Rectangular-waveguide TM11-mode microwave high-power ribbon electron beam collector

A rectangular waveguide, TM11 technology, applied in the high-power microwave field, achieves the effect of insensitivity to structural parameters, high passing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, structure of the present invention and working principle are specifically described:

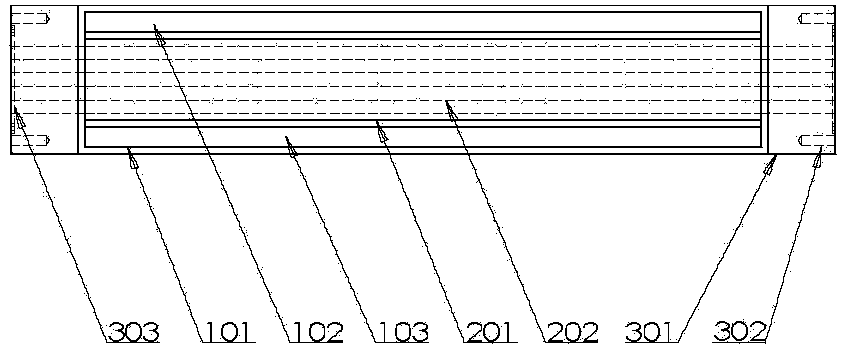

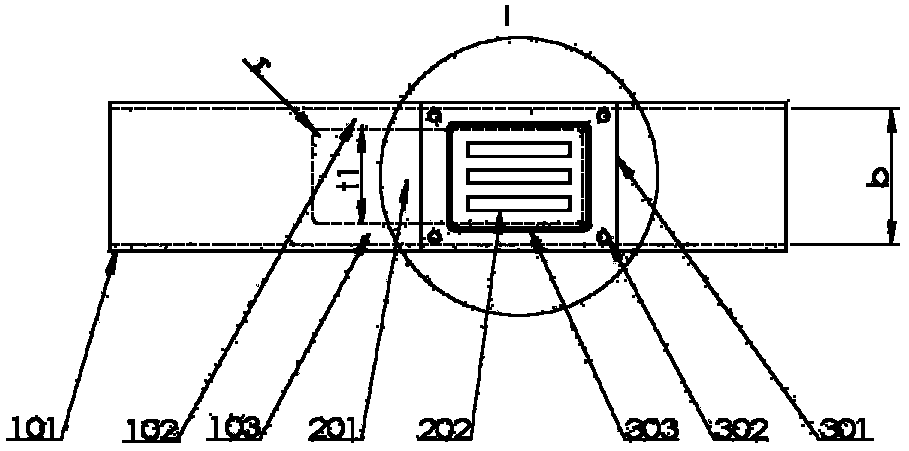

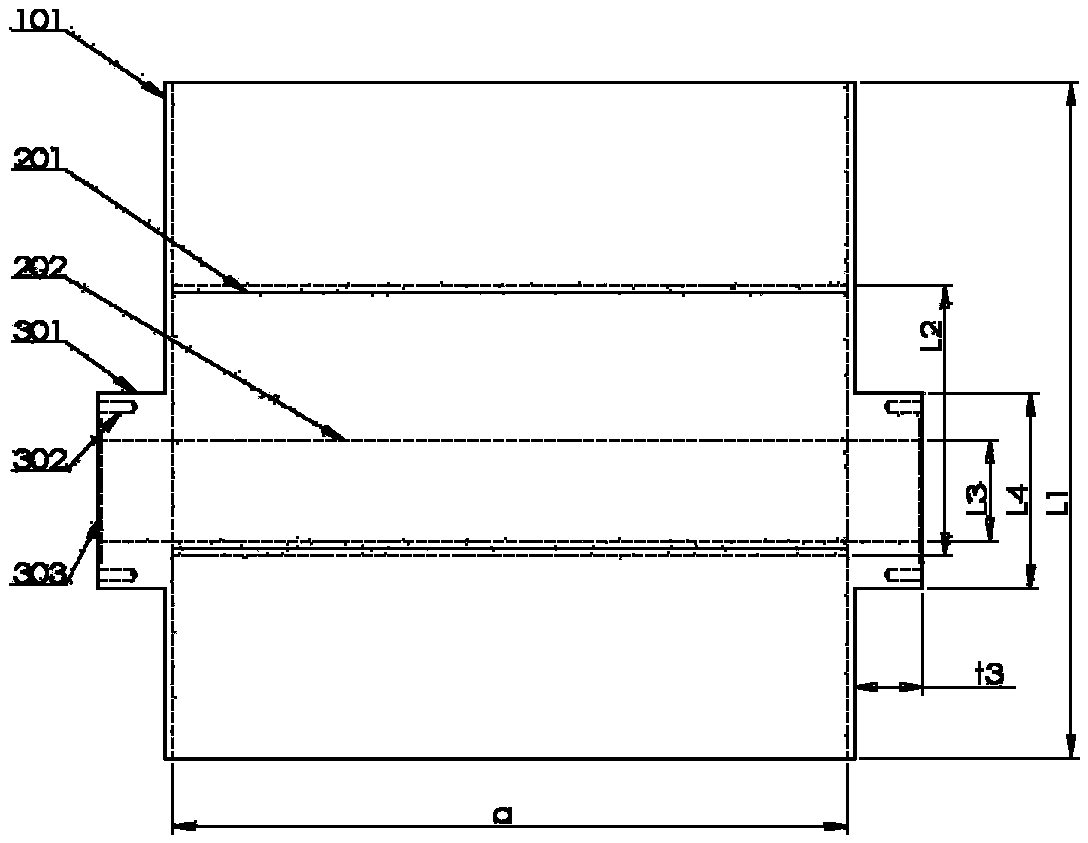

[0034] Transmission Rectangular WaveguideTM according to the present invention 11The mode microwave high-power strip-shaped electron beam collector is composed of a rectangular waveguide 101, an inner conductor 201 and two flanges 301. There are N water channels 202 inside the inner conductor 201 and the flanges 301. In this embodiment, N=3, There are four fixing screw holes 302 on the four corners of the outer end surface of the flange 301, and a sealing ring groove 303 is provided on the outer end surface; the inner conductor 201 is fixed in the axial middle of the rectangular waveguide 101, and its transverse center line The upper and lower inner walls of the rectangular waveguide 101 and the distances between the front and rear ports are equal, and the rectangular waveguide 101 is divided into an upper small waveguide 102 and a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com