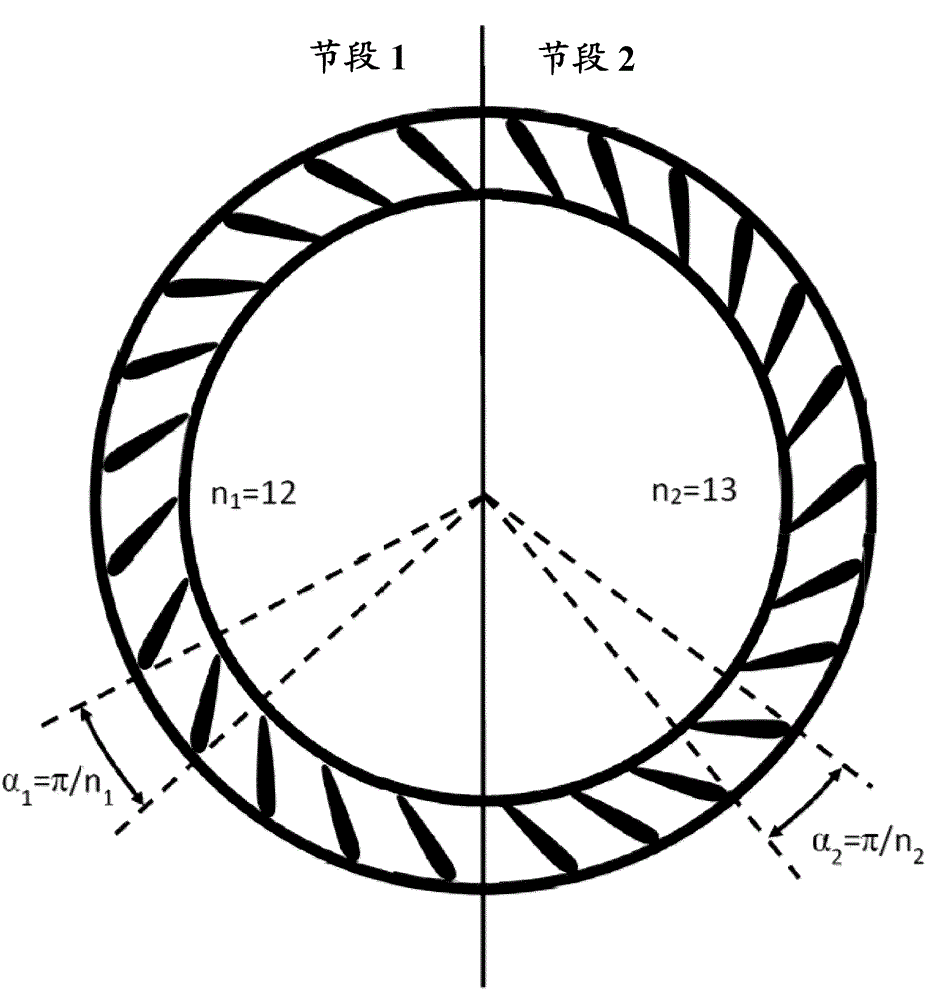

Nozzle Ring With Non-uniformly Distributed Airfoils And Uniform Throat Area

A nozzle ring and root technology, which is applied to the components of the pumping device for elastic fluids, engine functions, liquid fuel engines, etc., can solve the problems of reduced thermal efficiency of the turbine stage, uneven flow, etc. Reduced production and maintenance costs, high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

