Light guide plate and light source module

A light source module, light guide plate technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of bright and dark lines and uneven appearance of the light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

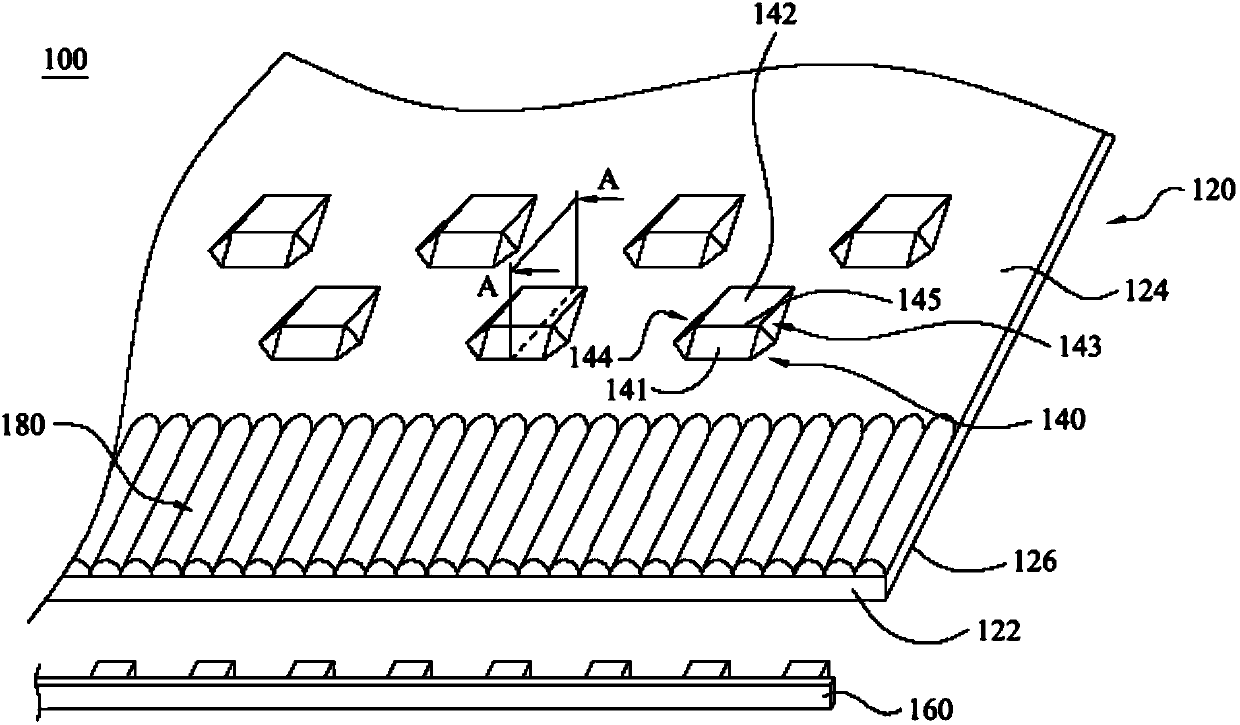

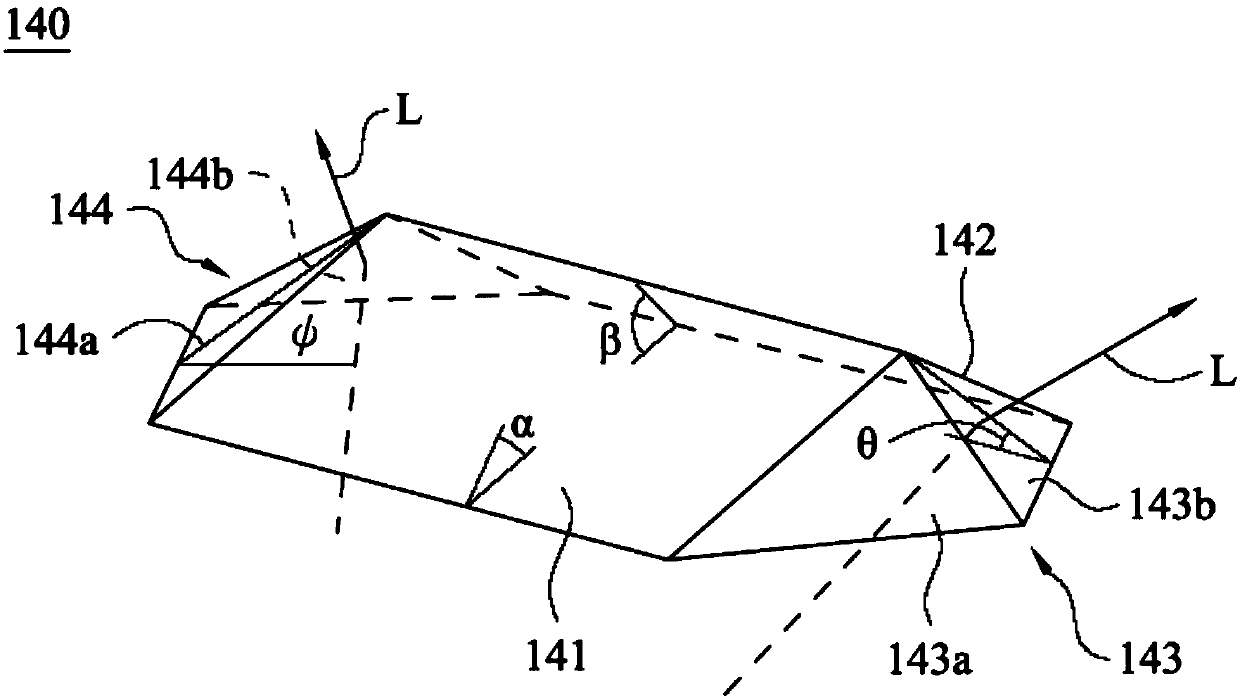

[0048] Please refer to figure 1 , which is a schematic structural view showing a light guide plate according to the first embodiment of the present invention. The light guide plate 100 of this embodiment can be applied to a backlight module or a lamp. The light guide plate 100 may include a main body 120 and a plurality of microstructures 140 . The microstructure 140 is disposed on the body 120 . Through the arrangement of the microstructure 140 , the optical trend of the light guide plate 100 can be adjusted, and the uniformity of the light appearance of the light guide plate 100 can be improved.

[0049] In the light guide plate 100, the main body 120 can be a light-transmitting plate or other equivalent light-transmitting components. The main body 120 mainly includes a light incident surface 122 and a light output surface 124 . The light emitting surface 124 is connected to the light incident surface 122 . The light source 160 can be disposed beside the light incident ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com