A kind of preparation method of co-p nano catalytic material

A nano-catalytic material, co-p technology, applied in the field of preparation of Co-P nano-catalytic materials, can solve the problem of single Co-P particle morphology, achieve good recycling performance, wide application prospects, and speed up the reaction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

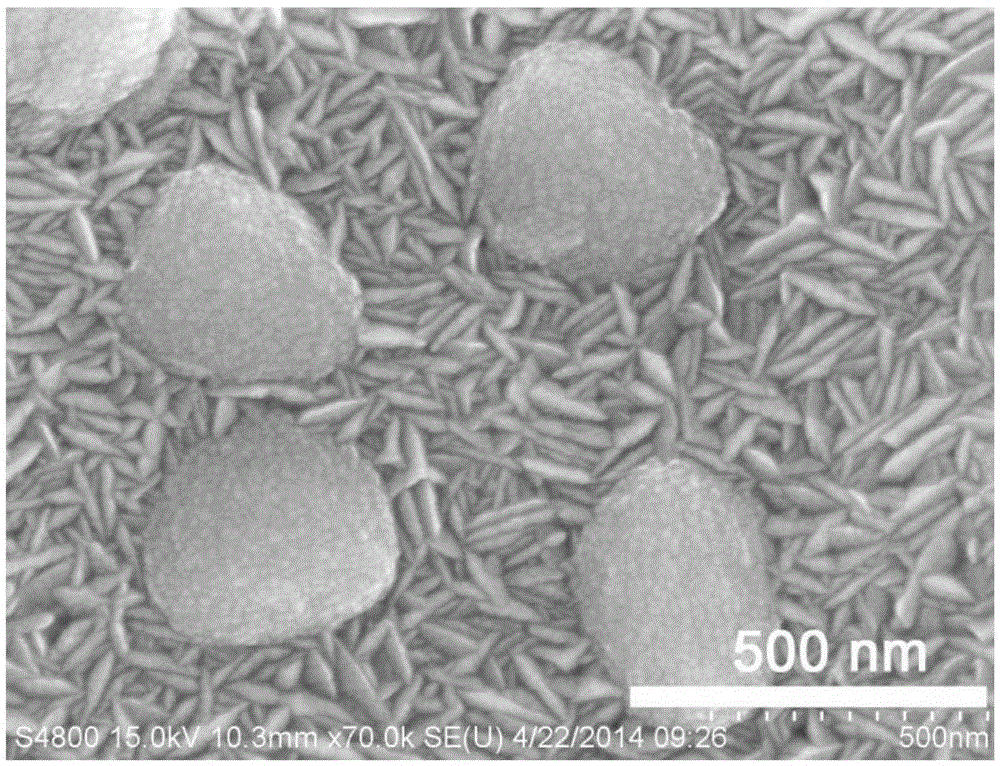

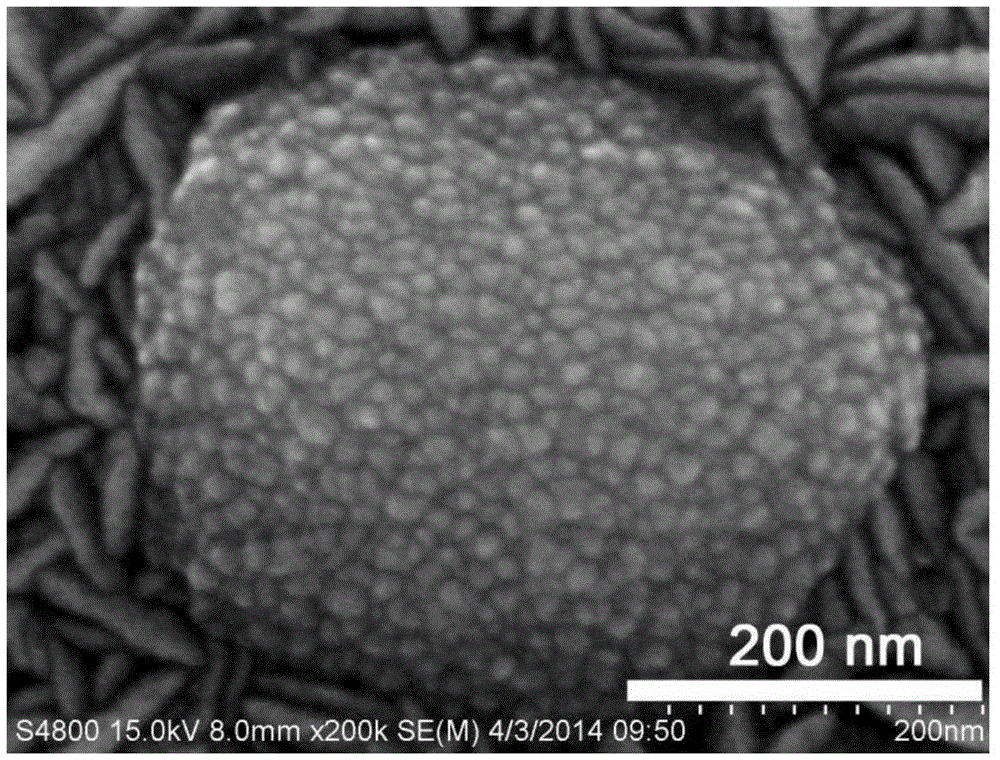

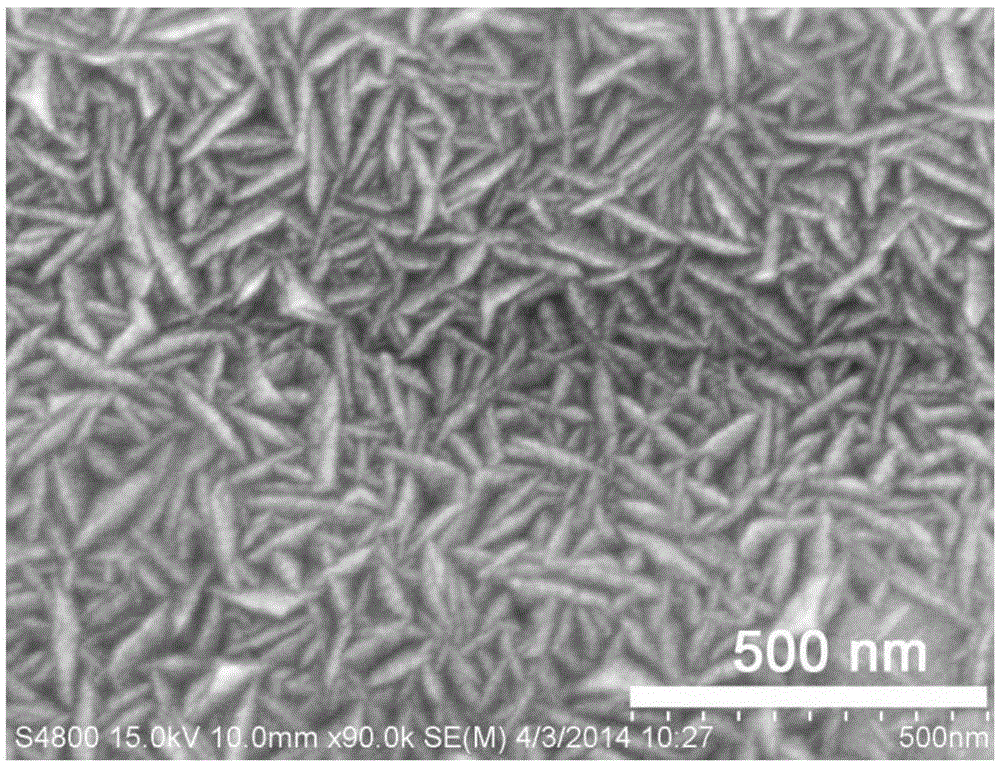

Image

Examples

Embodiment 1

[0026] A kind of preparation method of Co-P nano catalytic material is realized by following specific steps:

[0027] (1) Prepare copper etching solution: measure 50mL phosphoric acid, 35mL acetic acid, 15mL nitric acid and mix to make 100mL copper etching solution;

[0028] (2) Preparation of sensitizing solution: Weigh 1 g of stannous chloride dihydrate and ultrasonically dissolve it in 5 mL of hydrochloric acid, add distilled water to make the volume to 1 L, and make a sensitizing solution;

[0029] (3) Preparation of activation solution: Weigh 0.1 g of palladium chloride and ultrasonically dissolve it in 1 mL of hydrochloric acid, add distilled water to make the volume to 1 L, and prepare the activation solution;

[0030] (4) Preparation of chemical plating solution: 1. dissolving 2.379g cobalt chloride hexahydrate in 100mL distilled water to form a cobalt salt solution with a concentration of 0.1mol / L; 2. adding 4.5g glycine to the above-mentioned cobalt salt solution to ...

Embodiment 2

[0033] A kind of preparation method of Co-P nano catalytic material is realized by following specific steps:

[0034] (1) prepare copper corrosion solution, sensitization solution and activation solution respectively with step (1), step (2), step (3) in embodiment 1;

