, and achieve the effects of simplifying the process, enhancing the photoelectric effect, and optimizing the optical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

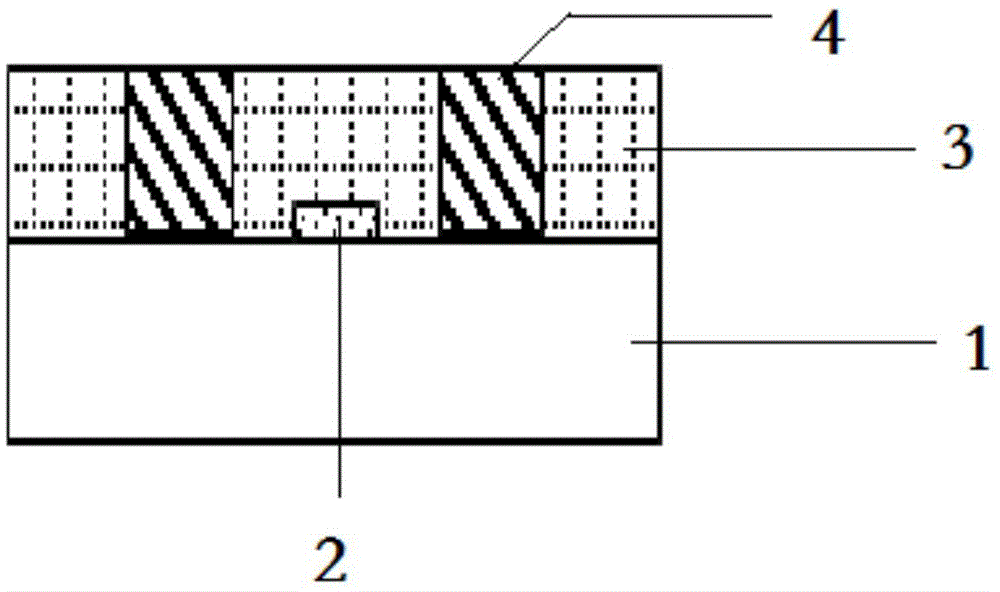

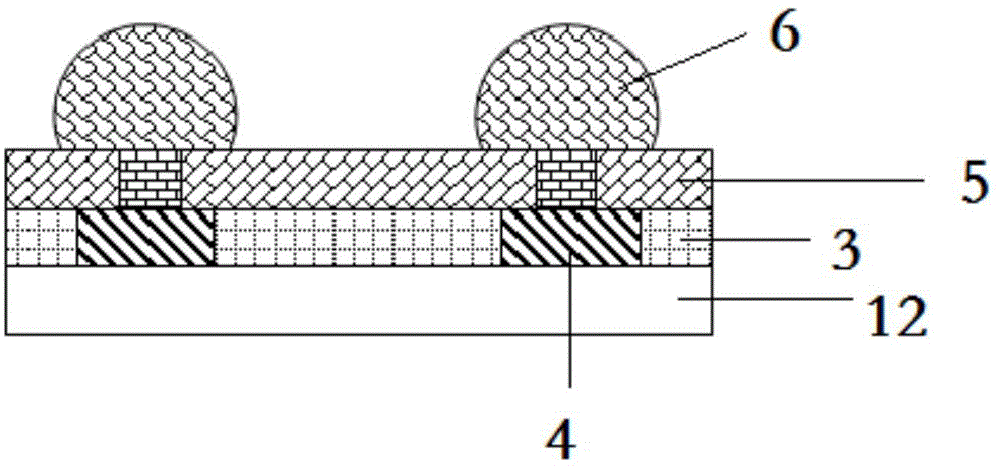

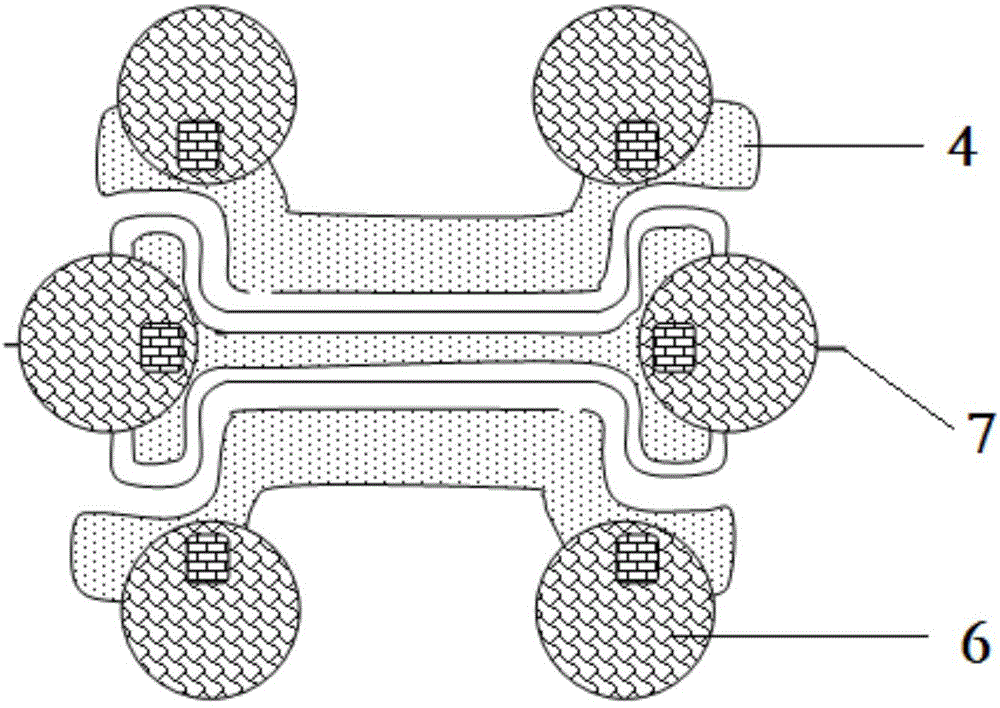

[0044] The lithium niobate optical modulator described in this embodiment will be described in detail below with reference to the accompanying drawings. like figure 1 , figure 2 and image 3 As shown, the lithium niobate optical modulator described in this embodiment includes a waveguide chip, a protective material 5 coated on the upper end of the waveguide chip, and a waveguide 7 connected to an external optical fiber; the waveguide chip includes a lithium niobate substrate 1, and an amorphous silicon layer 2, a silicon dioxide layer 3, and a metal electrode 4 sequentially arranged on the lithium niobate substrate 1; wherein, the thickness of the amorphous silicon layer 2 is smaller than that of the lithium niobate substrate 1 thickness, the lithium niobate substrate 1 and the amorphous silicon layer 2 together form a waveguide 12; an electrode filling area is formed on the silicon dioxide layer 3, and the metal electrode 4 is arranged in the electrode filling area ; The ...

Embodiment 2

[0052] A preparation method of a lithium niobate optical modulator described in this embodiment, such as Figure 5 shown, including the following steps:

[0053] S1: Depositing a layer of amorphous silicon material on the surface of the lithium niobate substrate to form an amorphous silicon layer, the thickness of the amorphous silicon layer being smaller than the thickness of the lithium niobate substrate;

[0054] S2: performing photolithography development and etching stripping on the amorphous silicon layer to form a waveguide;

[0055] S3: Depositing a layer of silicon dioxide on the waveguide to form a silicon dioxide layer;

[0056] S4: Etching on the silicon dioxide layer to obtain electrode filling regions;

[0057] S5: filling the electrode filling area with metal to form a metal electrode.

[0058] In this embodiment, amorphous silicon is selected as a high refractive index material to form a waveguide formed on a lithium niobate substrate. The refractive index ...

Embodiment 3

[0073] This embodiment is based on the packaging method of a lithium niobate optical modulator described in Embodiment 1, comprising the following steps:

[0074] coating a protective material on the waveguide chip;

[0075] providing a protective structure on the outer surface of the protective material on the metal electrode;

[0076] Wrap insulating material on the waveguide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com