Handheld cutting machine

A cutting machine and hand-held technology, which is applied in the direction of metal sawing equipment, portable motorized devices, sawing machine devices, etc., can solve the problems of increased labor intensity, large processing workload, and low production efficiency, so as to reduce labor intensity and scientific design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

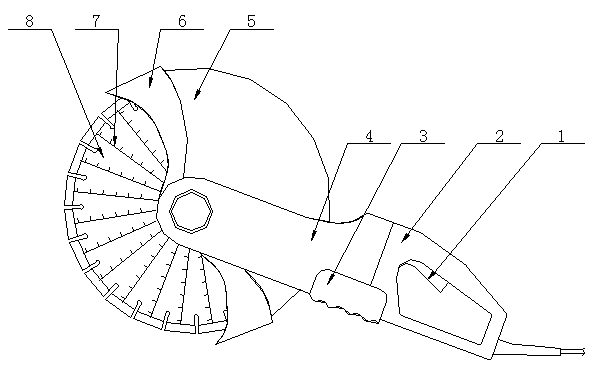

[0013] refer to Figure 1-Figure 2 , the specific embodiment adopts the following technical solutions: it includes a switch 1, a handle 2, a main body 4, an outer cover 5 and a saw blade 8, it also includes a shock absorbing handle 3, a movable cover 6 and a scale line 7, and the rear end of the main body 4 A handle 2 is provided, a switch 1 is provided on the handle 2, a shock-absorbing handle 3 is provided at the lower end of the joint between the main body 4 and the handle 2, a saw blade 8 is provided at the front end of the main body 4, and a cover is provided outside the saw blade 8 5. The upper and lower ends of the outer cover 5 are respectively provided with a movable cover 6, and several scale lines 7 are evenly provided on the saw blade 8.

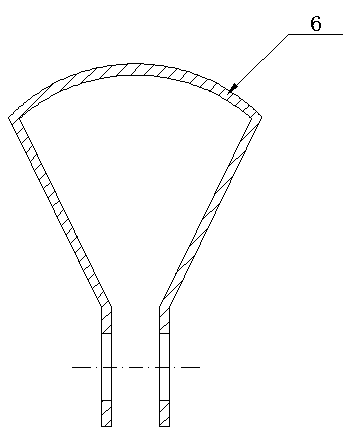

[0014] The section shape of the movable cover 6 is fan-shaped, and the lower end of the movable cover 6 is provided with a hinge hole.

[0015] The principle of this specific embodiment is: when in use, the operator can operate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com