Drag link ball shell

A technology of spherical shells and tie rods, which is applied in steering rods, steering mechanisms, transportation and packaging, and can solve problems such as unreasonable force on the spherical shells of automotive tie rods, cracks in the spherical shells of automotive tie rods, and wear and tear of the spherical shells of automotive tie rods. , to achieve the effect of reducing friction, not being easily broken by force, and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

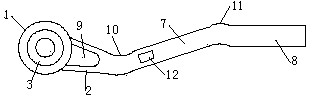

[0008] Combine below figure 1 and figure 2 Specific description embodiment:

[0009] like figure 1 and figure 2 As shown in the drawing, the tie rod spherical shell includes a ball head 1 and a ball handle 2. The ball head 1 is a cylinder with one side protruding in an arc shape, and the ball head 1 is provided with a concave structure. 3. The concave structure 3 runs through the upper and lower end faces of the ball head 1. The concave structure 3 includes an upper hole 4, a middle hole 5 and a lower hole 6. The middle hole 5 is a cylindrical through hole, the upper hole 4 is a conical hole, and the upper hole 4 is a conical hole. The hole 6 shrinks gradually from top to bottom, the upper end of the upper hole 4 and the upper end surface of the ball head 1 have a circular arc transition, the lower end of the upper hole 4 is the upper end of the middle hole 5, the lower hole 6 is a U-shaped hole, and the lower hole 6 The length is greater than the length of the upper hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com