Active Energy Radiation Ray Gel-type Resin Composition, Coloring Spacer And/or Black Matrix For Display Element Using Active Energy Radiation Ray Gel-type Resin Composition

An active energy ray, curable resin technology, applied in electrical components, photosensitive materials for opto-mechanical equipment, nonlinear optics, etc., can solve the problems of poor radiation sensitivity and voltage retention, not completely satisfactory, etc. Achieve the effect of excellent adhesion, excellent developability and high radiation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

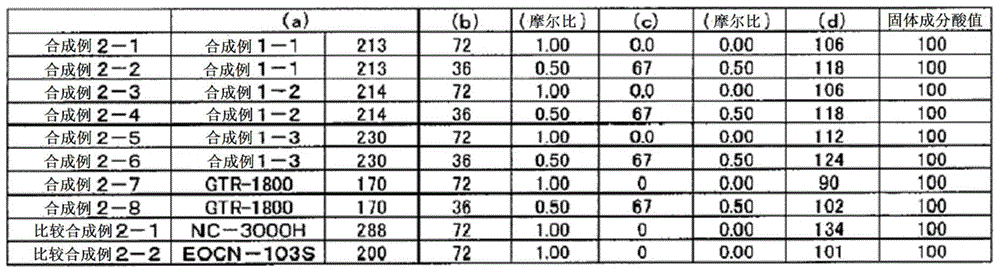

[0172] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these Examples. In addition, in an Example, unless otherwise indicated, a part means a mass part.

[0173] The softening point, epoxy equivalent, acid value, and NMR were measured on the following conditions.

[0174] 1) Epoxy equivalent: measured by a method based on JIS K7236:2001.

[0175] 2) Softening point: Measured by a method based on JIS K7234:1986.

[0176] 3) Acid value: Measured by a method based on JIS K0070:1992.

[0177] 4) 13C-NMR:

[0178] Measuring device: VARIAN NMR system 400MHz

[0179] Solvent: deuterated chloroform

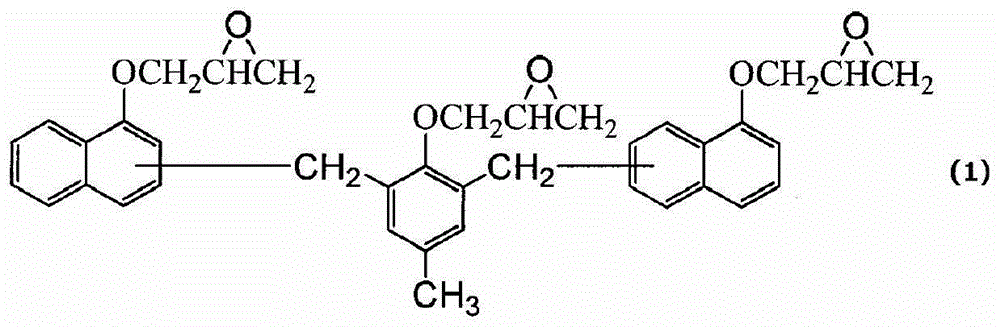

Synthetic example 1-1

[0181] Put 168 parts by mass (1.0 moles) of 2,6-bis(hydroxymethyl)-p-cresol and 1008 parts by mass (7.0 moles) of α-naphthol in a glass container with a thermometer, a reflux cooler, and a stirrer, and add formaldehyde Using 1,500 mL of isobutyl ketone as a solvent, the mixture was stirred at room temperature under a nitrogen atmosphere. 1.7 parts by mass of p-toluenesulfonic acid (1.0 mass % relative to 2,6-bis(hydroxymethyl)-p-cresol) was slowly added while paying attention to heat generation so that the liquid temperature would not exceed 50°C. After the addition, it was heated to 50° C. on an oil bath, and after reacting for 2 hours, 500 mL of methyl isobutyl ketone was added, transferred to a separatory funnel, and washed with water. After washing with water until the washing water became neutral, the organic layer was concentrated under reduced pressure to obtain 370 parts by mass of a pale yellow viscous substance. The softening temperature (JIS K2425 ring and ball met...

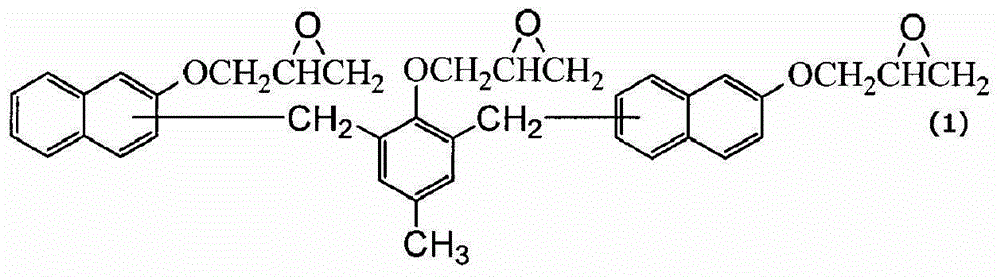

Synthetic example 1-2

[0186] Put 168 parts by mass (1.0 moles) of 2,6-bis(hydroxymethyl)-p-cresol and 1008 parts by mass (7.0 moles) of β-naphthol in a glass container with a thermometer, a reflux cooler, and a stirrer, and add formaldehyde Using 1,500 mL of isobutyl ketone as a solvent, the mixture was stirred at room temperature under a nitrogen atmosphere. 1.7 parts by mass of p-toluenesulfonic acid (1.0 mass % relative to 2,6-bis(hydroxymethyl)-p-cresol) was slowly added while paying attention to heat generation so that the liquid temperature would not exceed 50°C. After the addition, it was heated to 80° C. on an oil bath, and after reacting for 2 hours, 500 mL of methyl isobutyl ketone was added, transferred to a separatory funnel, and washed with water. After washing with water until the washing water became neutral, the organic layer was concentrated under reduced pressure to obtain 371 parts by mass of a yellow solid. The softening temperature (JIS K2425 ring and ball method) was 113° C.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com