Graphene three-dimensional hierarchical porous carbon material and preparation method thereof

A hierarchically porous and graphene technology, applied in the field of graphene three-dimensional hierarchical porous carbon material and preparation, can solve the problems of high cost and complex preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

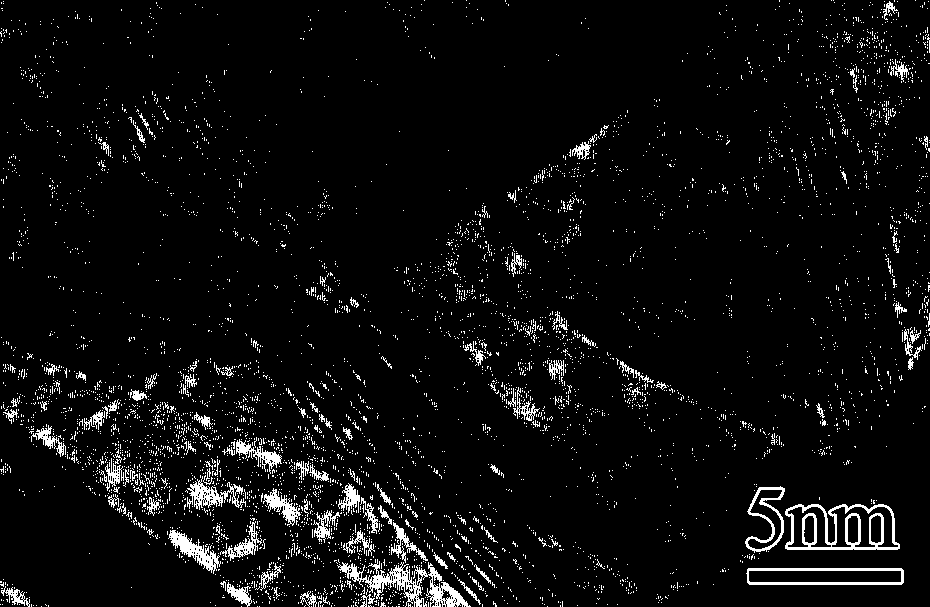

Image

Examples

Embodiment 1

[0023] Add 1000 g of coconut shell powder to 1 L of disodium ethylenediaminetetraacetic acid solution with a mass concentration of 0.25%, mix well, place in a constant temperature water bath, treat at 85°C for 1.5h, wash and filter to separate the filter residue, Add 1 L of 7% H 2 o 2 Solution, 11% acetic acid, 8.5% nitric acid and 5% KCl were ultrasonically treated for 25 minutes, placed in a constant temperature water bath at 70°C, heated for 7 hours, cooled to room temperature, separated by filtration, and repeatedly washed with deionized water. Wash the filter residue until neutral, dry the filter residue, and then carbonize the obtained product at 850°C for 120 minutes under the protection of high-purity inert gas to obtain a carbonized material. Add composite activator (KOH, NaOH, Na 2 CO 3 , K 2 CO 3, ) and 4% deionized water, wherein the mass ratio of activator to carbonized material is 2.5:1, KOH, NaOH, Na 2 CO 3 , K 2 CO 3 The ratio is 1:1:2:2. After being f...

Embodiment 2

[0025] Add 60 g of coconut shell powder to 600 mL of disodium edetate solution with a mass concentration of 0.1%, mix well, place in a constant temperature water bath, treat at 50°C for 3 hours, wash and filter to separate the filter residue, add 600 mL Volume concentration is 4.5% H 2 o 2 Solution, 12% acetic acid, 9% nitric acid and 2.5% KCl were ultrasonically treated for 40 minutes, placed in a constant temperature water bath at 50°C, heated for 8 hours, taken out, cooled to room temperature, separated by filtration, and deionized The filter residue was repeatedly washed with water until neutral, and after drying, the filter residue was carbonized at 600°C for 150 minutes under the protection of high-purity inert gas to obtain carbonized material. Add complex activator (KOH, NaOH, Na 2 CO 3 , K 2 CO 3 ) and 4.5% deionized water, wherein the mass ratio of activator to carbonized material is 3:1, KOH, NaOH, NaOH in composite activator 2 CO 3 , K 2 CO 3 The ratio is ...

Embodiment 3

[0027] Add 40 g of coconut shell powder to 400 mL of disodium edetate solution with a mass concentration of 0.2%, mix well, place in a constant temperature water bath, treat at 90°C for 1 hour, wash and filter to separate the filter residue, add 400 mL 6% H by volume 2 o 2Solution, 15% acetic acid, 8% nitric acid and 4.5% KCl were ultrasonically treated for 20 minutes, placed in a constant temperature water bath at 60°C, heated for 6 hours, taken out, cooled to room temperature, separated by filtration, and deionized The filter residue was repeatedly washed with water until neutral, and after drying, the hemicellulose-removed fruit shell was carbonized at 650°C for 100 minutes under the protection of high-purity inert gas to obtain carbonized material. Add complex activator (KCl, KOH, NaOH, Na 2 CO 3 , K 2 CO 3, ZnCl 2 ) and 5% deionized water, wherein the mass ratio of activator to carbonized material is 4:1, KCl, KOH, NaOH, NaOH in the composite activator 2 CO 3 , K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com