Method for extracting and preparing polysaccharide from inonotus obliquus

A technology of Inonotus obliquus and polysaccharides, applied in the biological field, to achieve the effect of improving the removal rate, no toxic side effects, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

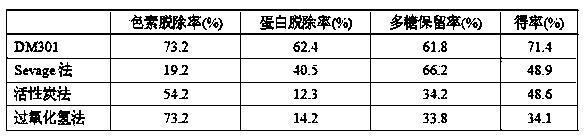

Method used

Image

Examples

Embodiment 1

[0019] Example 1 The method for extracting and preparing the polysaccharide of Inonotus obliquus from Inonotus obliquus comprises the following steps:

[0020] A. Degreasing pretreatment of raw materials: take the dried Inonotus obliquus sclerotia, crush them, soak them in 4 times the volume of 60% ethanol solution for 16 hours to remove fat, some mono (oligo) sugars and fat-soluble pigments, and keep the residue in a cool place Let dry.

[0021] B. Preparation of crude polysaccharide by hot water extraction: After the pretreated residue is air-dried, add 10 times distilled water (v / w), extract in boiling water for 1 h, filter with 80-mesh gauze, concentrate the filtrate, centrifuge, and spray-dry to obtain crude polysaccharide.

[0022] C. Crude polysaccharide enzymatic hydrolysis: dissolve the crude polysaccharide in water to prepare a 0.5% (w / w) aqueous solution, add papain, the amount of papain added is 3% (w / w) of the crude polysaccharide aqueous solution, react at 3...

Embodiment 2

[0026] Example 2 The method for extracting and preparing the polysaccharide of Inonotus obliquus from Inonotus obliquus comprises the following steps:

[0027] A. Degreasing pretreatment of raw materials: Take the dried Inonotus obliquus sclerotia, crush them, soak them in 8 times the volume of 95% ethanol solution for 24 hours to remove fat, some mono (oligo) sugars and fat-soluble pigments, and keep the residue in a cool place Let dry.

[0028] B. Preparation of crude polysaccharide by hot water extraction: After the pretreated residue is air-dried, add 20 times distilled water (v / w), extract with boiling water for 3 hours, filter with 120-mesh gauze, repeat the extraction of the filter residue twice, combine the filtrate, concentrate, centrifuge, and spray Dried crude polysaccharides.

[0029] C. Crude polysaccharide enzymatic hydrolysis: dissolve the crude polysaccharide in water to prepare a 2.0% (w / w) aqueous solution, add papain, the amount of papain added is 5% (...

Embodiment 3

[0034] Example 3 The method for extracting and preparing the polysaccharide of Inonotus obliquus from Inonotus obliquus, it comprises the steps:

[0035] A. Degreasing pretreatment of raw materials: take the dried Inonotus obliquus sclerotia, crush them, soak them in 7 times the volume of 90% ethanol solution for 20 hours to remove fat, some mono (oligo) sugars and fat-soluble pigments, and keep the residue in a cool place Let dry.

[0036] B. Preparation of crude polysaccharide by hot water leaching: After the pretreated residue is air-dried, add 18 times distilled water (v / w), extract with boiling water for 2.5 hours, filter with 100-mesh gauze, repeat the extraction of the filter residue 3 times, combine the filtrate, concentrate, centrifuge, and spray Dried crude polysaccharides.

[0037] C. Crude polysaccharide enzymatic hydrolysis: dissolve the crude polysaccharide in water to prepare a 1.8% (w / w) aqueous solution, add papain, the amount of papain added is 4.5% (w / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com