Slide fastener

一种拉链、拉链带的技术,应用在拉链领域,能够解决间隔拉宽、拉链链牙倾斜或微小运动、啮合强度下降等问题,达到提高摩擦力、抑制姿势变化、维持操作性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

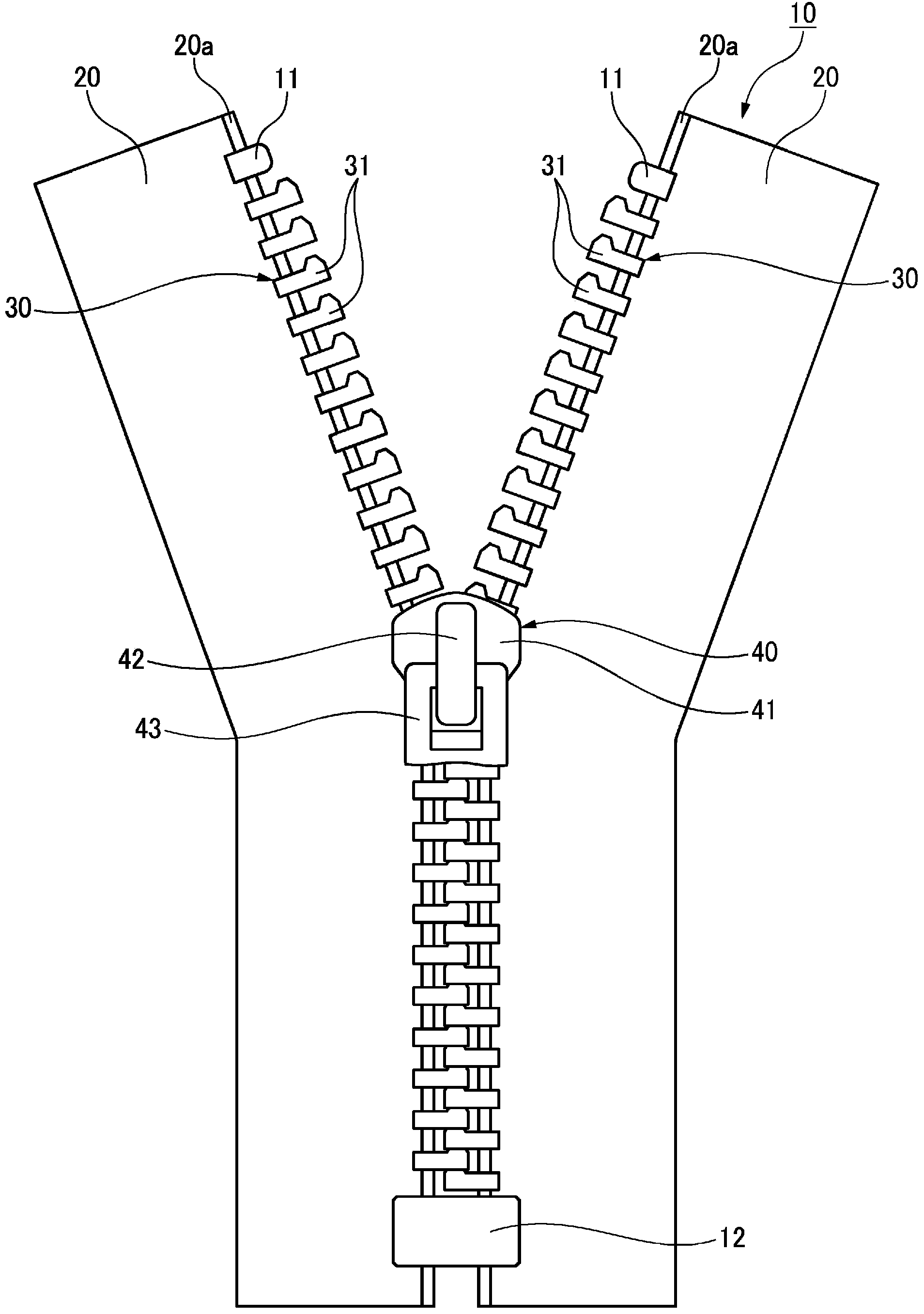

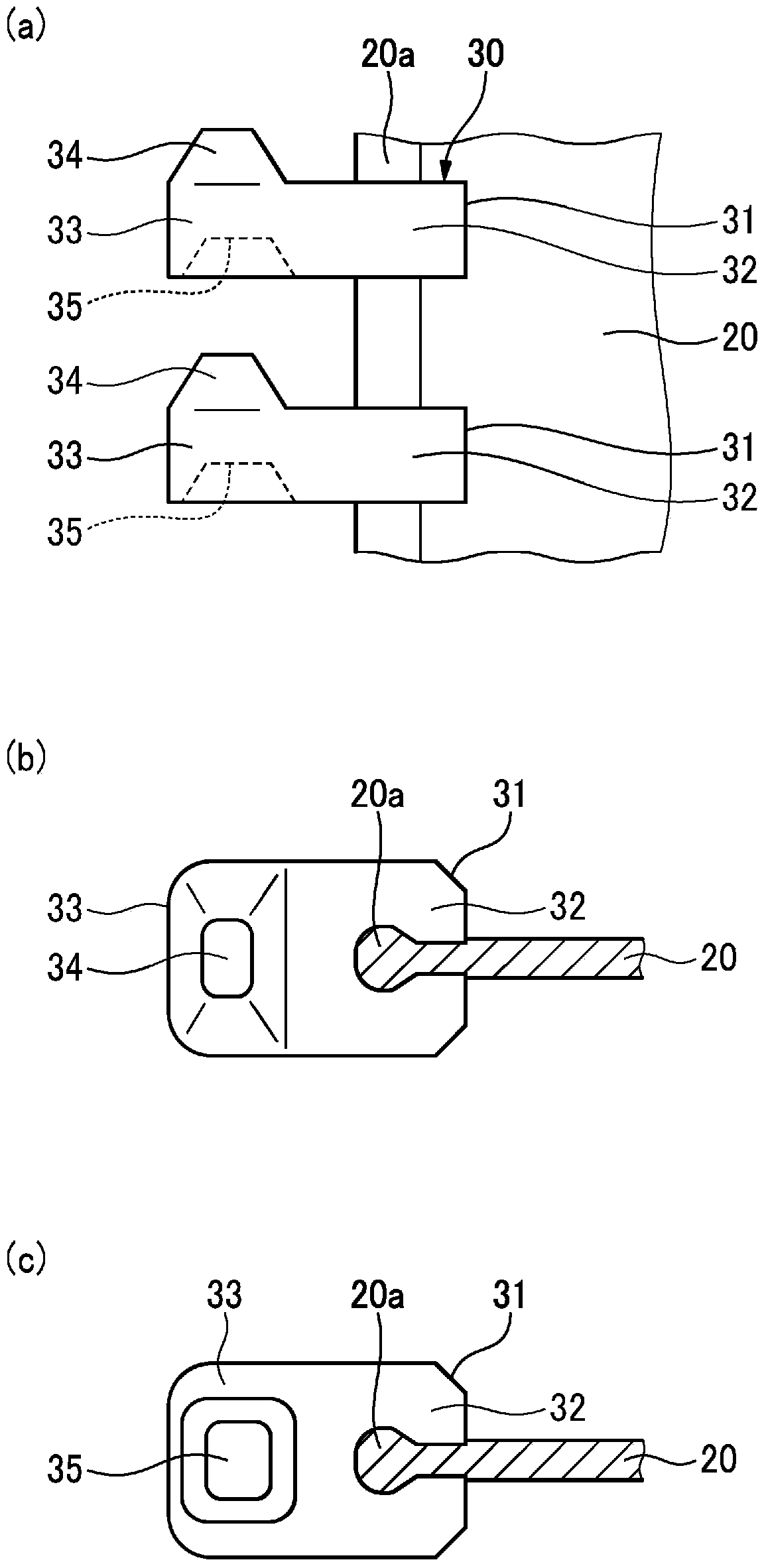

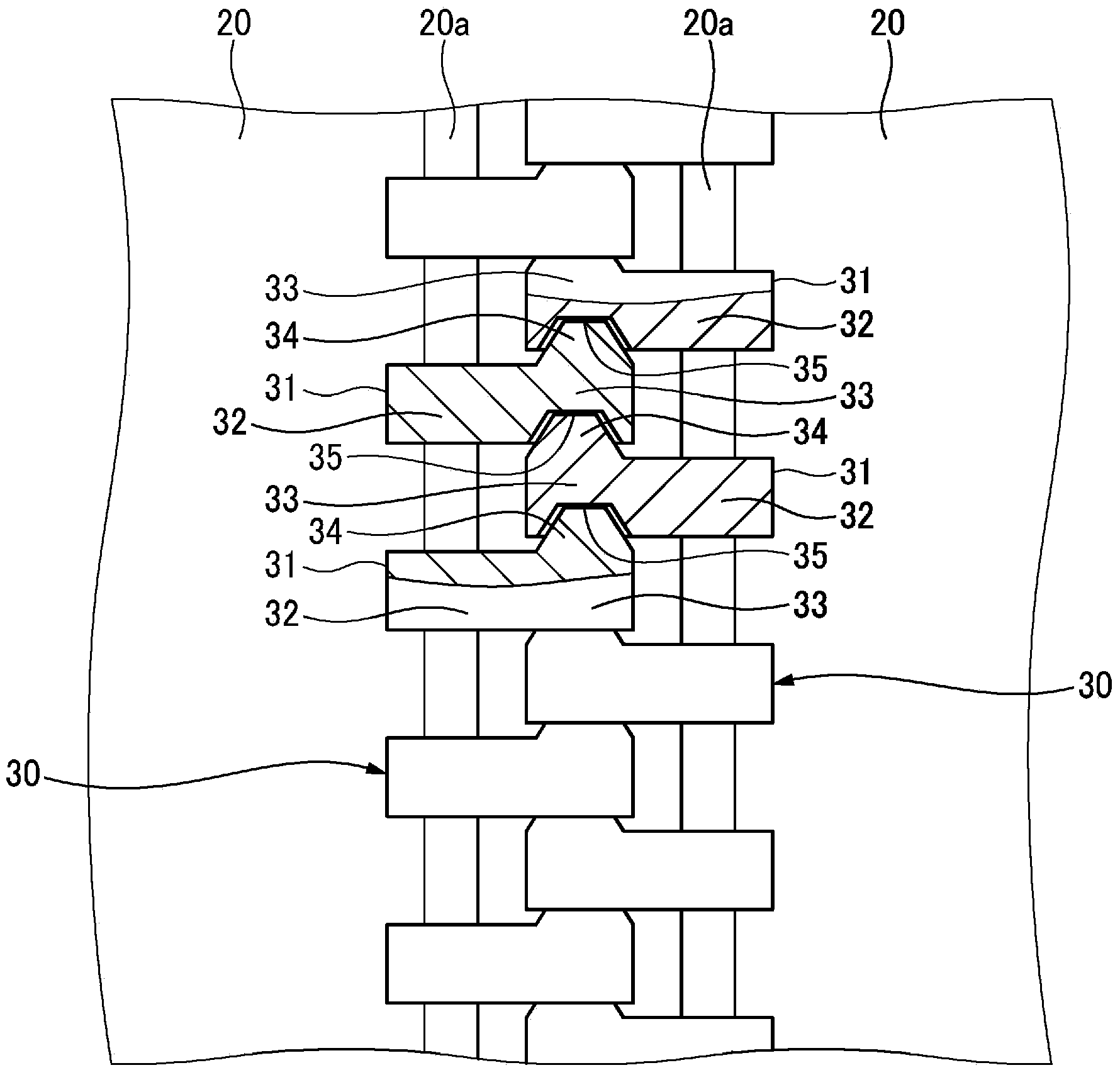

[0036] First, refer to Figure 1 to Figure 7 1st Embodiment of the slide fastener which concerns on this invention is demonstrated.

[0037] Such as figure 1 As shown, the slide fastener 10 of the present embodiment includes: a pair of left and right zipper tapes 20 of textile; a pair of left and right cores 20a, which are respectively arranged along the opposite tape side edges of the left and right pair of zipper tapes 20; a pair of left and right zipper tapes Element rows 30, which are respectively mounted on the left and right pair of core parts 20a, have a plurality of metal zipper elements 31; slider 40, which engages and separates the left and right pair of zipper element rows 30; the upper stop part 11 , which are respectively arranged on the upper end of the left and right pair of zipper element rows 30; In addition, although the application of the slide fastener 10 is mentioned, clothing, a bag, a shoe, industrial goods etc. are mentioned, It is not limited to this...

