Production method for nylon lace

A technology for lace and production method, which is applied in the manufacture of rayon, single-component polyamide rayon, braid and other directions, can solve the problems of complicated process, no hardening, single raw material, etc., and achieves a simple and comfortable production process. The effect of wearability, fluid drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

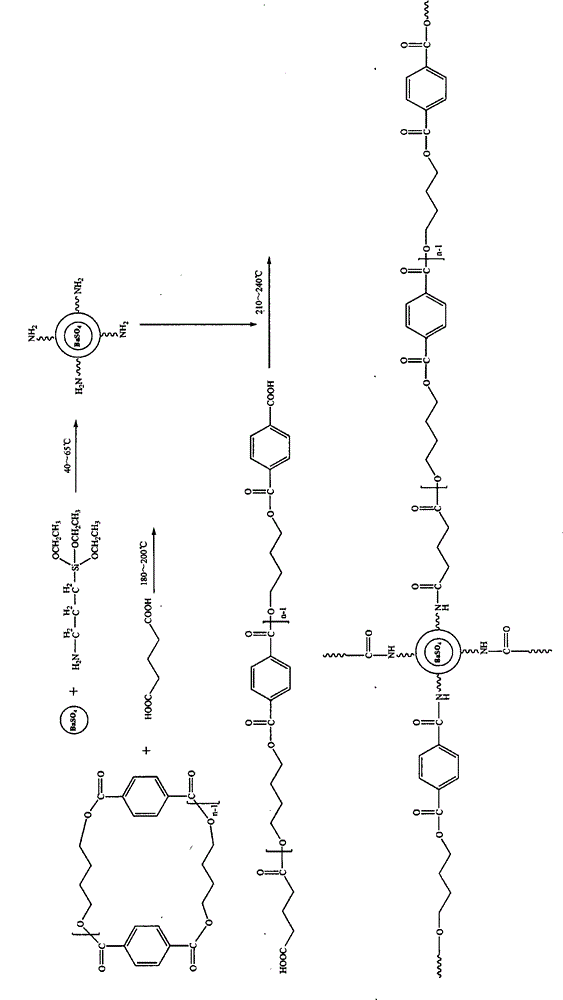

Method used

Image

Examples

Embodiment 1

[0045] A kind of production method of lace lace, lace lace comprises base layer and decorative layer, is provided with decorative layer on base layer, and is fixed by weaving between two layers; Described decorative layer is polynylon composite yarn, modal fiber and modified nylon yarn , the mass ratio of the three raw materials is 9:1:10; the modified nylon yarn is nylon yarn containing nano barium sulfate.

[0046] The base material is lace and non-elastic fabric.

[0047] The decorative layer accounts for 40% of the area of the base layer.

[0048] The production method of described modified nylon yarn, its specific technological process is:

[0049] (1) Surface treatment of nano barium sulfate

[0050] Dissolve nano barium sulfate in ethanol solvent, the concentration of nano barium sulfate in ethanol is 30kg / m 3 , the pH of the ethanol solvent is controlled to be 8, and then aminopropyltriethoxysilane is added for reaction; after the reaction is completed, centrifuga...

Embodiment 2

[0070] A kind of production method of lace lace, lace lace comprises base layer and decorative layer, is provided with decorative layer on base layer, and is fixed by weaving between two layers; Described decorative layer is polynylon composite yarn, modal fiber and modified nylon yarn , the mass ratio of the three raw materials is 9:1:10; the modified nylon yarn is nylon yarn containing nano barium sulfate.

[0071] The base material is lace and non-elastic fabric.

[0072] The decorative layer accounts for 60% of the area of the base layer.

[0073] The production method of described modified nylon yarn, its specific technological process is:

[0074] (1) Surface treatment of nano barium sulfate

[0075] Dissolve nano barium sulfate in ethanol solvent, the concentration of nano barium sulfate in ethanol is 40kg / m 3 , the ethanol solvent pH control is 8.5, then adds aminopropyltriethoxysilane and reacts; After the reaction is completed, centrifugation is carried out, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com