A kind of wear-resistant antiskid concrete and its construction method

A construction method and concrete technology, which is applied in the field of building materials, can solve the problems of concrete being non-wear-resistant and easy to slip, and achieve good anti-skid performance and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

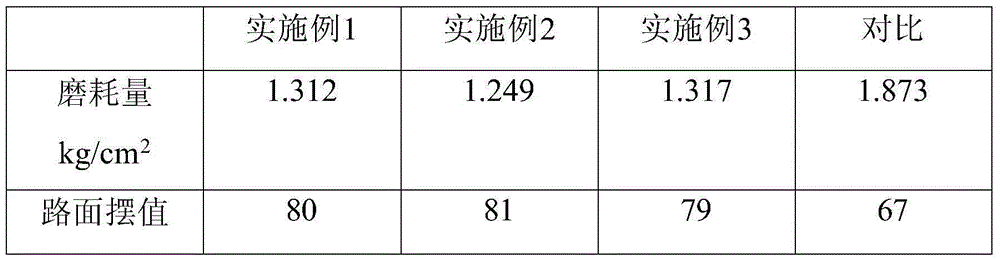

Examples

Embodiment 1

[0014] A wear-resistant and anti-slip concrete, comprising the following raw materials in parts by weight: 100 parts of Portland cement, 40 parts of sand, 10 parts of glyoxal, 50 parts of dimethylol urea, 40 parts of aluminum trichloride, and 70 parts of sodium fatty acid 80 parts of ammonium chloride, 10 parts of limestone, 30 parts of fly ash, 45 parts of desulfurization ash, 75 parts of steel slag, 10 parts of potassium nitrate, 15 parts of glass powder, 55 parts of accelerator dimethylaniline, and 80 parts of water.

[0015] The diameter of the glass powder is 20 microns.

[0016] The construction method of wear-resistant and non-slip concrete comprises the following steps: uniformly mix Portland cement, sand, glyoxal, dimethylol urea, aluminum trichloride, sodium fatty acid, potassium nitrate, glass powder, and water, and heat to 180℃, stir for 25s, add accelerator, stir evenly, then add ammonium chloride, limestone, fly ash, desulfurization ash, steel slag, stir evenly, ...

Embodiment 2

[0018] A wear-resistant and anti-slip concrete, comprising the following raw materials in parts by weight: 120 parts of Portland cement, 90 parts of sand, 30 parts of glyoxal, 60 parts of dimethylol urea, 65 parts of aluminum trichloride, and 80 parts of sodium fatty acid 100 parts of ammonium chloride, 60 parts of limestone, 42 parts of fly ash, 85 parts of desulfurization ash, 95 parts of steel slag, 55 parts of potassium nitrate, 20 parts of glass powder, 100 parts of accelerator cobalt naphthenate, and 120 parts of water.

[0019] The diameter of the glass powder is 40 microns.

[0020] The construction method of wear-resistant and non-slip concrete comprises the following steps: uniformly mix Portland cement, sand, glyoxal, dimethylol urea, aluminum trichloride, sodium fatty acid, potassium nitrate, glass powder, and water, and heat to 180°C, stir for 20s, add accelerator, stir evenly, then add ammonium chloride, limestone, fly ash, desulfurization ash, steel slag, stir e...

Embodiment 3

[0022] A wear-resistant and anti-skid concrete, comprising the following raw materials in parts by weight: 110 parts of Portland cement, 80 parts of sand, 18 parts of glyoxal, 58 parts of dimethylol urea, 60 parts of aluminum trichloride, and 78 parts of sodium fatty acid 90 parts of ammonium chloride, 50 parts of limestone, 40 parts of fly ash, 75 parts of desulfurization ash, 90 parts of steel slag, 45 parts of potassium nitrate, 18 parts of glass powder, 90 parts of accelerator dimethylaniline, and 110 parts of water.

[0023] The diameter of the glass powder is 25 microns.

[0024] The above-mentioned construction method of wear-resistant and non-slip concrete comprises the following steps: uniformly mixing Portland cement, sand, glyoxal, dimethylol urea, aluminum trichloride, sodium fatty acid, potassium nitrate, glass powder, and water, heating To 190°C, stir for 25s, add accelerator, stir evenly, then add ammonium chloride, limestone, fly ash, desulfurization ash, steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com