no. 2 Embodiment approach

[0055] Next, refer to Figure 8 The second embodiment of the slide fastener of the present invention will be described. It should be noted that the same or equivalent parts as those of the above-mentioned first embodiment are assigned the same reference numerals in the drawings, and descriptions thereof are omitted or simplified.

[0056] In this embodiment, silica (silicon oxide) S (refer to Figure 4 ), and on the left and right fastener tapes 20, an anti-seepage agent and a fluorine-based compound are attached. and, if Figure 8 As shown, a predetermined pattern (color) P is formed by inkjet printing (coloring) on the fastener tape 20 , the fastener element 31 , and the fastener tape 20 portion in the vicinity of the fastener element 31 .

[0057] In addition, an opener 13 is provided instead of the lower stopper portion 12 of the first embodiment described above, and the opener 13 includes a box bar 14 and a box body 15 provided at the lower end of the zipper element ...

Embodiment

[0066] Next, in order to confirm the effects of the present invention, a top strength test was performed on the slide fasteners of the present invention and the slide fasteners of the comparative example.

[0067] In this test, slide fasteners 1 to 5 (No. 1 to No. 5) described below were prepared. In addition, as a general specification of the slide fasteners 1 to 5, a fastener tape woven from a polyester thread material is used, and fastener elements are made of red copper. also, Figure 9 The manufacturing process of slide fasteners 1-5 is shown in .

[0068] The slide fastener 1 is a slide fastener in which fastener elements are attached to the core of the fastener tape, and corresponds to a normal slide fastener.

[0069] The slide fastener 2 attaches fastener elements to the core part of a fastener tape, after making an anti-seepage agent adhere to a fastener tape.

[0070] The slide fastener 3 attaches the fastener element to the core part of the fastener tape after a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com