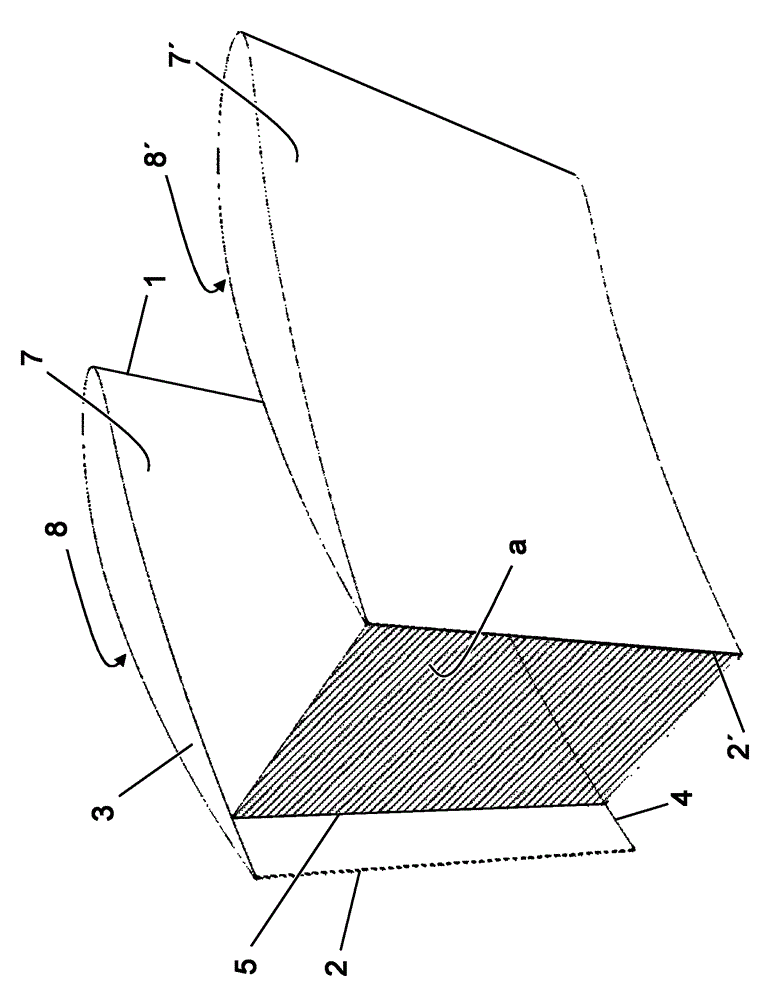

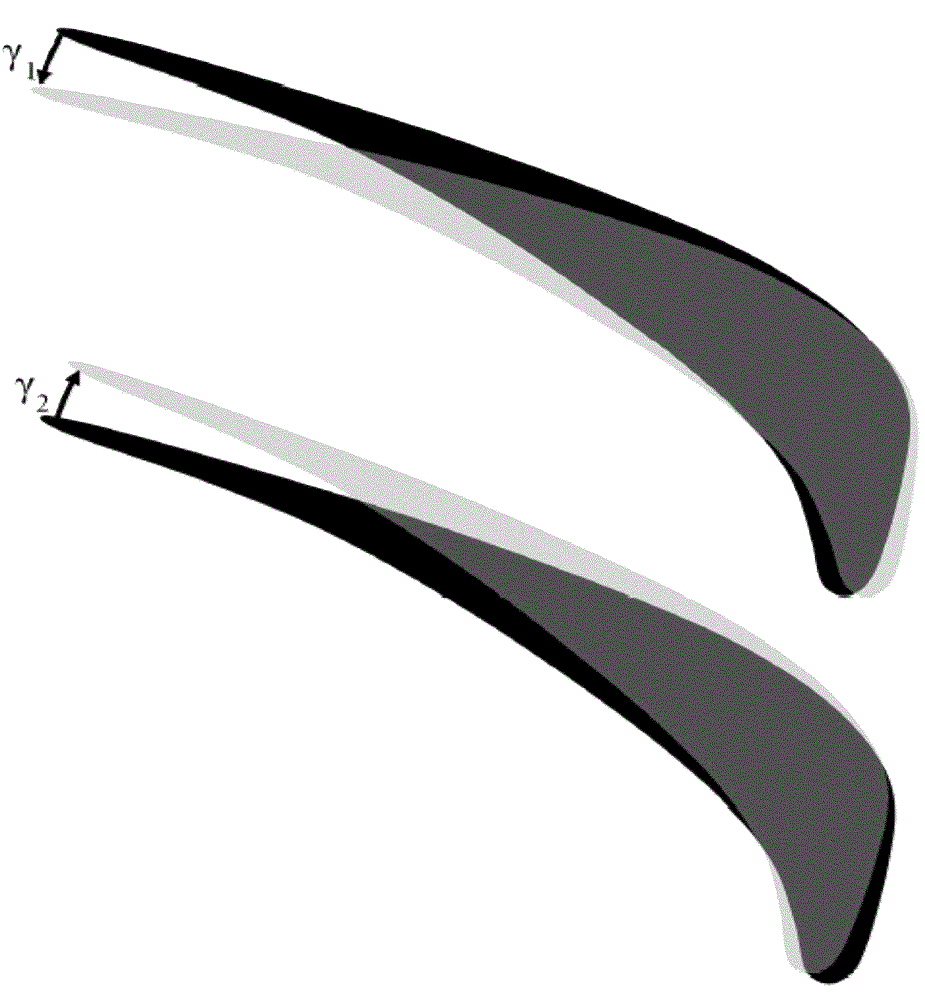

[0030] Each vane of the nozzle ring comprises a root portion conventionally fixedly attached to the inner support ring, a tip portion conventionally fixedly attached to the outer support ring, a leading edge facing the upstream direction, a trailing edge facing the downstream direction , and oppositely oriented suction (or convex) and pressure (or concave) sides that extend from the leading edge to the trailing edge, and between the root and the tip.

[0031] Adjacent vanes define converging passages between them to direct combustion gases between the vanes, through a throat, and downstream from the throat to a conventional turbine rotor stage (not shown). ).

[0032] as stated above and Figure 4 Each vane has a leading edge 1 and a trailing edge 2 as shown in . Each vane has a root 4 immovably attached to one support ring, and a tip 3 immovably attached to the other support ring. The pressure side 7 , 7 ′ and the suction side 8 , 8 ′ extend from the leading edge 1 to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com