A process for producing direct sponge iron by catalytic partial oxidation of natural gas

A technology for catalytic partial oxidation and natural gas, applied in hydrogen production, chemical industry, chemical recovery, etc., can solve the problems of easy clogged reactors, low cycle life, large temperature gradient of the bed, etc., to achieve simple and efficient process flow, Avoid the danger of explosion and the effect of simple process system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

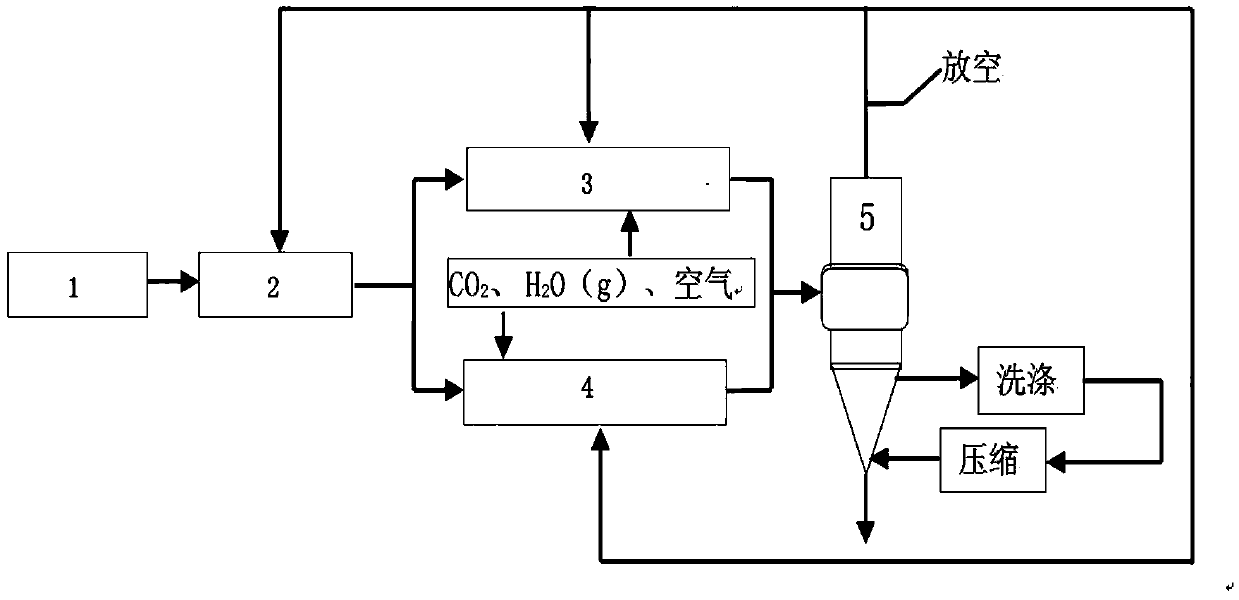

[0022] In order to better illustrate the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The process steps of the invention include:

[0023] (1) After natural gas (about 1MPa) enters the preheater 1 (the reduction tail gas on the top of the shaft furnace is heat exchanged with natural gas to raise the temperature), the natural gas rises from about 40°C to about 200°C, and then leads to the refined desulfurization process;

[0024] (2) The natural gas with an outlet temperature of about 200°C from the preheater 1 enters the fine desulfurization reactor 2 at a temperature of about 400°C, and the hydrogenation catalyst in the upper part converts the organic sulfur in the natural gas into hydrogen by hydrogenation 2 S, and then use the high-temperature desulfurizer in the lower layer to convert the hydrogenated H 2 S abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com