Dental implant and 3D printing preparation method thereof

A technology for dental implants and manufacturing methods, which is applied in dental prostheses, dental implants, dentistry, etc., can solve the problems of poor dental implant effect, low processing efficiency, and non-integration, and achieves controllable roughness and processing. Efficiency and cost reduction, reduced bone loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

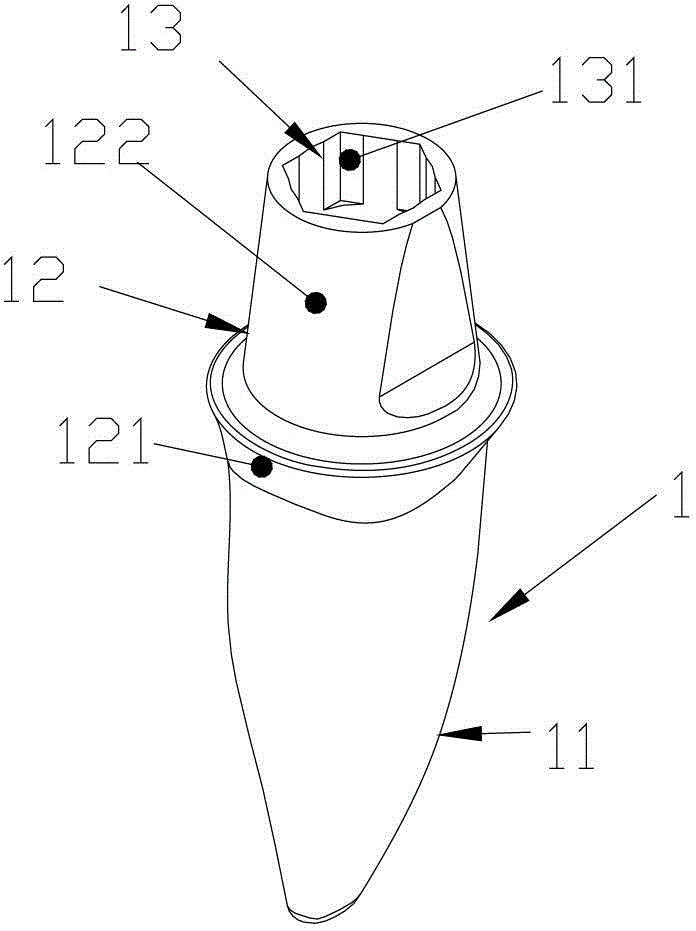

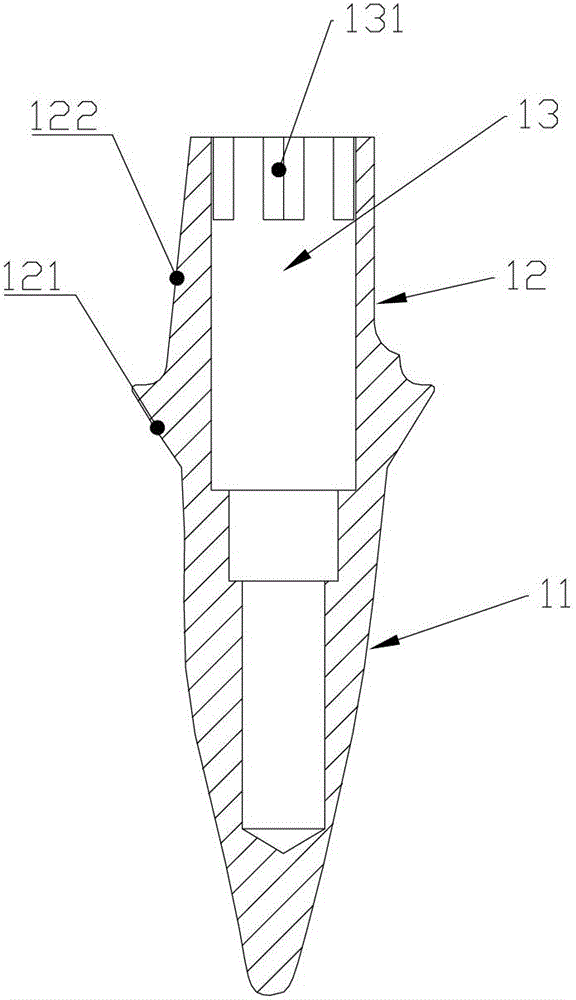

[0032] Such as figure 1 and figure 2 Shown is the dental implant 1 according to the present invention, which includes a dental implant body 11 and an abutment portion 12 .

[0033] The abutment portion 12 is disposed on the upper side of the dental implant body 11 , and the abutment portion 12 is integrally formed with the dental implant body 11 . The dental implant body 11 includes the tooth root, and the abutment portion 12 includes the gingival part 121 and the main body bonding part 122; The bonding portion 122 is connected by a circular curved surface. The shape of the tooth root is a shape based on the real scanning shape of the human tooth root; the gingival part 121 is an inverted cone or its outer surface is a curved surface; the main body bonding part 122 is a conical truncated part, and one side of the main body bonding part 122 has cut.

[0034] An obturator hole 13 is vertically opened on the upper surface of the dental implant 1 through the abutment portion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com