[0035] (2) Preparation of chemical plating solution: 1. dissolving 2.812g cobalt sulfate heptahydrate in 100mL distilled water to form a cobalt salt solution with a concentration of 0.1mol / L; 2. adding 4.503g glycine to the above cobalt salt solution to make the cobalt salt Mix evenly with glycine to form Co 2+ : Glycine molar ratio is the clarification solution of 1:6; 3. be that the surfactant polyvinyl alcohol (PVA-124) of 0.1% is joined in above-mentioned clarification solution with weight percent concentration; 4. add 6.359g reductive agent secondary Sodium phosphate in the above mixed solution; ⑤Put the mixed solution in step ④ into a constant temperature water bath at 70°C for 5 minutes, and adjust the p...

Embodiment 3

[0038] A kind of preparation method of Co-P nano catalytic material is realized by following specific steps:

[0039] (1) prepare copper corrosion solution, sensitization solution and activation solution respectively with step (1), step (2), step (3) in embodiment 1;

[0040] (2) Preparation of chemical plating solution: 1. dissolving 2.812g cobalt sulfate heptahydrate in 100mL distilled water to form a cobalt salt solution with a concentration of 0.1mol / L; 2. adding 4.503g glycine to the above cobalt salt solution to make the cobalt salt Mix evenly with glycine to form Co 2+ : Glycine molar ratio is the clarification solution of 1:6; 3. be that the surfactant polyvinyl alcohol (PVA-124) of 0.1% is joined in above-mentioned clarification solution with weight percent concentration; 4. add 6.359g reductive agent secondary Sodium phosphate in the above mixed solution; ⑤Put the mixed solution in step ④ into a constant temperature water bath at 70°C for 5 minutes, and adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com