A reciprocating linear motion and circular motion conversion device

A technology of reciprocating linear motion and circular motion, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as increasing uneven friction and impact, accelerating cylinder wall wear, and reducing engine output power. Achieve the effects of reducing uneven friction and impact, improving work efficiency, and reducing lateral wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

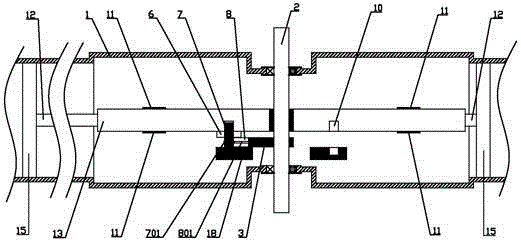

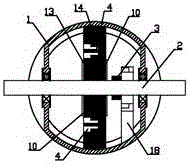

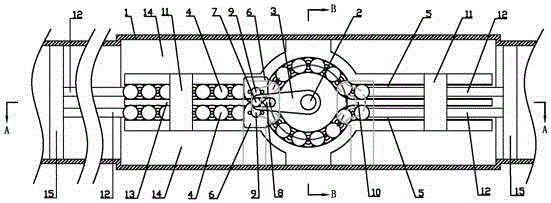

[0051] Such as Figure 1 to Figure 17 In the schematic diagram of the first embodiment of the reciprocating linear motion and circular motion conversion device of the present invention shown, two transmission chain grooves 5 are symmetrically arranged on the upper and lower sides of the transmission shaft 2, and the groove outer sides 14 of the two transmission chain grooves 5 are connected to The shell 1 is fixedly connected, the inner side 13 of the groove is fixedly connected with the outer side 14 of the groove through the connecting plate 11; the two transmission chains 4 are respectively placed in the two transmission chain grooves 5, and the width of the transmission chain 4 is designed to be equal to the width of the transmission chain groove 5 The two ends of each transmission chain 4 are respectively fixedly connected with a connecting rod 12; the transmission shaft 2 is installed in the bearing seat on the housing 1 through the round hole provided at the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com