Anti-scaling agent special for seawater and brackish water desalination reverse osmosis membrane and preparation method of anti-scaling agent

A technology of brackish water desalination and reverse osmosis membrane, which is applied in the field of chemical products, can solve the problems of affecting normal use, reducing the probability of scaling, fouling and fouling of membrane elements, etc., and achieves strong dispersion, obvious effect, and easy biodegradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

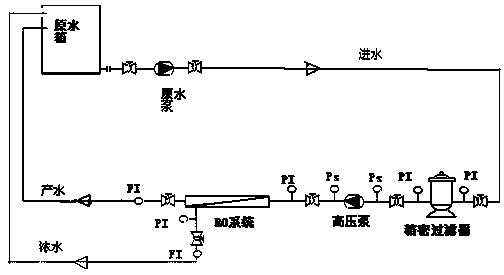

Image

Examples

Embodiment 1

[0027] First add a mixture of 200kg acrylic acid and 300kg 2-acrylamide-2-methylpropanesulfonic acid 50% aqueous solution into titration tank 1, add 100kg ammonium persulfate 20% aqueous solution into titration tank 2, and then add 350kg deionized Water, add 40kg of sodium hypophosphite under stirring, heat to 87°C and drop the materials in two high-level tanks (Titration Tank 1 and Titration Tank 2) at the same time, control the temperature at 90-93°C, finish adding at the same time, cool down to 85°C, Slowly add 10kg of solid ammonium persulfate, then raise the temperature to 93-95°C, keep it warm for 2 hours, and finally lower the temperature below 40°C, open the discharge valve, filter the above liquid medicine into the packaging barrel to obtain the seawater and brackish water desalination reaction of the present invention. Special antiscalant for permeable membrane.

[0028] Experiments were carried out under the following conditions of brackish water quality: pH8.24, co...

Embodiment 2

[0036] First, a mixture of 220kg of acrylic acid and 350kg of 2-acrylamide-2-methylpropanesulfonic acid 40% aqueous solution was added to titration tank 1, 150kg of ammonium persulfate 25% aqueous solution was added to titration tank 2, and then 225kg of deionized water was added to the reaction kettle , add 40kg of sodium hypophosphite under stirring, heat to 87°C and add the materials in two high-level tanks dropwise at the same time, control the temperature at 90-93°C, finish adding at the same time, cool down to 85°C, slowly add 15kg of solid ammonium persulfate and then heat up 93-95 ℃, keep warm for 2.5 hours, finally lower the temperature below 40 ℃, open the discharge valve, filter the above liquid medicine and put it into a packaging barrel to obtain the special antiscalant for seawater and brackish water desalination reverse osmosis membrane of the present invention.

[0037] Experiments were carried out under the following water quality conditions in the Bohai Sea: p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com