Method for producing chymosin from paenibacillus damxungensissp.nov. in bran culture medium

A technology of bran culture medium and Paenibacillus, applied in the biological field, can solve the problems of low yield and low yield, and achieve the effects of saving social resources, improving vitality, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 seed liquid

[0026] Take 30mL TYC liquid culture medium and place them in 100mL Erlenmeyer flasks, seal with multi-layer (8-12 layers) gauze, seal with kraft paper, and sterilize with high-temperature steam at 121°C for 15 minutes;

[0027] Pick the fresh culture of Paenibacillus damxungensis sp.nov. CGMCC No.8333 cultured on TYC solid medium (agar) for 24 hours, inoculate it into TYC liquid medium, and culture it on a shaker at 30°C for 20 hours to obtain seeds liquid.

Embodiment 2

[0029] The seed liquid that embodiment 1 prepares is inoculated by liquid medium 5% (percentage by volume), in 20mL bran culture medium (the bran content of described bran culture medium is 3%, all the other are deionized water) For fermentation, set the temperature of the shaker at 30° C. and the rotation speed of 300 r / min, and shake the fermentation for 20 hours.

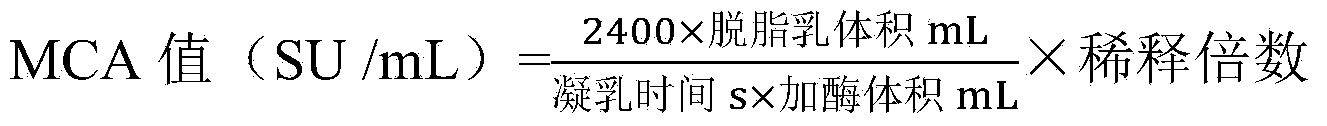

[0030] After culturing for 20 hours, take 5 mL of fermentation broth, centrifuge at 4°C and 9000 r / min, and the supernatant obtained is the crude enzyme solution. The obtained crude enzyme solution was diluted 5 times, and 0.5 mL of the diluted solution was taken to determine the MCA value.

[0031] The experimental results showed that the chymosin activity of 20mL bran cultured crude enzyme liquid of Paenibacillus damxungensis sp.nov. CGMCC No.8333 was shaken and fermented at 30°C for 20 hours, and the activity of rennet was 4760.71SU / mL.

Embodiment 3

[0033] The seed liquid that embodiment 1 prepares is inoculated by liquid medium 5% (percentage by volume), in 40mL bran culture medium (the bran content of described bran culture medium is 3%, all the other are deionized water) For fermentation, set the temperature of the shaker at 30° C. and the rotation speed of 300 r / min, and shake the fermentation for 20 hours.

[0034]After culturing for 20 hours, take 5 mL of fermentation broth, centrifuge at 4°C and 9000 r / min, and the supernatant obtained is the crude enzyme solution. The obtained crude enzyme solution was diluted 5 times, and 0.5 mL of the diluted solution was taken to determine the MCA value.

[0035] The experimental results showed that the rennet activity of 40mL bran cultured crude enzyme solution of Paenibacillus damxungensis sp.nov. CGMCC No.8333 was shaken and fermented at 30°C for 20 hours, and the rennet activity was 4578.64SU / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com