Multiple Sample Attachment to Nano Manipulator for High Throughput Sample Preparation

A nanomanipulator and manipulator technology, applied in sampling, instruments, scientific instruments, etc., can solve laborious and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A preferred embodiment of the present invention provides a method of picking up multiple samples and placing them on a TEM sample holder or TEM grid, which is done to increase throughput in a process that would involve less labor.

[0036] The preferred method or apparatus of the invention has many novel aspects, and since the invention can be embodied in different methods or apparatus for different purposes, it is not necessary to describe every aspect in every embodiment. Furthermore, many aspects of the described embodiments are individually patentable.

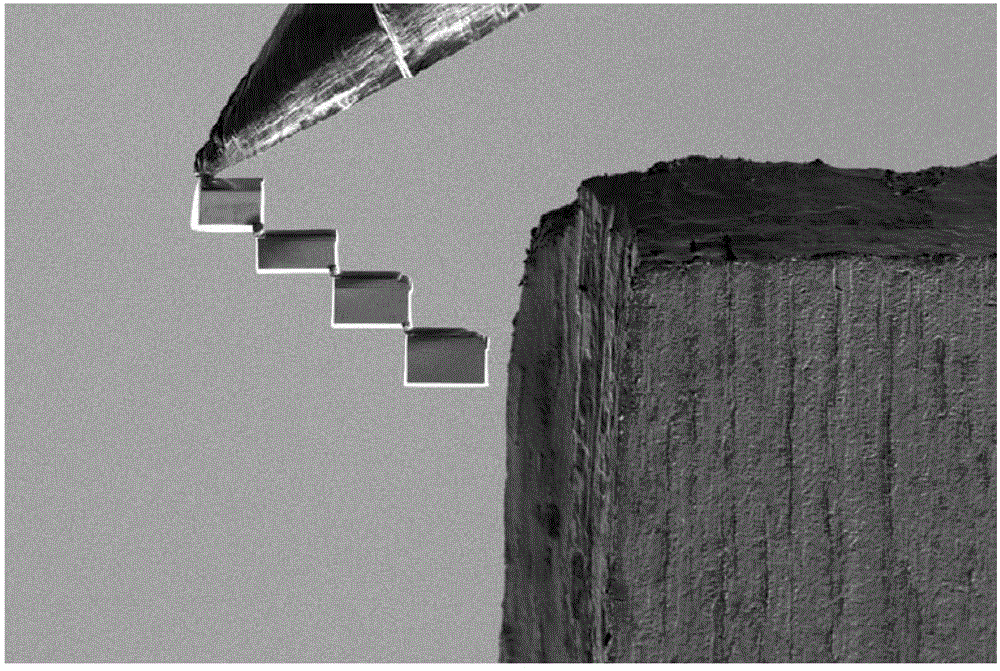

[0037] In a preferred embodiment of the invention, one or more thin layers are first created on a wafer or other substrate. image 3 Shown are a plurality of thin layers 100 that have been ground or machined in preparation for removal from the wafer. Preferably, automated ex-situ processes can be used to create multiple thin layers, as described in "Method for S / TEM Sample Analysis" by Blackwood et al., U.S. Provis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com